Automatic Cartoning Machine DZH-100

Automatic Carton Packing Machine

Anxine’s automatic cartoning machines seamlessly transform your products into market-ready cartons. These systems handle many product types, like blister packs, bottles, tubes, and pouches. They precisely erect, load, and securely seal every carton. Our automated cartoners cut down on manual labor, boost throughput, and ensure consistent, flawless presentation. They’re key for high-volume production and are the strategic choice for top efficiency and a professional finish that elevates your brand.

Description

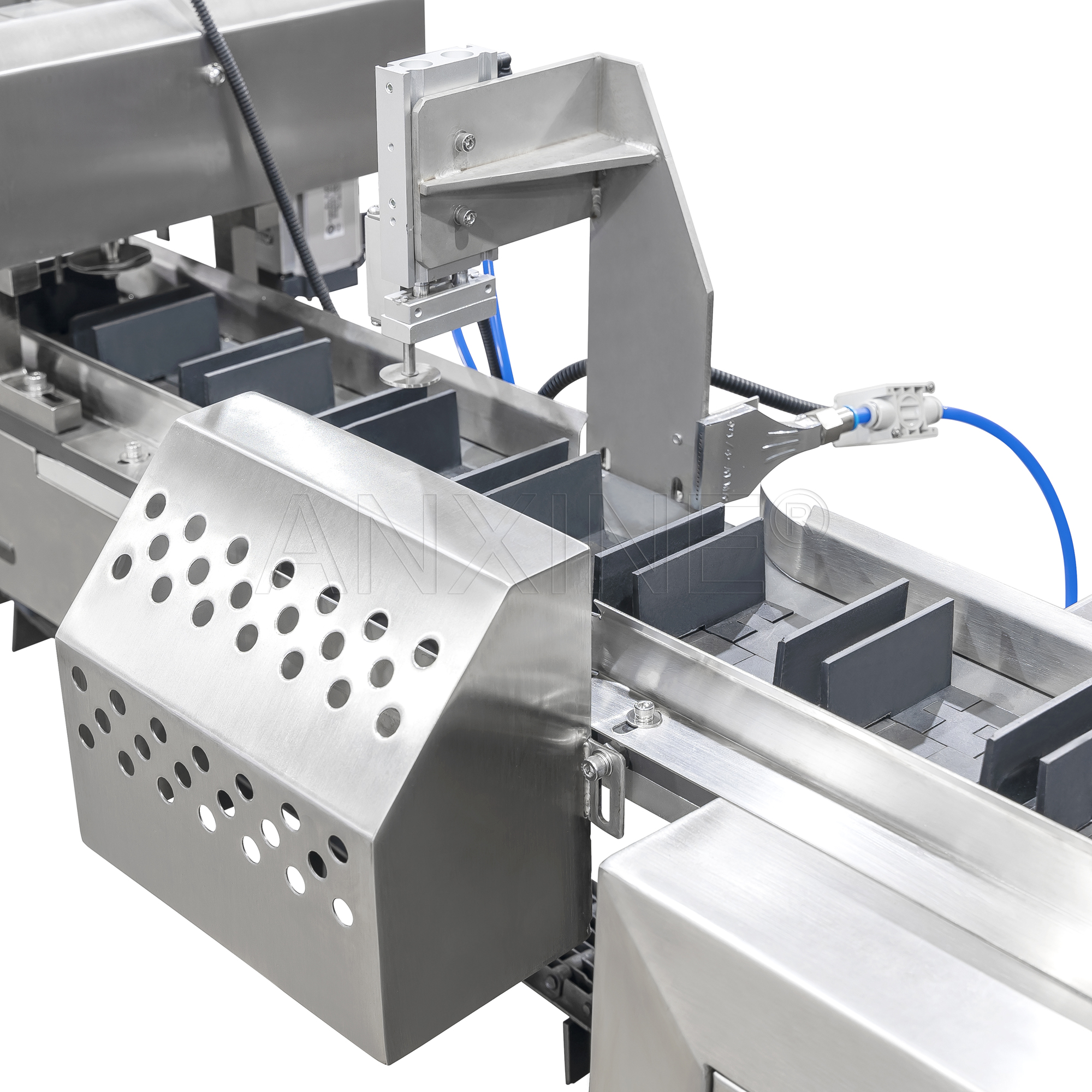

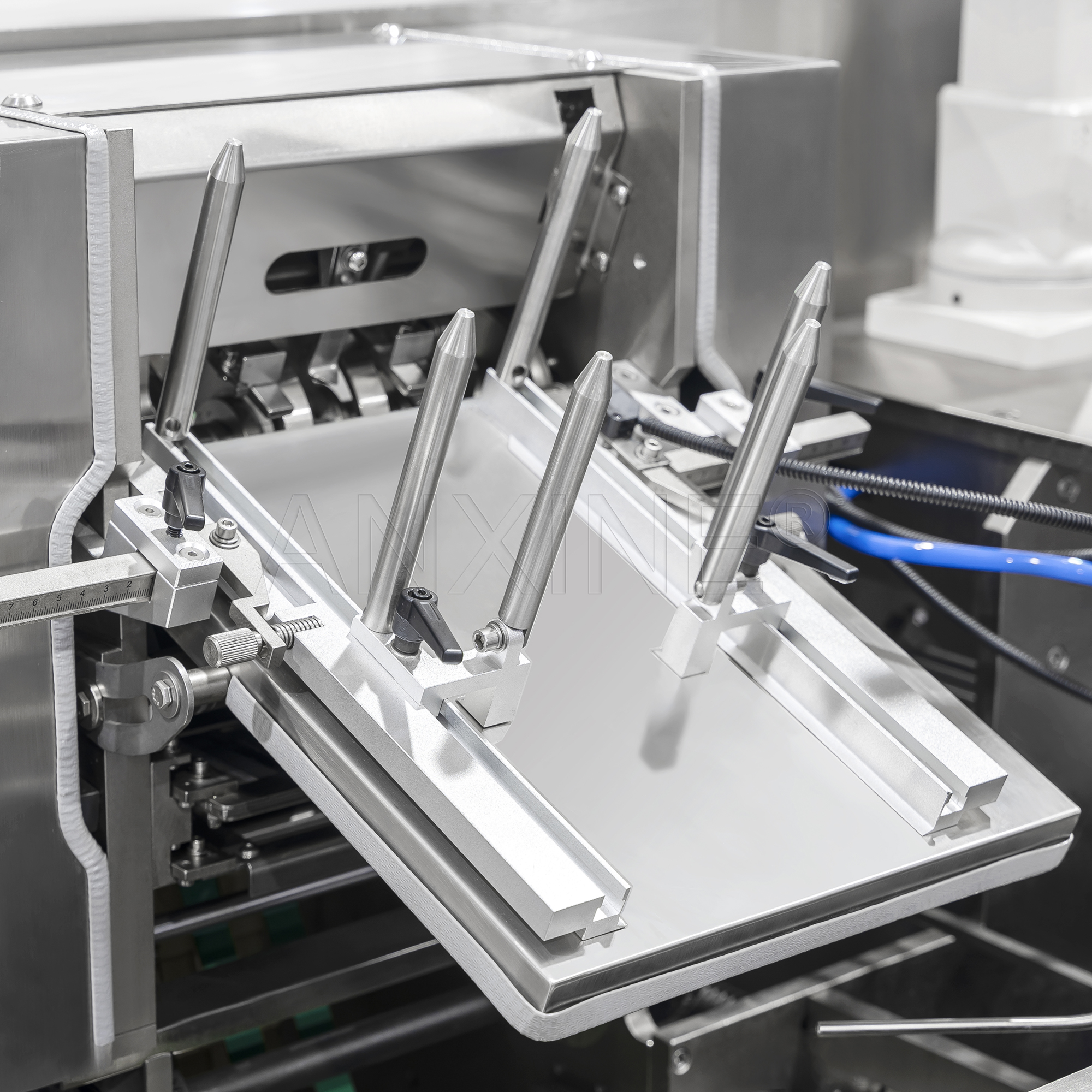

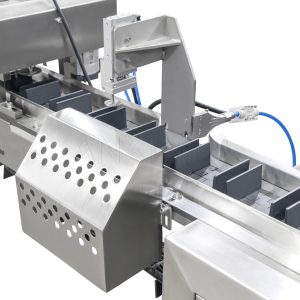

The DZH-100 automatic cartoning machine is an automated equipment designed to meet the precise packaging needs in pharmaceutical, food and other industries. Featuring automated operations for opening cartons, loading products into them and sealing them back up again securely for various sizes and types of carton packaging; its high efficiency and reliability help companies improve production efficiencies as well as ensure consistent product quality.

Highlighted Features

- Fully Automated Process: Each step in this system can be fully automated to reduce manual intervention and increase work efficiency.

- Stable and Reliable Operational Performance: Our precision mechanical structure and high-grade components guarantee stability and long-term operation reliability for an ideal long-term experience.

- Flexible adaptation to multiple specifications: Our carton packaging accommodates diverse product sizes and types for wide application across industries.

- User-Friendly Interface: With its intuitive and straightforward touch screen control panel, it makes setting parameters, monitoring status and diagnosing faults much simpler for users.

- Fine Mechanical Adjustment: For optimal working effect, key parts like carton feeding mechanisms or ear folding mechanisms may require fine mechanical tuning according to specific circumstances and can be fine-tuned according to specific situations in order to reach optimal working effect.

- Safety protection measures: Our machines feature built-in emergency stop buttons and protective doors which may only be opened while running to protect operators safety. In addition, grounding wire must also be connected for electrical safety to reduce electric shock risks.

- Lubrication maintenance: Before production begins, add lubricating oil as part of an effective maintenance program to ensure smooth functioning mechanical parts.

- Real-time monitoring: An operator can observe every part in real-time during machine use to monitor normal functioning conditions and ensure optimal functionality of each part.

Specifications

| Model | DZH-100 |

|---|---|

| Carton | Quality Requirement: 300-350g/m² Size Range: (80-180)mm*(30-95)mm*(15-50)mm |

| Instruction Manual | Quality Requirement: 70-80g/m² Unfolded Size Range: (90-180)mm * (130-240)mm Folded Size Range: (90-170)mm * (25-40)mm |

| Cartoning Speed | 380V 50HZ 3P |

| Power Supply | 1/4HP 15:1 |

| Compressed Air | Working Pressure ≥0.6mpa Air Consumption ≥0.16m³/min |

| Dimensions | 3,200 x 1,150 x 1,700 mm |

| Weight | Approximately 1400kg |

Why Choose Anxine

No Anxiety Needed

With Anxine Machinery, rest assured that you are working with a reliable partner committed to meeting all your machinery and production needs efficiently and effectively.

Exceptional Service

Benefit from our exceptional customer service that includes a 1-year warranty and lifetime support, ensuring your equipment remains in optimal condition for years to come.

Quality Assurance

Our products undergo strict quality control measures to ensure reliability and performance. Anxine Machinery is ISO9001 certified and meets GMP and CE standards, reflecting our commitment to excellence.

Innovative R&D

Our research and development team comprises industry experts and technical professionals who continuously drive product innovation and technological advancements, keeping us at the forefront of the pharmaceutical machinery industry.

Global Support

With a robust global network, Anxine Machinery’s products are exported to over 200 countries and regions. We offer 24/7 support to meet client demands and ensure seamless operation worldwide.

Custom Solutions

We understand that every client has unique requirements. Our team excels in providing highly customized solutions tailored to your specific needs, enhancing your production processes.

We Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Supported by expert custom solutions and a robust global service network.

Capsule Filling Machine

Discover capsule filler machines designed for speed, accuracy, and ease of use in capsule production.

Pill Tablet Press Machine

High-performance compression machines lead to efficient and high-quality tablet production.

Softgel Encapsulation Machine

Softgel capsule making machines are suitable for various capsule sizes, leading to smooth and accurate capsule production in the pharma and nutritional industries.

Gummy Making Machine

Good gummy makers improve your supplement or candy line, ideal for making CBD, vitamins, and fruit gummies in the pharma and confectionery industries.

Industrial Powder Blender

Get smooth and consistent mixtures with our industrial powder mixers—great for pharma, chemical, food and cosmetic use.

Pill Counting Machine

Automate your bottling process with our counting machines. Accurate, reliable, and suitable for pills in all sizes.

Blister Packaging Machine

Blister packaging equipment works well with ALU-PVC and ALU-ALU blisters, suitable for packing tablets, capsules, and softgels. It is always applied in pharmaceutical and supplement production.

Cartoning Machine

We offer China cartoning machines for pharmaceuticals, food, and cosmetics. Our carton machines deliver high performance to meet global packaging needs.

Pouch Filling & Sealing Machine

View our selection of pouch filling and sealing machines made for effective packaging. We provide various solutions for food, pharmaceutical, and other industries with our range of automatic and semi-automated pouch filler machines and pouch sealer machines.

Liquid & Cream Filling Machine

They are used to fill various types of liquids, creams, and viscous products into different containers accurately and efficiently.

Empty Capsules

Stock your line with premium empty capsules—ideal for medicine, supplements, and more—in a full range of sizes and custom options.

TiO₂-Free Capsules

Switch to our TiO₂-free capsules for safer, more reliable protection of your products.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288

Zhejiang, China (GMT+08)