What is an Industrial Powder Blender?

This industrial powder mixer blends different dry powders into a uniform and consistent mix. In many industries, the quality of the final product depends on how well the powders are mixed. For example, in pharmaceuticals, active ingredients and excipients must be evenly distributed. It makes sure each tablet or capsule has the right amount of medicine.

Whether you want to make capsules or tablets, consistent powder mixing is always needed. So a high-quality powder mixer is key to your production.

Besides quality, powder mixing also directly influences product safety and efficiency. It helps distribute the materials evenly and ensures treatment effectiveness in pharma production. In food production, good mixing creates uniform flavor, texture, and nutrition. Thus, every product tastes and looks the same. In chemicals and cosmetics, proper mixing helps maintain product stability and color.

Good powder mixing also reduces production problems, such as uneven coating and segregation. It improves process efficiency, and helps companies meet strict quality standards. Without proper mixing, even high-quality raw materials may not deliver the expected final product.

Common Industrial Powder Blender Types

A powder mixing machine moves powders in a way that makes the particles spread out and blend together. This process lasts until powders form a uniform mixture. The mixing method varies based on the type of mixer.

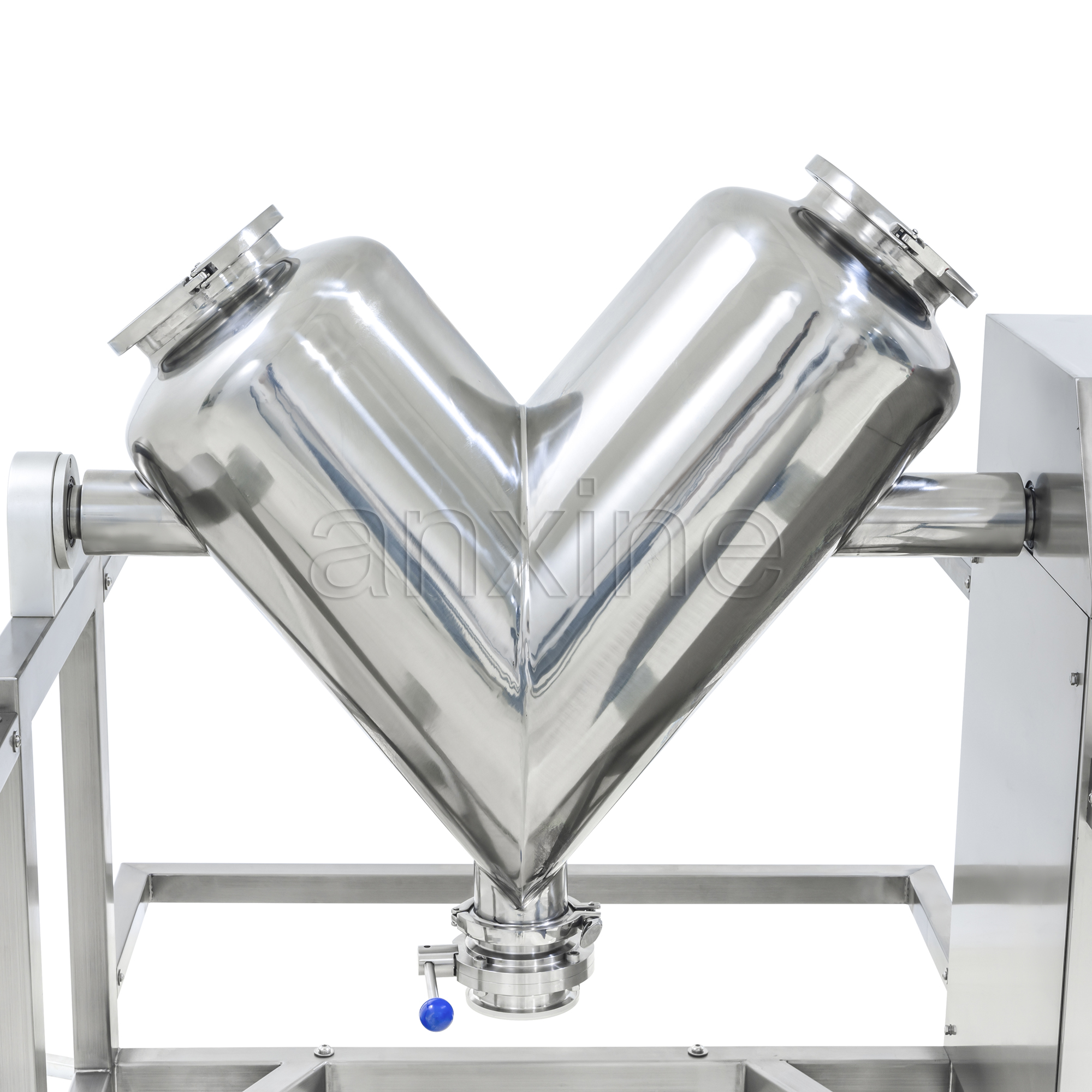

V Blender

The V-blender has two hollow cylinders linked in a V-shape. It relies on the rotation for powder tumbling and mixing thoroughly. The powder mixer machine ensures even distribution of all particles when not generating much shear or heat.

The key parts of the V blender machine include the V-shaped mixing chamber, rotating shaft, drive motor, discharge valve, and safety covers. They work together to produce consistent mixing. Also, they need regular maintenance for good operation. Because this powder blending machine provides gentle blending, it is ideal for fragile or crystalline powders like active ingredients.

Cone Powder Mixer Machine

A cone blender machine is designed with a conical-shaped chamber that rotates to get uniform mixing. The cone structure helps powders tumble and flow smoothly. It reduces the chance of material buildup or dead spots inside the chamber.

This powder mixing machine is divided into single and double cone mixers. A double cone mixer is ideal for free-flowing powders, fragile particles, and heat-sensitive materials. On the other hand, a single cone mixer is suitable for powders and granules with poor flowability or large differences in particle size. You can choose the right one based on your production needs.

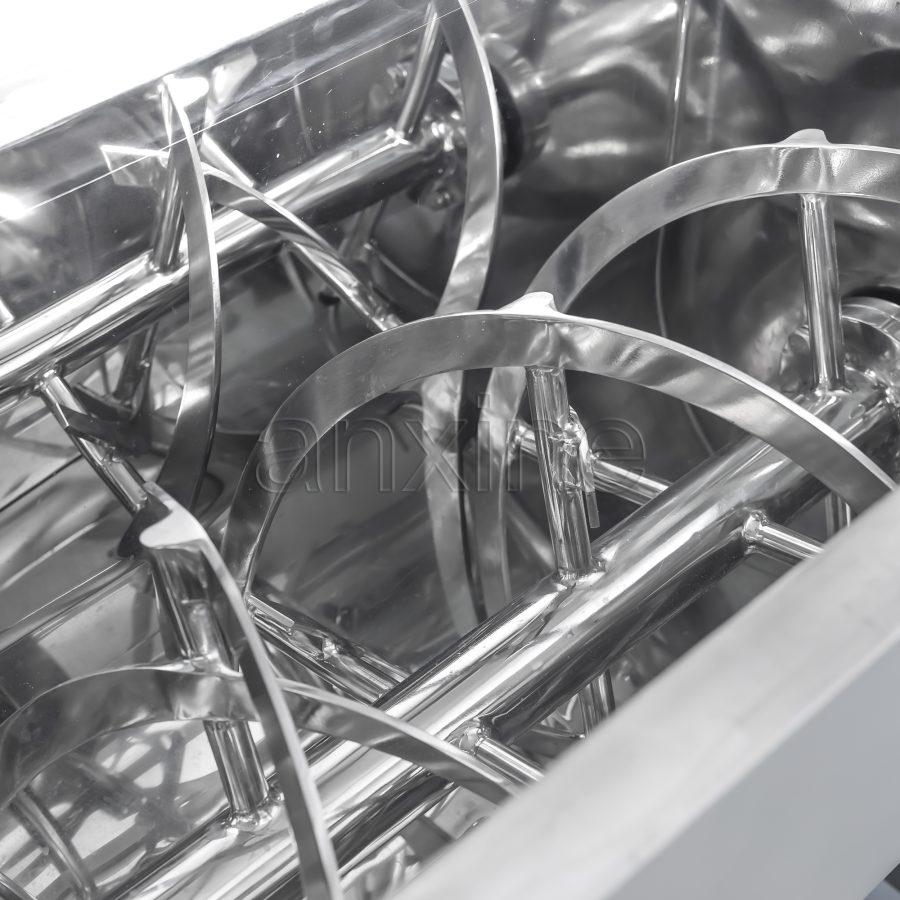

Ribbon Blending Machine

The ribbon blender mixer is a horizontal machine. It features a U-shaped trough and a central shaft with inner and outer helical ribbons. Its operation is based on counter-current movement. The inner ribbon pushes materials outward, while the outer ribbon moves them inward. It creates a continuous circulation that mixes powders thoroughly.

Because of its design, it can handle large volumes of powder for fast and uniform mixing. Ribbon mixers are widely used in industries such as food, nutritional supplements, and chemicals. They can blend protein powders, flour blends, spices, etc.

3D Powder Mixer Machine

The 3D Powder Mixer depends on complex spatial movement to achieve uniform blending. It moves the mixing barrel in multiple directions at the same time. This three-dimensional motion makes the powder constantly move positions and mix thoroughly. As a result, powders are evenly distributed with high mixing uniformity quickly.

The 3D powder mixer is widely used to mix materials in small to medium batches. It ensures uniformity in each dose. It is also common in food for nutritional powders, coffee, and flavor mixing, chemicals to mix pigments, and cosmetics. This powder mixing equipment is especially ideal for powders with different particle sizes, shapes, or densities that are often hard to mix evenly with simple-design machines.

Key Factors to Select the Right Powder Mixer

Material Properties

At first, you need to consider the properties of powders. Free-flowing powders such as milk powder, sugar, or salt can be mixed with simple gravity-based mixers like V-blenders or double-cone mixers. Sticky, fine, or powders with very different particle sizes may require a 3D mixer to achieve uniformity. If liquids need to be added to powders, a high-shear mixer is more suitable.

Production Volume

It decides the size and type of mixer you need. The right size prevents both underuse and overloading. If you run a small-scale business, such as laboratories or startups, compact mixers like 3D powder mixer machines or V-blenders are better. If you own a medium to large-scale factory, you may use ribbon mixers or large double-cone mixers.

Cost

This is another important consideration. Different powder blending machines vary greatly in price and complexity. Ribbon mixers are usually cost-effective for large-scale production but require more energy. 3D mixers are generally more expensive and limited in batch size. The long-term costs should also be considered. It includes the fee of spare parts, energy, and operator training.

How to Maintain a Powder Mixer Machine?

To keep a powder mixing machine running smoothly and efficiently, maintenance is a must.

Regular cleaning

Powder blenders must be cleaned after each batch. It avoids cross-contamination, especially in food and pharmaceutical industries. You could use brushes, compressed air, or gentle vacuuming for dry cleaning. Food-grade detergents or sanitizing agents are ideal for wet cleaning if the material allows. Also, don’t forget to clean the corners, seals, and discharge valves. They are easily to accumulate powders.

Lubrication

Lubrication is required weekly or monthly. Key parts like bearings and gears should be lubricated according to the manufacturer’s schedule. Proper lubrication reduces friction, prevents overheating, and extends the life of the powder blending machine.

Regular Inspection

Seals and gaskets prevent powder leakage and keep contaminants out. Over time, they can wear, harden, or crack. So you need to inspect these parts regularly and replace them when needed. A damaged seal can lead to product loss and possible contamination.

Why Should You Choose Anxine Powder Mixer?

Anxine supports a complete and high-quality product chain from design to manufacturing. We provide a wide range of machines, including powder mixers, capsule fillers, and tablet presses.

One-stop Service

We provide one-stop procurement solutions for complete production needs. From mixing equipment to filling, sealing, and packaging machines, you can find all you need. This not only saves time and cost but also ensures that every piece of equipment works seamlessly together. We also have a professional team to offer you expert guidance about purchase or customization. It makes the entire purchasing process smooth and efficient.

Certified Equipment for Worldwide Compliance

All our machines meet strict international standards such as GMP, CE, and ISO certifications. This guarantees not only reliable performance but also high compliance for pharmaceuticals, food, and chemical industries. They help you get safety, quality, and consistent production.