Why do you need a machine to help with bottle packaging?

When dealing with bottle packaging, some supporting equipment is needed. They help a lot in production. Bottle packaging becomes faster and more accurate.

Without auxiliary equipment, you may need to do many manual tasks, such as sorting bottles. This can slow down production and cause errors. Auxiliary machines take over these tasks. It reduces human effort and improves efficiency. Take bottle unscramblers for example. They handle large numbers of bottles in a short time. This not only boosts output but also ensures a consistent process.

Common types of bottle auxiliary machines

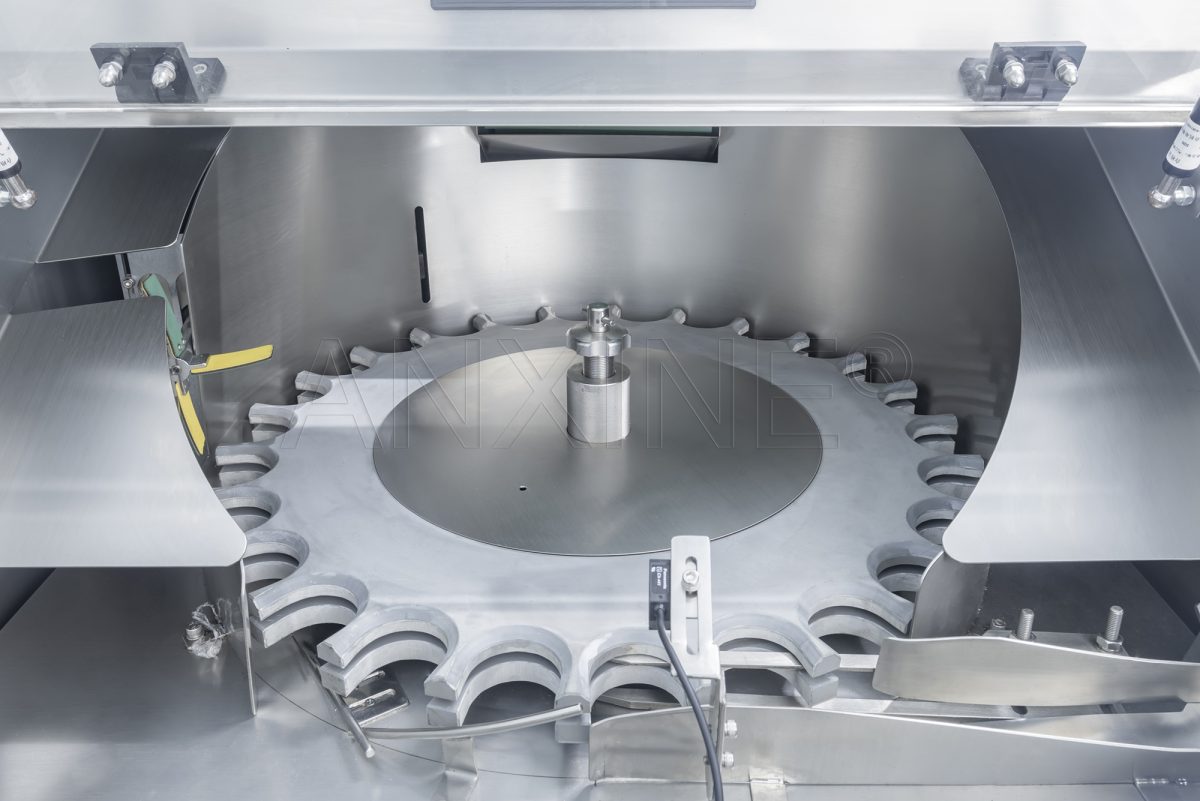

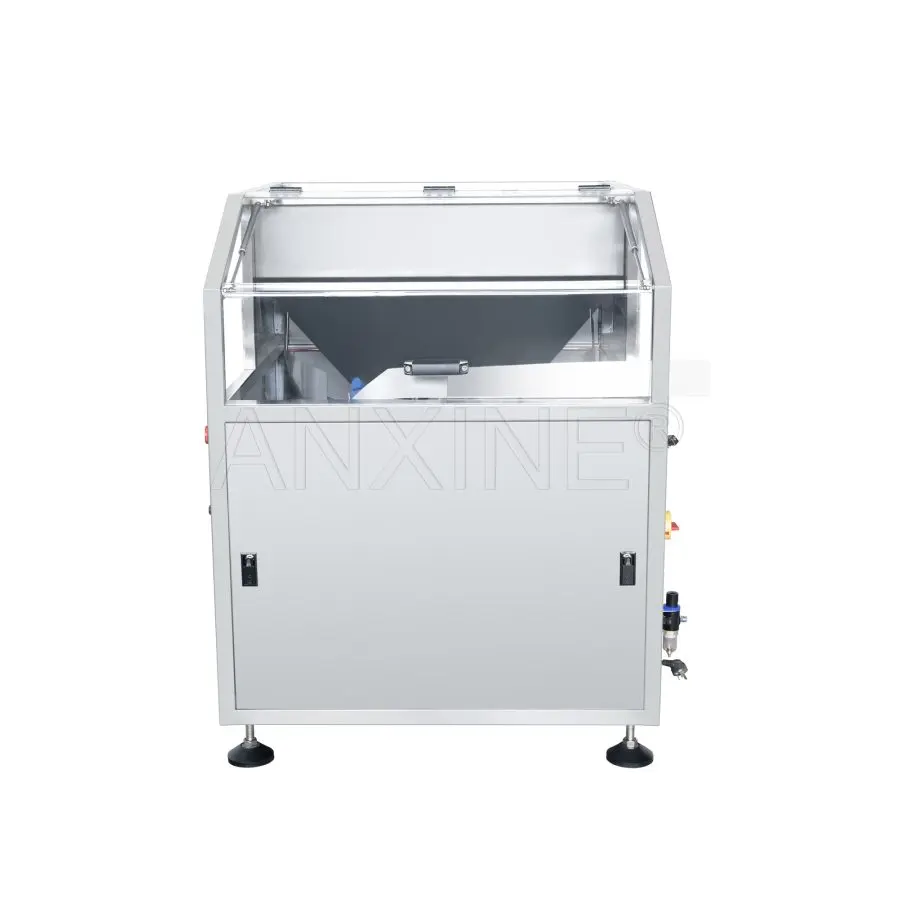

Bottle unscramblers

A bottle unscrambler could take randomly placed bottles from a bulk supply. Then it arranges them in the correct position for filling and capping. The unscrambler automatically sorts and orients each bottle. It makes sure they stand upright and face the right direction before the next stage.

This machine is especially useful for lightweight plastic bottles or PET bottles. These bottles can easily tip over if not placed correctly. By keeping the bottles aligned, the unscrambler reduces jams and prevents damage. It also helps maintain consistent speed across the line. This is important for high-volume production in industries like pharmaceuticals.

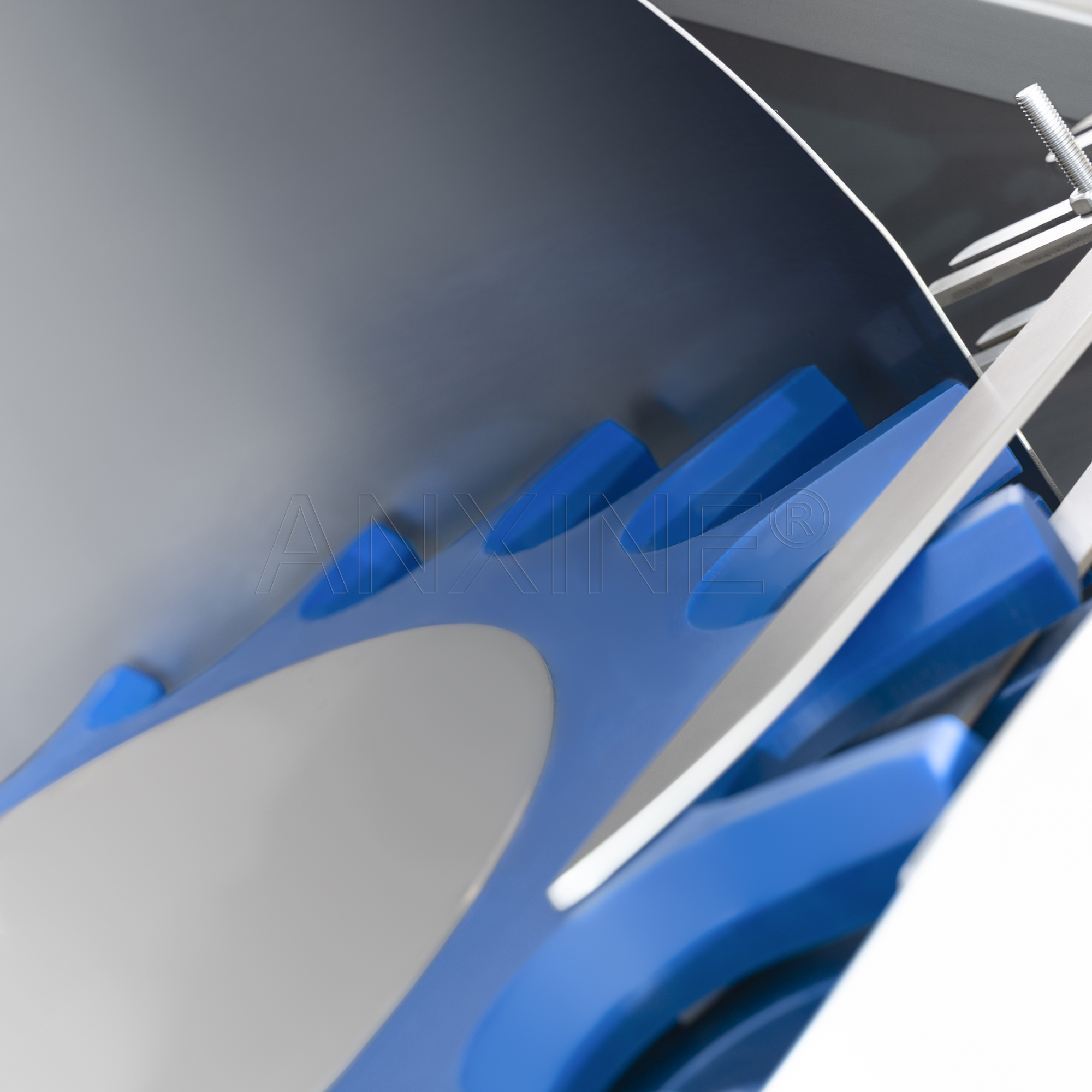

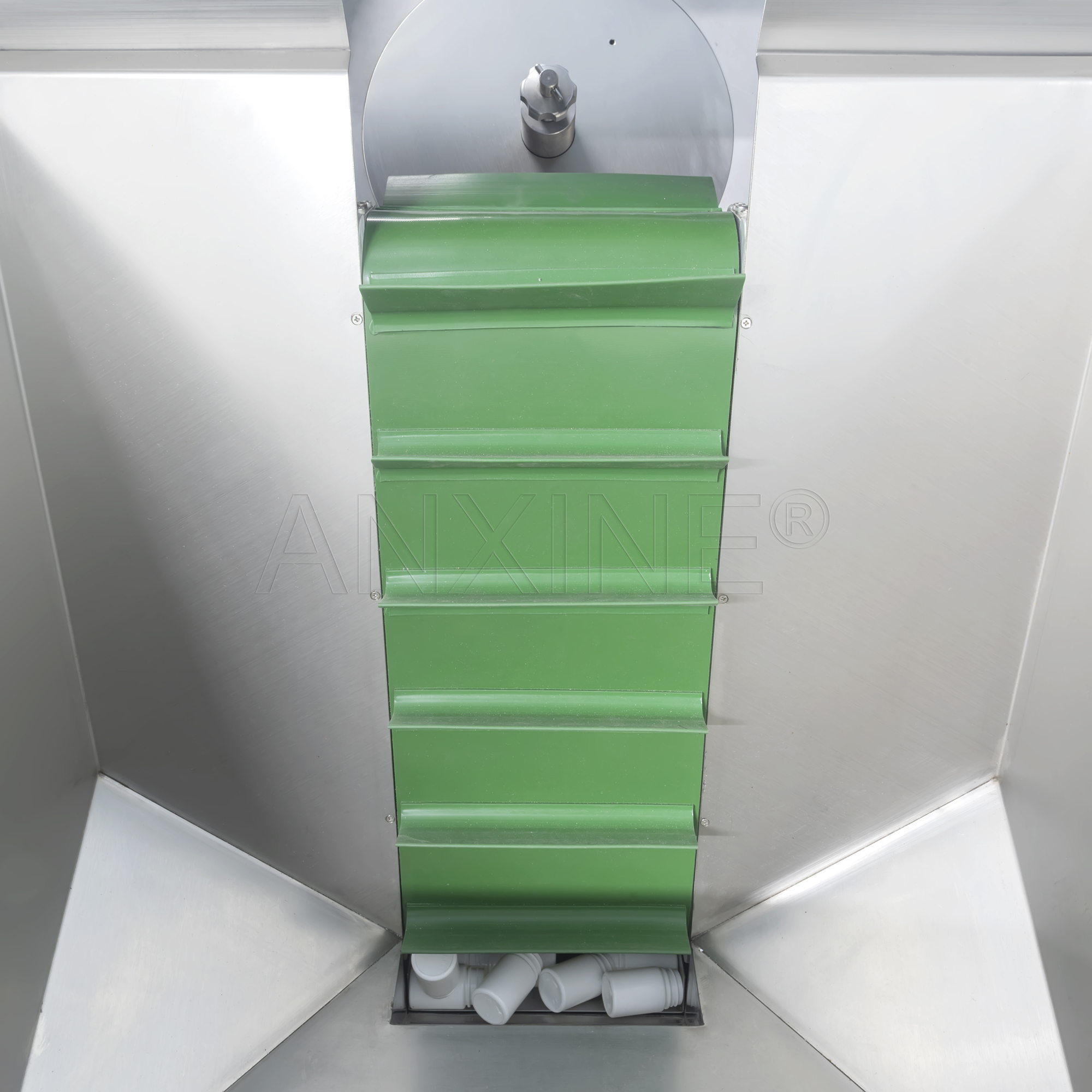

Automatic cotton inserting machine

It is designed to place cotton, polyester or rayon into bottles. The process is always after filling and before capping. It protects tablets, capsules, or softgels inside the bottle during transport. The cotton holds the product firmly in place. It prevents breakage or damage caused by movement.

The machine cuts cotton into required lengths, and shapes it into uniform strips. Then it automatically inserts the cotton into each bottle. The whole process is precise to ensure that every bottle receives the right amount of cotton. Compared with manual cotton inserting, this method is faster and more hygienic.

Automatic cotton inserting machines can handle different bottle sizes and cotton lengths. They are suitable for various packaging needs. The equipment often features bottle detection sensors. They prevent cotton from being inserted if a bottle is missing or out of place. Some models can also adjust speed to match filling speed.

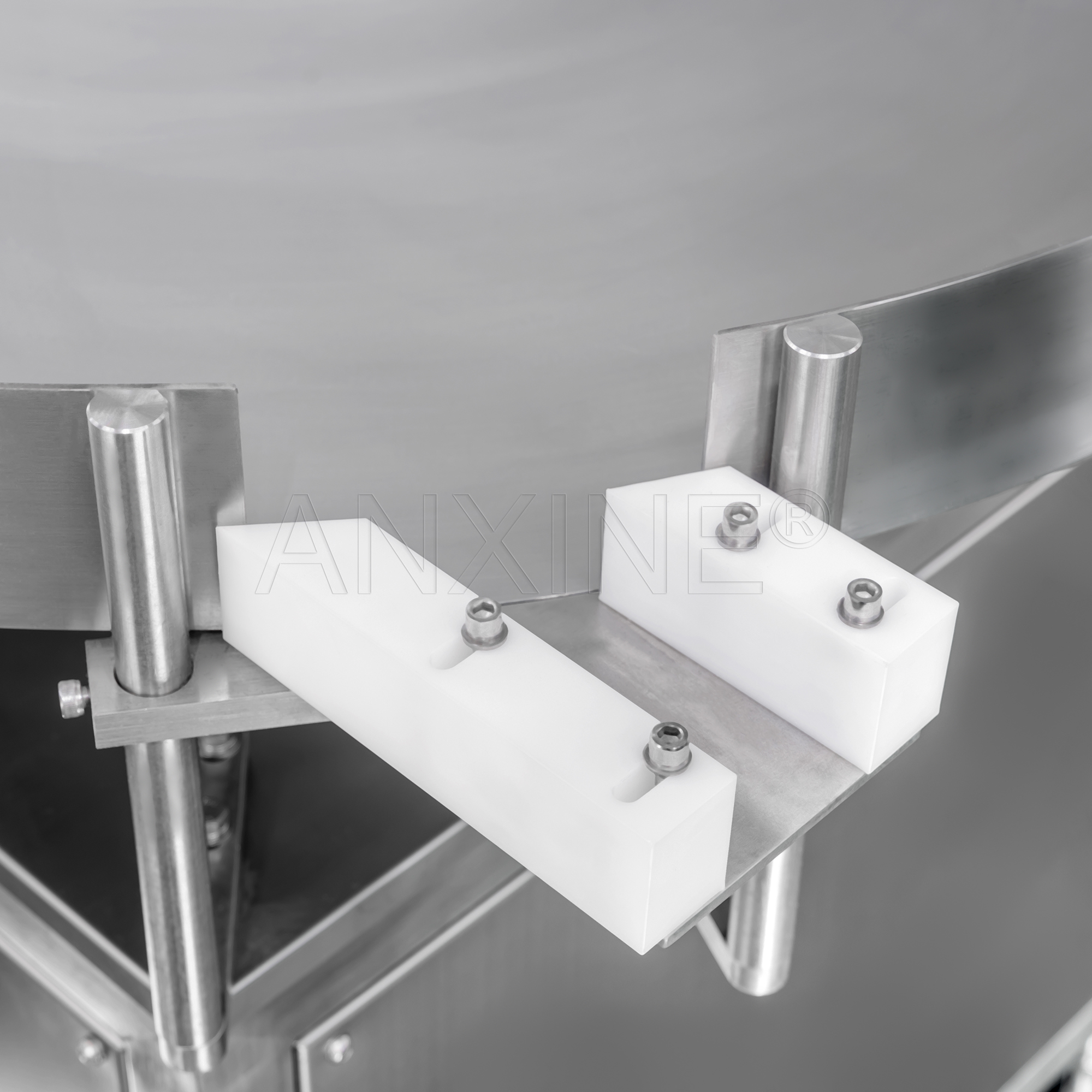

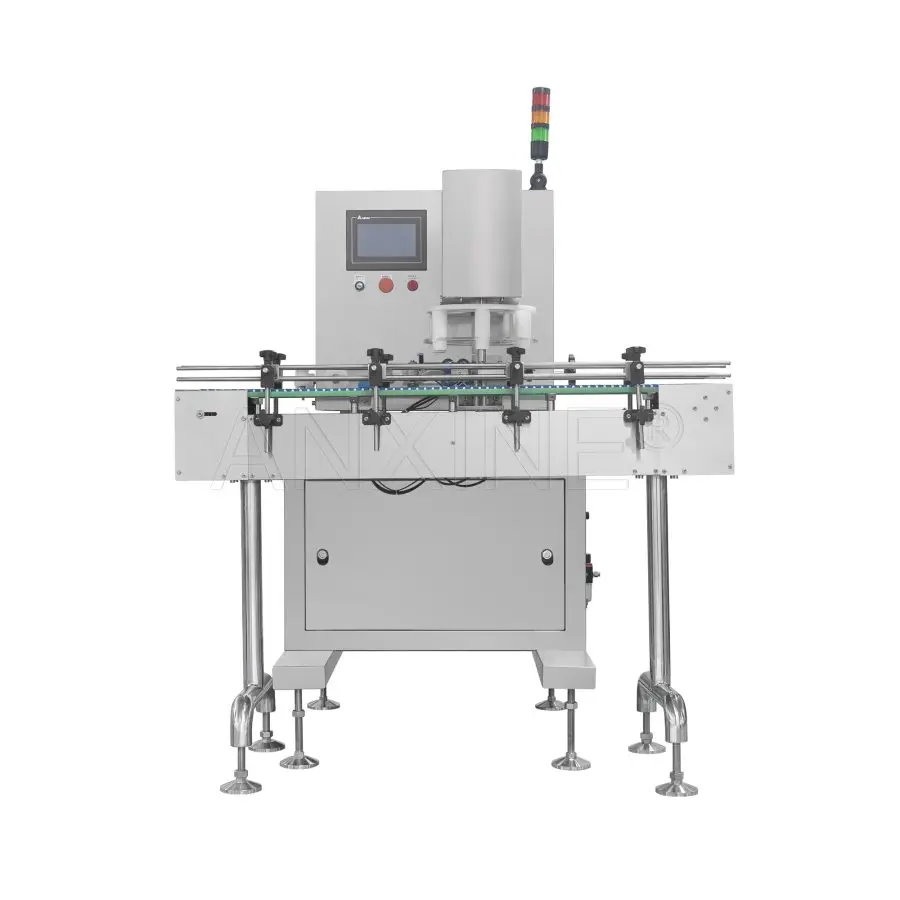

Automatic desiccant inserting equipment

It is used to place desiccant packets or canisters into bottles before sealing. Desiccants absorb moisture inside the container. It could protect tablets, capsules, and other sensitive products from humidity damage. This step is especially important, because moisture can reduce product stability.

Modern desiccant inserters can handle different packaging materials, including pouches and strips. They can also be adjusted for various bottle sizes and production speeds. This allows easy integration into existing packaging lines. With fully automated operation, they reduce manual handling and improve hygiene.

Applications in different industries

There are many uses of bottle auxiliary equipment during production. Here are some examples for your reference.

Pharmaceuticals

In this area, they are important for packing tablets, capsules, and liquid medicines. They help keep medicines safe, clean, and stable during storage and transport.

Nutraceuticals and supplements

For vitamins, herbal capsules, and dietary supplements, auxiliary machines ensure efficient packaging. They support high speed and good product safety for production.

Food and beverages

Auxiliary machines are widely used in food and drink packaging lines. For example, bottle washers help prepare containers before filling juices or sauces. With these machines, you can achieve higher output while maintaining safety standards.

Cosmetics and personal care

In cosmetics, auxiliary machines handle bottles for lotions, shampoos, creams, and perfumes. Though they have special shapes, these machines handle them smoothly without causing damage.

Chemicals

Auxiliary machines support the packaging of household cleaners, industrial solutions, and other chemicals. For example, conveyors and turntables ensure safe movement between stations. Auxiliary machines reduce risks and make packaging lines more reliable.

Why choose Anxine to support your bottle packaging?

Anxine offers different types of auxiliary equipment, including bottle unscramblers. Whether for small batches or high-speed operations, we are your good partner for cooperation.

Custom solutions

Every production line is different, and so are the challenges it faces. Our team designs bottle auxiliary machines that fit your exact needs. If you need adjustment for special bottle shapes or require a matching high-speed output, we can conduct it as required. Besides, extra safety features could be added if needed. With customized solutions, your packaging process becomes smoother and more efficient.

Global support

Anxine Machinery serves customers in more than 200 countries and regions. We build a strong worldwide network for support. We offer 24/7 service. No matter where you are, you have quick solutions to keep everything running smoothly.