What is a Powder Grinder Machine?

A powder grinder machine is used to turn solid raw materials into fine, uniform powders. It takes larger chunks or particles and breaks them into smaller pieces. The ground material becomes much easier to manage and process. With a grinder machine, your later production steps, like blending, filling, and packaging, can be performed more efficiently. Whether handling pharmaceuticals, nutraceuticals, food, or chemicals, it is a must-have tool for improving the quality of your product.

How Does a Powder Grinding Machine Work?

Materials are loaded into the grinder via a feed inlet or hopper. A rotor, inside the machine, rotates to crush the material and grind it into finer particles. The powder mill equipment often includes filters or classifiers to ensure that the material is ground to the desired size. To prevent overheating, many powder grinder machines have a cooling system. Once the material reaches the required fineness, it exits through a discharge port or outlet.

Main Parts of a Powder Grinding Machine

Feed Inlet/Hopper

This component introduces raw materials into the machine. It ensures a steady material flow into the grinding chamber.

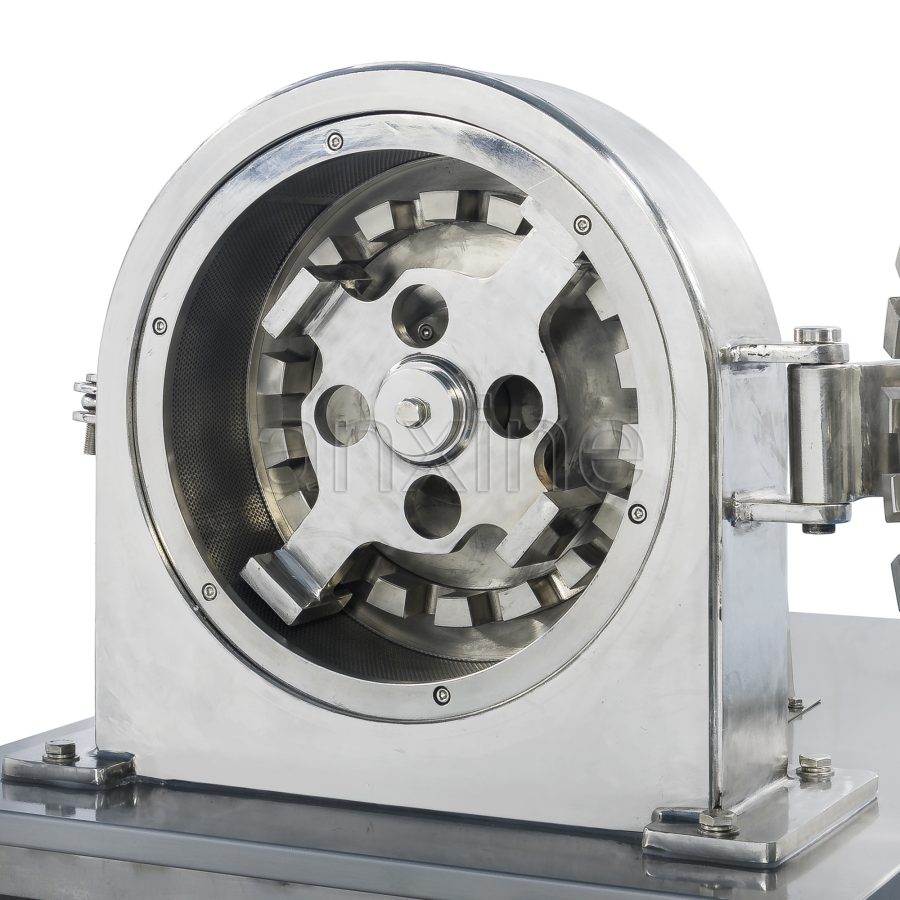

Grinding Chamber

This is the core of the powder grinder machine. The chamber houses the grinding elements like blades or hammers. These grinding components work by impact and shear to crush raw materials into finer particles.

Vibrating Mechanism

Some grinders include a built-in vibration system. It enables the material to enter the machine more smoothly. Also, it helps prevent material build-up or clogging inside the machine.

Screen

This component sits right at the exit point of the grinding chamber. It can be customized with different mesh sizes to control the powder fineness.

Motor Unit

This is where the grinding mechanism gets power. It ensures the machine performs in a stable and consistent manner.

Dust Collection System

Some advanced grinding machines have this component. It captures airborne powder to keep your facility clean and safe.

Control Panel

It allows operators to adjust machine settings. It may include controls for speed, grinding time, or just simple ON/OFF buttons.

Finished Product Collector

As the name implies, this component is used to gather the final powder. It makes it easier to transfer the product to packaging or storage.

Applications of Powder Grinding Machines

As we mentioned above, powder grinding machines are a versatile processing tool. Now, let’s take a closer look at what they can actually do across different sectors.

Food Industry: The grinding process enhances the flavor, texture, and even shelf life of food products. It’s also a good way to reduce food waste. Powder grinders can work with all food products that should end up in powder form. They efficiently turn spices, grains, sugar, coffee beans, and other food ingredients into finer particles.

Pharmaceutical Industry: Fine powders allow medications to be more easily absorbed by the body. Powdery products also make it easier to measure the precise amount of drug in each dose. That’s where a grinder machine comes into play. Whether your pharma products are for external or internal use (topical treatments or oral solid dosages), the machine guarantees the efficacy, safety, and quality.

Cosmetics Industry: Many cosmetic products are in powder form, like loose powder, pressed powder, translucent powder, and more. If these formulations fail to have a uniform particle size, your beauty brand won’t catch on. Powder grinders can process a variety of materials, including talc, pigments, and other ingredients. They enhance the skin feel and color distribution of makeup products.

Chemical Industry: In chemical manufacturing, many raw materials need to be ground into an ultra-fine powder form. This step ensures products like paints, coatings, and adhesives end up with uniform color consistency and stability. Grinding machines can achieve the right particle size and help deliver consistent quality and performance across these chemical products.

Why Choose Anxine Powder Grinder Machines?

At Anxine, we design our Powder Grinder Machine to deliver fast, clean, and reliable powder processing results. Our product line covers from compact desktop grinders to fully automatic continuous machines. Whether you’re handling pharmaceuticals, food ingredients, or herbal extracts, Anxine gives you a grinding solution that saves time, reduces waste, and keeps your production on track.

- Robust and fully GMP-compliant stainless-steel construction

- Customizable mesh sizes for different levels of powder fineness

- Efficient cyclone separator to improve powder product quality

- Built-in dust collection and low-noise operation

- Simple controls and easy-to-remove grinding components

- Air cooling unit for stable temperature during grinding

- Secure locking and overload protection