What is a Tablet and Capsule Inspection Machine?

A tablet and capsule inspection machine is an indispensable device used in pharmaceutical and nutraceutical manufacturing. The equipment is engineered to check tablets and capsules for defects or contamination. It relies on various technologies to carry out external and internal inspections for products. Fitted to different scenarios, the machine can stand alone or sit in a line.

Most automated inspection systems integrate a rejection mechanism to remove the faulty products. The main goal of a tablet and capsule inspection machine is to ensure quality and compliance before products leave the manufacturing facility.

Types of Tablet and Capsule Inspection Machines

Like any machine out there, inspection equipment can be manual or automatic, which is the simplest way to classify them. But to give you a clearer understanding of these machines, we’d like to categorize them by their inspection target—internal for metal fragments and external for physical defects.

Tablet and Capsule Inspection Systems (for Internal Targets)

These are built to find hidden issues. They look inside tablets, capsules, and even their packaging for foreign objects or missing material. They catch defects that are not visible on the surface.

Pharmaceutical Metal Detectors

These are specifically used to look for traces of metal inside tablets and capsules. They come with coils that generate electromagnetic fields to scan each pill and find the faulty one. These inspection machines can hunt down metal contaminants like stainless steel, ferrous, non-ferrous, magnetic, and non-magnetic metals.

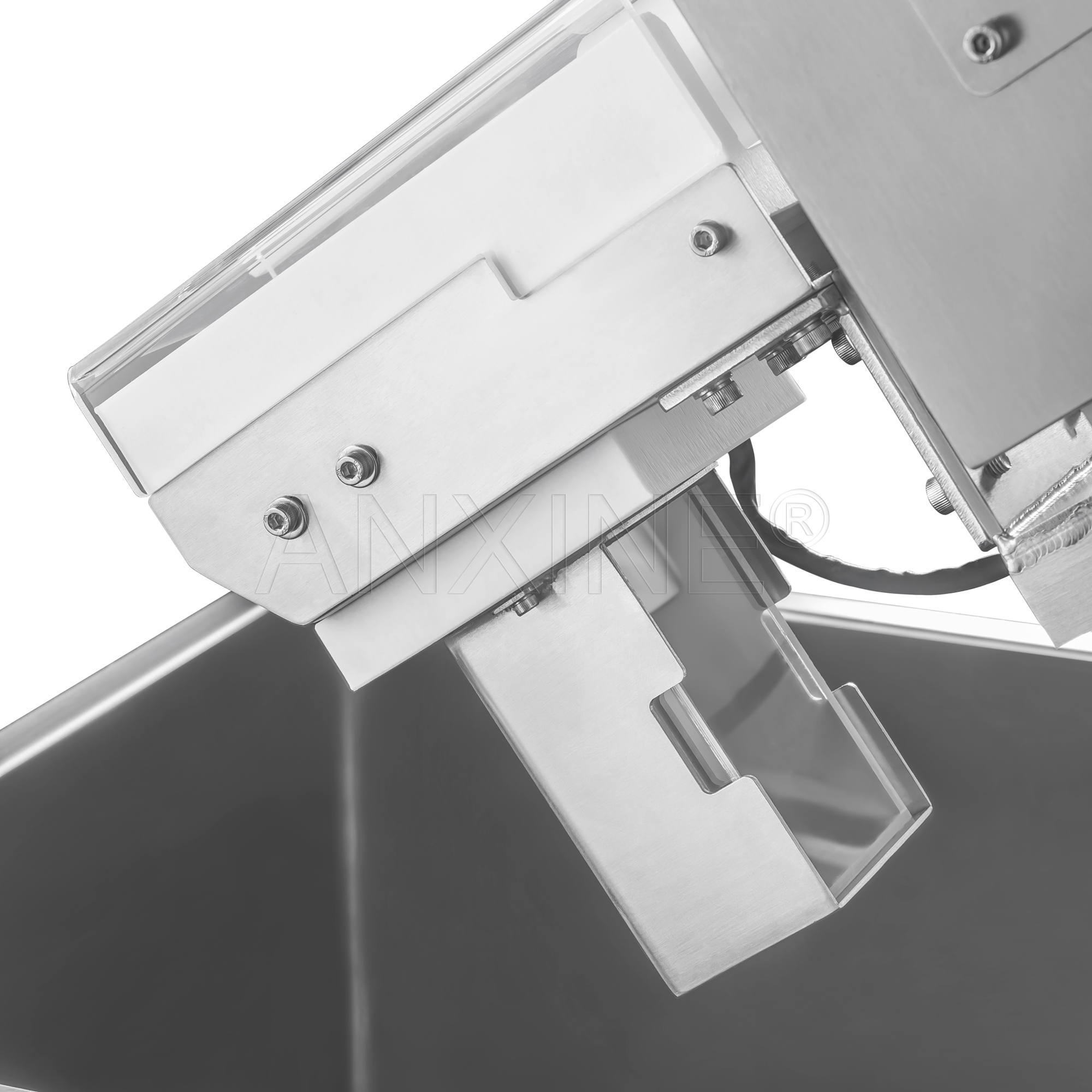

All pharma metal detectors feature a reject system, whether it’s a compact standalone or a conveyor unit. The reject system may be a pusher, a diverter gate, or just a burst of air. If a tablet or capsule contains metal, the system removes it immediately.

X-ray Systems

X-rays provide a deeper view inside products. Unlike pharma metal detectors that only work on metal contaminants, these systems can detect non-metallic foreign objects like glass, plastic, and rubber. They can also check for missing or broken products in bottles and blister packs. These inspection machines are highly reliable in high-output lines.

Tablet and Capsule Inspection Machines (for External Targets)

These machines focus on the appearance of the tablet or capsule. They identify quality problems relating to shape, color, printing, and other surface flaws that can be seen with the eye.

Depending on the means of inspection, these can be further grouped into:

Manual Visual Inspection Machines

These machines rely on trained human operators to visually check products. They typically consist of a vibration mechanism for shaking off dust on the capsule or tablet, an inspection station (with adjustable overhead lighting, a mirror, and a roller conveyor) for optimal detection, a foot pedal to stop or pause the conveyor for closer examination, and a vacuum pen for picking up the faulty units.

Manual visual inspection systems are useful for small batches, R&D labs, or as a secondary quality check. But the downside is that the outcome may be affected by human factors like fatigue, attention span, and skill levels.

Automatic Visual Inspection Machines

Rather than using the human eye, these systems employ more advanced tools. They feature high-resolution cameras, lighting, sensors, and software to check the capsule or tablet and reject the faulty one automatically.

These visual inspection machines have a specialized mechanism that flips tablets or spins capsules. This action gives the camera a full 360° perspective for inspection. Captured images are analyzed instantly by the software.

This type of visual inspection machine aims to find any cracks, chips, dents, or stains on the outer appearance of the product. Compared to naked-eye checks, they ensure inspections are faster and more reliable.

Benefits of Tablet and Capsule Inspection Machines

They keep patients safe. Faulty tablets or capsules are removed before they leave the factory. A metal detector can pull out a pill with a tiny steel shard. An X-ray can flag a capsule that isn’t filled correctly.

They make products look the same. Customers trust a medicine when every piece is uniform. Camera systems catch cracks, chips, or off-color capsules. On smaller runs, staff at a manual station can still spot defects quickly.

They save time. Modern inspection machines can check thousands of tablets or capsules in an hour. Bad ones are rejected on the spot, so staff don’t waste hours sorting by hand.

They cut waste. Defects are stopped early, before bottles or cartons are filled. Catching a broken tablet right after compression means the whole bottle isn’t lost later.

They help with compliance. Many machines log what was rejected and why. This record is proper during audits and proves that every batch was checked.

Applications of Tablet and Capsule Inspection Machines

In pharmaceutical and nutraceutical plants, they are placed right after tablet presses and capsule fillers. This is where empty capsules or chipped tablets are most common. Rejecting faulty pieces early can ensure reliable bottling or blister packaging.

What if the products have been packaged? These inspection machines can still provide you with a secondary check. Systems like X-ray and conveyor metal detectors scan blister packs, bottles, or pouches for foreign particles or missing products. Any defective package is rejected before case packing or shipping.

Manual inspection stations are still widely used in smaller operations or R&D labs. Operators review tablets or capsules by eye and remove defectives. Though slower, the machine is helpful in these particular settings.

Why Choose Anxine Inspection & Rejection Machines?

At Anxine, we offer internal and external inspection solutions for your tablets and capsules. From standalone and in-line metal detectors to manual inspection tables and automatic visual inspection machines, each unit helps your products meet the highest quality standards.

- Offers a full range of inspection technologies tailored to various scales

- Features built-in reject, pill sorting, and options that pair with other equipment

- Finds various defects and foreign objects visible or hidden in tablets and capsules

- Integration-ready auxiliary equipment and line compatibility

- Built for regulated environments with clean construction and stable accuracy