What Is a Cartoning Machine?

Cartons are a common form of secondary packaging. A cartoning machine, as its name suggests, is specifically used to form and seal such packaging. Also called a cartoner, this machine creates an extra protective layer for your product, improves appeal, and makes storage and shipping easier. Cartoning machines can handle bottles, pouches, blister packs, and many other primary packages in an automated manner. As a key part of secondary packaging operations, these machines are widely used across industries like pharmaceuticals, food and beverage, cosmetics, and consumer goods.

Types of Cartoning Machines

Cartoning machines come in different layouts and automation levels to handle a wide range of products and packaging needs. Knowing the main types helps you match the right cartoner to your production goals.

Horizontal Cartoning Machines

In these machines, cartons are erected and moved sideways. Products are pushed into each carton from the side. For this reason, this type is also known as end-load cartoners. This design works well for flat or stackable items like blister packs, sachets, tubes, or soap bars. The horizontal cartoner machine is preferred for high-speed production lines because it can handle continuous motion and integrate easily with upstream equipment like blister or pouch machines. They can include options for leaflet insertion, printing, or glue sealing, making them highly adaptable for pharmaceuticals, cosmetics, and food products.

Vertical Cartoning Machines

These machines form cartons and load products in a different direction. They’re also called top-load cartoners. They erect cartons vertically and drop products from the top into the cartons. This type is ideal for bottles, jars, or pouches that cannot be easily pushed horizontally. Carton packaging machines are common in the pharma, food, and chemical industries for items like syrup bottles, snacks, milk powder, or hardware kits. Many top-load cartoners are arranged in a rotary manner. The mechanism allows for continuous, high-speed operation.

Cartoning Machine Working Principle

All cartoning machines aim to do the same thing: form, fill, and seal cartons with speed and precision. But each design handles products a bit differently. Here’s how the main types operate.

How a Horizontal Cartoning Machine Works

- Picks carton blanks from the magazine.

- Erects them using vacuum or mechanical arms.

- Places the open cartons onto a conveyor and moves them horizontally along the line.

- Feeds and synchronizes products with the moving cartons.

- Pushes each product sideways into its corresponding carton.

- Folds and closes the flaps with tuck-in or glue sealing.

- Discharges the sealed cartons to the next stage of production.

How a Vertical Cartoning Machine Works

- Takes flat blanks from the carton magazine.

- Erects them vertically.

- Holds the open cartons in place on the starwheel.

- Folds and closes the bottom flaps.

- Drops products from above into each carton.

- Seals the top flaps using tuck-in or adhesive sealing methods.

- Discharges the filled and closed cartons to the next stage of packaging.

Cartoning Machine Parts

A cartoning machine is made up of precisely engineered components. These parts work as one to pack products into boxes efficiently. Horizontal and vertical models share many core parts. However, their layouts differ. Learning their unique parts helps you better understand the machine.

Main Components of Horizontal Cartoners

- Carton Magazine: Holds flat carton blanks. Designed for easy reloading and continuous feeding.

- Vacuum Pick-Up and Erecting System: Features suction cups and mechanical arms. Picks each blank and erects it into an open carton shape horizontally.

- Cleated Conveyor: Spaces out the cartons. Transfers and synchronizes them with the product infeed.

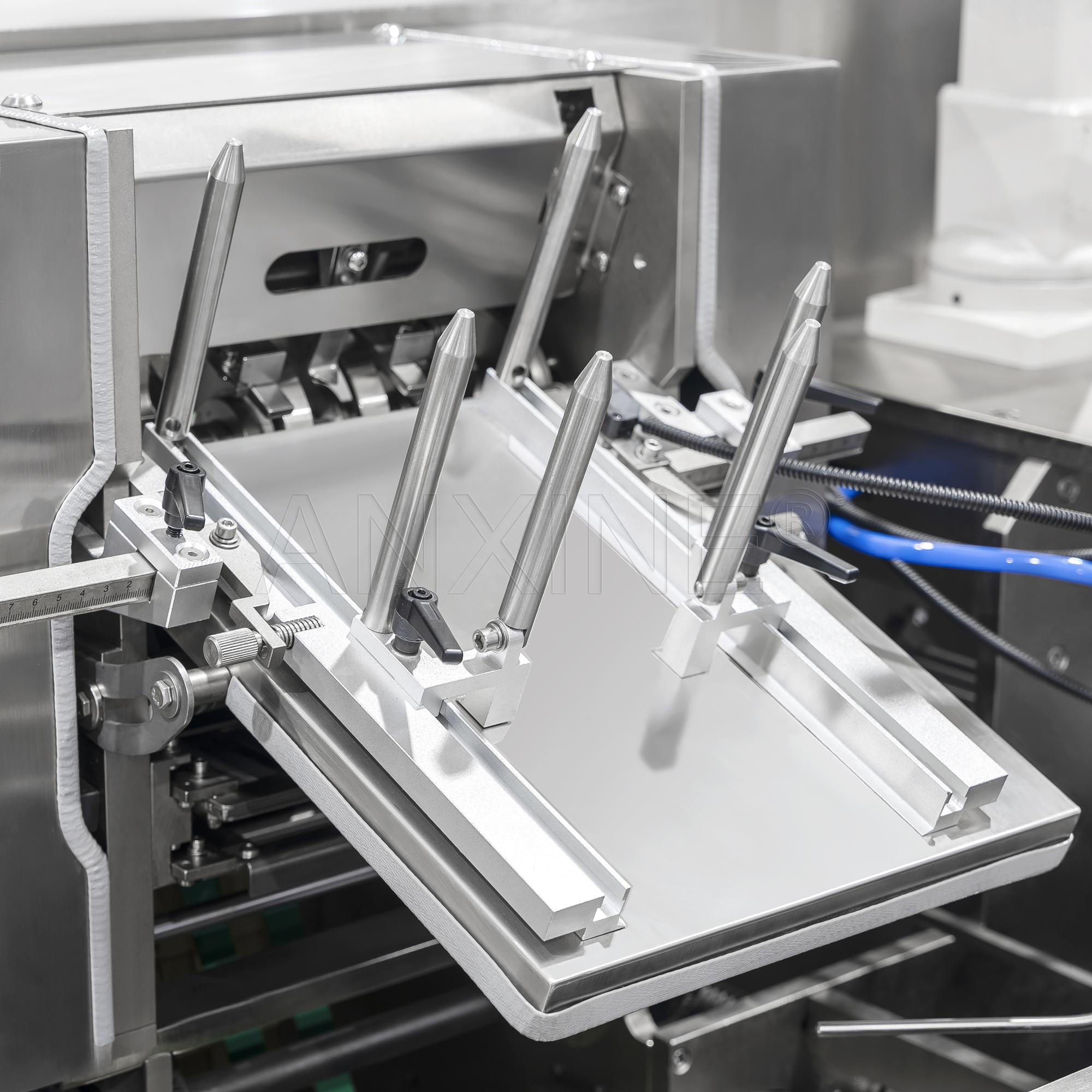

- Pusher or Inserter: Pushes the product horizontally into the open carton.

- Sealing Station: Closes cartons by tuck-in or gluing flaps.

Key Parts of Vertical Cartoners

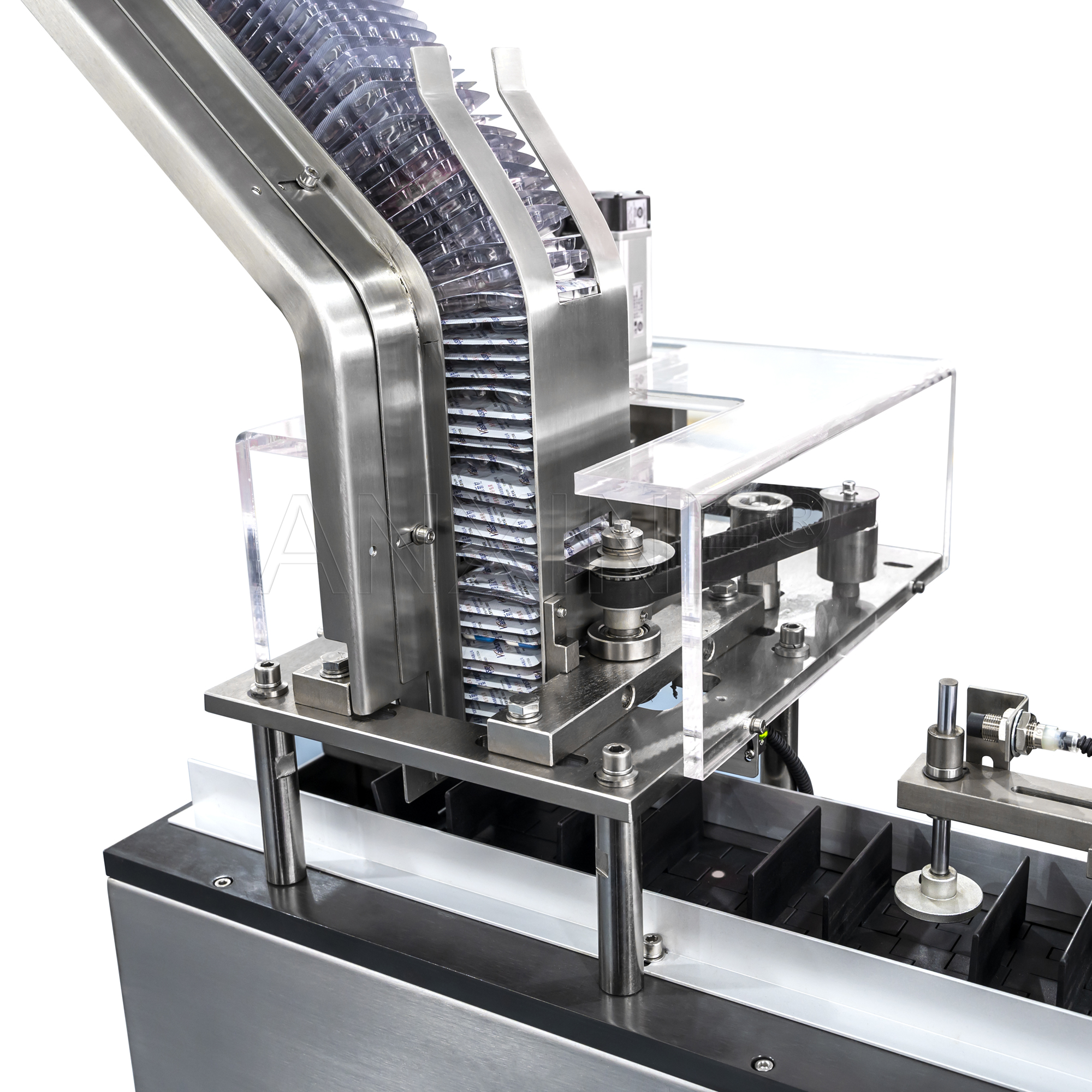

- Carton Magazine: Store flat blanks. Arranged for vertical feeding.

- Vertical Erecting System: Like horizontal models, uses vacuum suction. Form a blank into a carton standing upright.

- Starwheel Conveyor: Holds cartons securely. Indexes them through each station.

- Top Loading System: Features pick-and-place grippers. Drops products from above into the open cartons.

- Flap Folding and Sealing Unit: Folds the top and bottom flaps and locks them by tuck-in or adhesive.

Applications of Cartoning Machines

Carton packing machines bring products safe, organized, and branded secondary packaging. They work in many industries and handle a wide range of products.

Pharmaceutical and Healthcare: Medicines and supplements require secure packaging to ensure patient safety and regulatory compliance. Cartoners pack blister packs, bottles, vials, and medical devices. Many include options for inserting leaflets and applying tamper-evident seals.

Food and Beverage: Food must stay fresh. Today, they also need to be appealing on store shelves. Cartons are easy to showcase, stack, and protect freshness. Companies use the machine to package cereals, snack bars, frozen meals, and dairy items. Carton machines also handle tea bags, coffee pods, and single-serve condiments.

Cosmetics and Personal Care: Beauty products always rely on eye-catching packaging. Cartons offer a custom and premium presentation. Many machines can create windows on the surface of cartons to improve shelf appeal.

Household and Consumer Goods: Everyday items also benefit from cartons. The packaging makes them safer to ship and easier to stock. Examples include soap bars, tissues, detergent packets, batteries, and small electronics.

Why Choose Anxine Cartoning Machines?

Anxine offers a complete cartoning range, from compact vertical models to high-speed horizontal units. You can find standalones and advanced options that fit easily into your current packaging setup.

- Wide product selection covering end-load and top-load cartoners

- Fast and reliable carton forming, filling, and closing

- Stainless-steel contact parts with hygienic, easy-clean design

- Quick changeovers and simple controls that reduce downtime

- Flexible options for tuck-in or glue sealing, leaflet insertion, and coding

- Compact layouts with smooth operation and low maintenance needs