What is a Labeling Machine?

A labeling machine, also known as a label applicator, is engineered to apply labels to products or containers. The labels are often made from paper or metal foil. Most advanced models also integrate code printing systems. That means, in addition to labeling, these machines let you add more product information to each label—for instance, batch numbers, expiry dates, and barcodes.

Labeling is now essential in modern packaging processes. No matter the industry you’re in, pharmaceuticals, food, beverages, or cosmetics, a piece of labeling equipment brings you enhanced product recognition, higher packaging efficiency, and guaranteed compliance.

What are the Common Types of Labeling Machines?

Labeling machines on today’s market can be grouped in many ways. For most buyers, three standards are the most practical: how automated the system is, how it applies the label, and where the label goes. Understanding them makes it easier to find the right equipment for your packaging line. Let’s take a closer look.

By Automation Level

This is the most straightforward way to differentiate the types of label applicators. The degree of automation decides how much labor is needed, how fast you can run, and how much you should invest.

Manual Label Applicator

These units are simple tools operated by hand. No electrical powder is required. They perform labeling using just a group of rollers and a hand crank. They are low-cost and compact, but limited in speed and packaging type—often work with cylindrical containers. Manual labelers are suitable for home-based businesses where labeling a few dozen items per day is enough.

Semi-automatic Labeling Machine

Semi-automatic machines automatically dispense and apply labels, but still require human input. For example, the operator needs to load the product in place. These label applicators usually come in a tabletop model with a foot pedal for labeling control. They’re more accurate and efficient than manual models, as well as more affordable than a fully automatic labeler. If you’re a startup or upgrading your home business, this type of labeling machine is a solid choice.

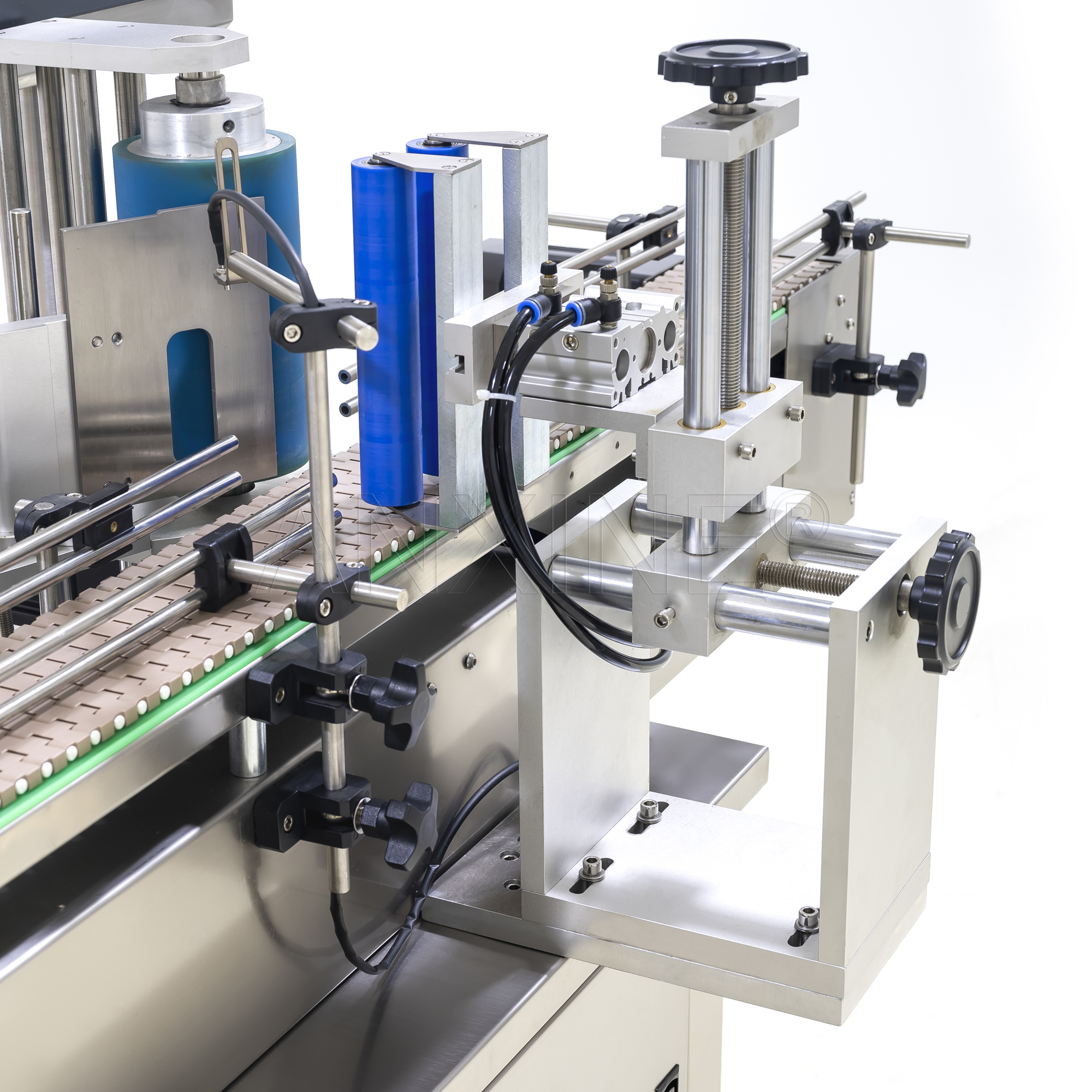

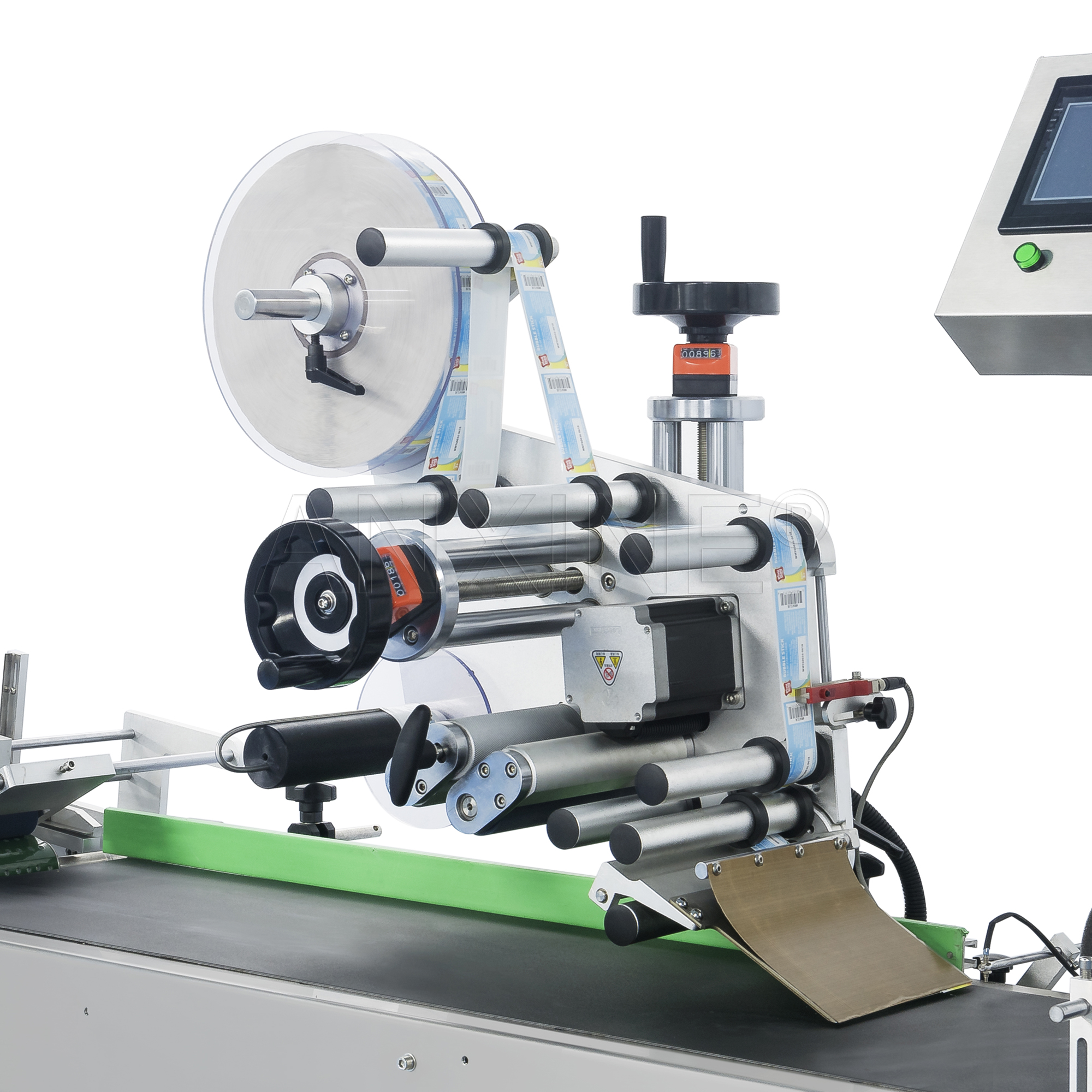

Fully Automatic Labeling Machine

These systems are more complex. They have conveyors, sensors, applicators, and even code printers. These machines can run continuously and apply hundreds of labels per minute, not to mention the precision. This makes them a standard in mid-sized and large-scale production. Additionally, these labeling machines are designed to integrate seamlessly with existing packaging lines.

By Application Method

Most semi-automatic and fully automatic labeling machines are flexible for product shape or size, but they typically boast a specific way to apply self-adhesive labels. So, when you look out in the market, you will probably come across the following types:

Wipe-on Label Applicator

This machine works by the simplest label application method. It uses a brush or roller to “wipe” a label onto the flat surface of a product. The labeling speed is matched to the conveyor to ensure a bubble-free result. This type of labeling machine works best for packaging with a flat or smooth surface.

Tamp Label Applicator

This is a pneumatic-operated labeler. It relies on a pad to press the label onto flat or semi-flat surfaces under a controlled force. Thanks to the vacuum pad, this machine can apply labels to hard-to-reach areas, like a recessed spot. However, it’s slower than the wipe-on method because the product must stay still during labeling.

Blow-on Label Applicator

The blow-on or air-blow method relies on a controlled jet of air to apply labels. It uses a vacuum pad to grab the label and then blows it onto the container or packaging as set. Notably, the applicator has no direct contact with the surface of the product. This labeling machine is ideal for labeling delicate or irregularly shaped products.

By Labeling Position

Due to functional, aesthetic, and regulatory requirements, product labels are placed in different positions. Specific labeling machines have therefore been built to serve the purpose. They are:

Side Labeling Machine

These machines attach labels precisely to the sides of containers. During the process, these containers typically stand upright as they move down a conveyor. These label applicators often use the wipe-on, tamp, or air-blow method. They can be adjusted to accommodate product profiles like round bottles and square cartons.

Top & Bottom Labeling Machine

This machine is configured with two labeling heads. One is positioned above the product. This head wipes, tamps, or blows a label onto the top of the product as it moves along a conveyor. The other head sits in a gap of the conveyor to do its job. The machine applies two labels in a single pass. It’s especially useful for flat-sided items like boxes, trays, and other flat containers.

Wrap-around Labeling Machine

This automated system uses the wipe-on method. It applies labels that wrap fully or partially around the circumference of round containers. It features belts or vertical rollers to press a label onto the container. Wrap-around labeling is considered a cost-effective alternative to shrink wrapping.

Benefits of Using Automatic Labeling Machines

One of the biggest benefits is efficiency. For example, a beverage plant fills and caps hundreds of bottles per minute. An automatic wrap-around labeler can keep pace with the upstream processing to ensure the desired output is achieved.

They also deliver accuracy. In pharmaceuticals, automatic labelers place pill bottle stickers in the exact same spot every time. This ensures compliance with strict regulatory demands.

Automatic labeling machines also improve traceability. Integrated code printers add batch numbers or “Best By” dates when labeling food items. These producers rely on this to manage recalls if needed.

Finally, they bring cost savings. By cutting labor and reducing label waste, companies see lower operating costs. For example, nutraceutical firms running multiple SKUs on one line avoid relabeling errors.

Why Choose Anxine Labeling & Code Printing Machines?

Whether you’re looking for entry-level tabletop units or fully automatic systems, we have you covered. At Anxine, we offer a wide portfolio of labeling and code printing solutions to take care of products of any shape and size. Every machine is well-crafted for precise label application and long-term durability.

- Broad lineup covering side, top & bottom, and wrap-around labeling solutions

- Semi-automatic and fully automatic models equipped with code printing options

- Features electric-eye sensors to ensure accurate label placement

- Stainless-steel construction and GMP-compliant design

- Intuitive controls and quick changeovers to support multi-SKU production

- Allows smooth integration with existing packaging lines for continuous operation