What is a Pouch Filling and Sealing Machine?

In most cases, a pouch filling and sealing machine operates automatically. It’s designed to package products into flexible pouches. Depending on the configuration, it can form pouches from film rolls, fill them with product, and seal them, or it can work with ready-made pouches for filling and sealing only. This kind of equipment delivers consistent, airtight packaging for solids, powders, liquids, or granules, not to mention a wide range of pouches. That’s why pouch filling and sealing machines are a hit in food, pharmaceutical, chemical, and agricultural industries.

Types of Pouch Filling and Sealing Machines

As we touched on earlier, pouch filling and sealing machines may have several configurations. That means they come in different types. Here are some common types on the market.

Form-Fill-Seal (FFS) Machines

These pouch filling machines form the pouch from roll stock film, fill the pouch with product, and then seal it. All actions are in one continuous cycle. FFS units can also be divided into two main layouts:

- Vertical (VFFS): The vertical form fill seal machine is space-saving and works well with powders, granules, and free-flowing materials.

- Horizontal (HFFS): Horizontal units run faster and are ideal for shaped pouches or pouches with special features like spouts.

Premade Pouch Packaging Machines

These machines are totally different from the FFS machine. They can’t make bags themselves. The premade pouch filling machine is engineered to handle ready-made pouches. They typically feature multiple working stations to pick up each pouch, open it, fill it with the product, and seal it shut. Most models offer quick changeovers, making them flexible with pouch sizes and styles.

Continuous Band Sealers

Band sealers are also a popular choice in pouch packaging. Unlike the previous two, they are seal-only machines for pre-filled pouches. They use heat and pressure to form a neat, airtight seal on the pouch. A continuous band sealing machine often comes in a compact tabletop design. They’re affordable and widely used for small operations. Since featuring a conveyor belt, they also serve as a sealing stage in a production line.

Pouch Filling and Sealing Machine Working Principle

Now that you know the main types of pouch filling and packing machines, it helps to understand how each one actually works. Here’s a look at the working principle of each type.

How Form-Fill-Seal (FFS) Machines Operate

These pouch sealing machines work by feeding a roll of packaging film into the system. The film is unwound and shaped into a pouch around a forming tube. One side of the pouch is sealed, product is dispensed through the tube, then the top is sealed and trimmed. Vertical FFS machines drop product from above; horizontal models feed and seal pouches in a horizontal layout.

How Premade Pouch Machines Handle Filling and Sealing

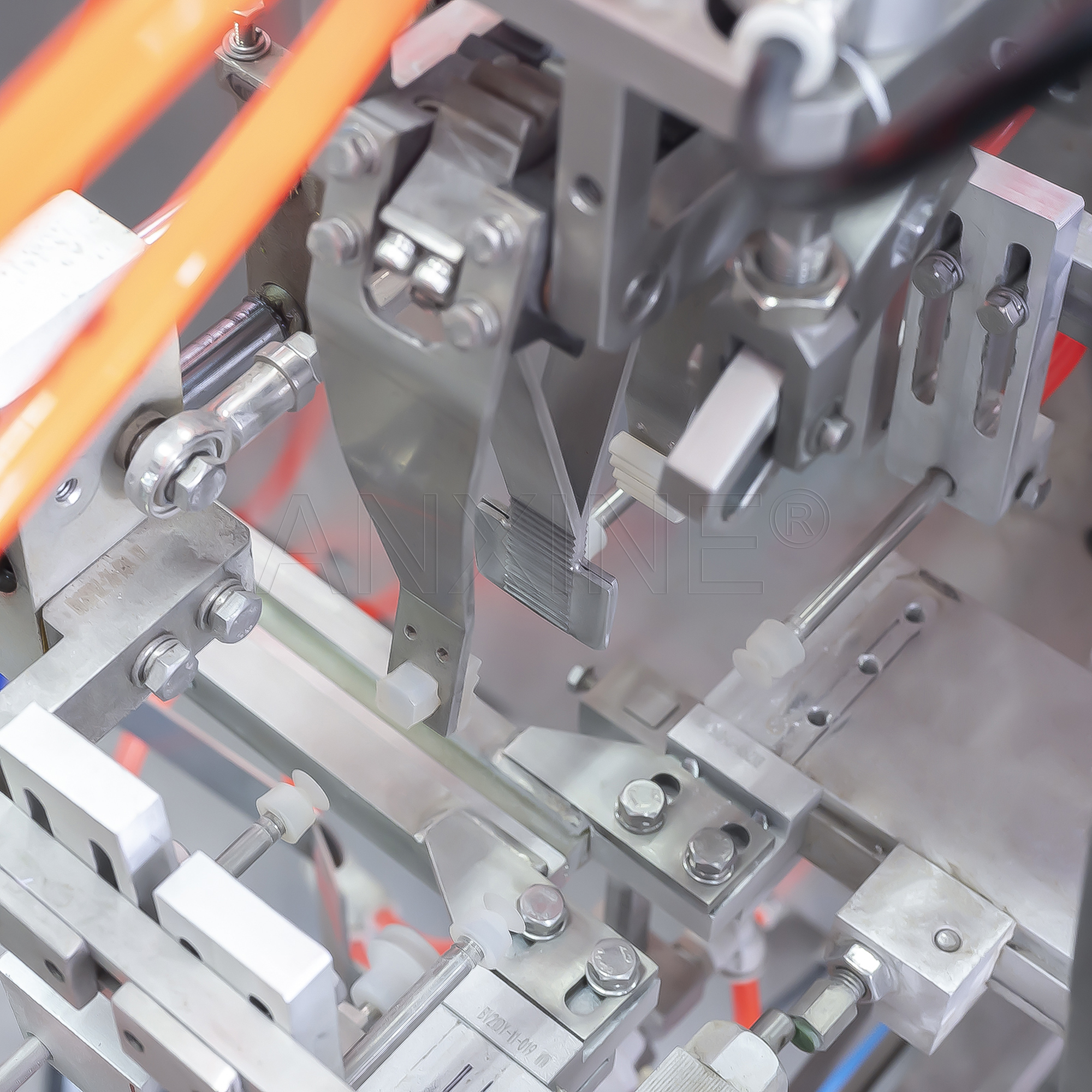

These systems use ready-made bags instead of forming them from film. Mechanical grippers pick up each pouch, open it with suction or air, and hold it steady for filling. Once filled, the machine uses heat sealing jaws to close the top, then discharges the finished pouch.

How Continuous Band Sealers Close Filled Pouches

Band sealers work on pouches that have already been filled. The filled bags move along a conveyor and pass between heated sealing belts. The belts apply controlled heat and pressure to create a consistent seal, followed by cooling to flatten and strengthen it.

Applications of Pouch Filling and Sealing Machines

So, how do these pouch filling and packing machines fit in real-world production? Let’s explore the typical applications for each type and see where they deliver the most value.

| Machine Type | Key Applications & Product Examples |

| Vertical Form-Fill-Seal (VFFS) | High-speed food and pharma packaging;Ideal for bulk goods like nuts, cookies, grains, powders, liquids (ketchup, sauces, bath gels);Common for snacks, frozen foods;Vertical filling reduces contamination risk. |

| Horizontal Form-Fill-Seal (HFFS) | Suited for solid or fragile items placed horizontally;Used for confectionery, single-serve condiments, medical devices;Handles pre-made pouches with zippers or spouts for better convenience and appearance. |

| Premade Pouch Filling Machines | Fill and seal ready-made pouches (doypacks, zipper, spouted, custom shapes);Package powders (spices, pharma), liquids (beverages, sauces, oils), pastes, gels;Ensure hygienic filling, airtight seals;Used in pet food, food, and pharmaceuticals. |

| Continuous Band Sealers | Seal pre-filled pouches at high speed;Used for snacks, coffee, spices, medicines, fertilizers, industrial powders, pet food, seeds;Produce strong, consistent seals for thermoplastic or barrier bags. |

Why Choose Anxine Pouch Filling & Sealing Machines?

Anxine has built a full lineup to meet nearly every pouch packaging need. The range includes compact band sealers, high-speed form-fill-seal systems, and flexible premade pouch machines. Each pouch filling and sealing machine is designed for reliable performance, hygienic operation, and easy integration into your line.

- Consistent filling and sealing quality for different pouch formats and products

- Wide product range covering form-fill-seal, premade pouch, and seal-only equipment

- Stainless steel contact parts and smooth finishes for hygienic, GMP-ready design

- Quick changeovers and simple controls to reduce downtime

- Compact layouts with high output to save space and operating costs

- Accurate handling of powders, liquids, pastes, and solid products