What is a Blister Packaging Machine?

This blister packing machine is used to pack tablets and capsules within individual cavities. The back would be sealed with a backboard. This design protects medicines from moisture, light, and contamination. Also, it makes the medicine easy to carry and use. Each cavity holds a single dose, so patients can use the medicine more safely and conveniently. Good blister packaging keeps product quality stable and safe during storage and transport.

Now blister packaging is a popular packing type for tablets or capsules. It is widely used in industries such as pharmaceuticals, food, and consumer goods. So a blister packing machine is a must for your pharma or supplement business.

Benefits of Blister Packaging Machine

A blister packing machine greatly improves production efficiency. It can run at high speed and handle large volumes for mass production. It ensures consistent cavity forming and accurate product placement.

Applications of Blister Packaging Machine

Blister packaging equipment has many uses in different industries. Here are some examples.

- The pharmaceutical industry. It is used to pack tablets, capsules, and lozenges.

- The nutraceutical industry. This is applied for vitamins, dietary supplements, and herbal products.

- The food industry. The machine is commonly used for candies, chewing gum, mints, and small snacks. Blister packs help maintain freshness and allow attractive product display.

Types of Blister Packaging Equipment

Desktop Blister Packing Machine

They are compact models designed to sit on a table. They are smaller than industrial machines but still provide reliable blister sealing for different products. The small blister pack machine is often manual or semi-automatic. So the operator loads products by hand and then uses the machine to form and seal the packs.

Because of their size, they are ideal for laboratories, pharmacies and hospitals. It is also ideal for small businesses that need limited production runs or trial batches. Desktop blister machines feature easy operation, good price, and space-saving.

Fully Automatic Blister Packaging Machine

The automatic blister packing machine could handle all steps by itself throughout the whole process. It includes cavity forming, product loading, sealing, and sometimes inspection. They are designed for large-scale and high-speed production in pharmaceutical or nutraceutical industries. These machines offer consistent quality and reduce labor costs. Moreover, fully automatic models feature defect detection, easy format changeover, and seamless integration with other packaging lines.

Rotary Blister Packaging Equipment

Rotary blister machines are high-speed equipment designed for large-scale production. They use a rotating drum. It makes blister cavities continuously formed, filled with tablets, and sealed in a circular motion. This design allows the machine to handle multiple rows of products at the same time. It reduces much energy and production time.

Rotary blister packing machines are fully automatic, often equipped with sensitive controls and inspection systems. So they are suitable for companies that need efficiency, consistency, and high productivity in packaging.

What is the Main Blister Packaging Process?

Take a fully automatic blister packing machine for example. At first, it feeds a roll of plastic film, usually PVC, into the machine. The film is heated and then shaped into cavities. Once the cavities are ready, tablets or capsules are automatically placed into each pocket by the feeding system.

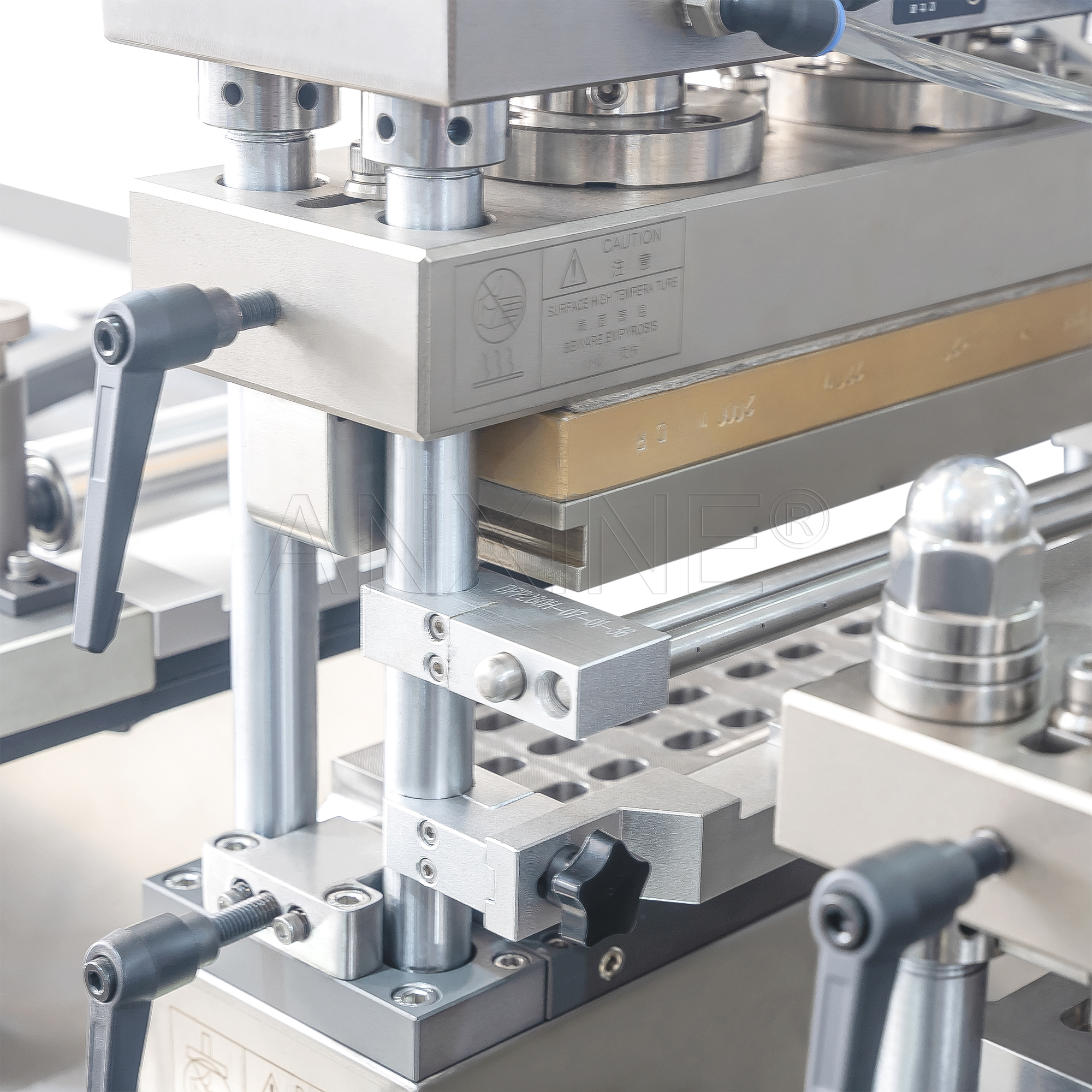

After filling, a sealing material, most often aluminum foil, is placed over the cavities. Next, it is tightly sealed with heat and pressure. The sealed strip then moves to the cutting station. It would be cut into individual blister packs of the required size and layout. At the end, inspection systems may check if there are any missing products or sealing defects. When everything is ok, the finished products are sent for cartoning or further packaging.

Common Blister Packaging Material

There are various materials used to make blisters and backboards. Here are some popular ones for your reference.

PVC

Rigid PVC film is the most common material in blister packaging. It features a clear appearance, easy processing, and low cost. This makes it attractive and effective for mass production. Its good transparency allows patients and consumers to see the product inside, which helps with product identification and trust.

However, PVC doesn’t have good barrier properties against moisture and oxygen. So it is not suitable for drugs that are highly sensitive to environmental conditions. For this reason, it is mostly used for standard tablets and capsules that do not require strong protection.

PVDC-coated PVC

PVDC-coated PVC combines a PVC base with a thin layer of PVDC to improve protection. The coating greatly increases the barrier against moisture, oxygen, and aromas. This makes it a popular choice when a longer shelf life and higher stability are required.

However, PVDC-coated PVC is more expensive than normal PVC. It also requires more complex processing for use.

Aluminum foil

Cold-form aluminum foil is another common material. It is especially useful for medicines that are very sensitive to light and moisture. This method forms cavities by pressing the foil without heat. It creates a 100% barrier against environmental factors.

But the disadvantage is that the packs are opaque, so the product inside cannot be seen. Cold form foil is also more expensive and it runs slower on machines compared to plastic-based materials.

Why Choose Anxine Blister Packaging Machine?

As a leading manufacturer of industrial equipment in China, Anxine offers

Various Machine Types for Blister Packaging

There is a wide range of blister packaging equipment for you to choose from. It includes different models from desktop to fully automatic ones. You just tell us your required production volume, budget and other demands. Then we’ll select the most suitable machine quickly to meet your needs. Our technical team is always ready to solve your problems.

Flexible Customization

If you need some change for more functions or efficiency, we also support customization. Take the forming system for example. It can be adjusted with heating methods, mold sizes, and cavity shapes to match various products or unique designs. We’ll discuss with you every detail to ensure the quality and efficiency. Also, we’ll connect you in real time with photos or videos. Then you can check the customization process by yourself and see if it meets your requirements. If you have any problems during the process, contact us at any time.