Automatic Dropper Bottle Filling & Cap Screwing Machine CGS-1

Fast Dropper Bottle Filling and Cap Screwing Machine CGS-1

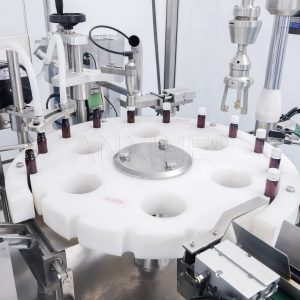

The CGS-1 automatic model is made for filling and capping small dropper bottles. It can fill liquids like eye drops, oils, or other products. It uses a peristaltic pump, which gently moves the liquid through a soft tube and into the bottle. The machine picks up each cap and tightens it automatically. Sensors check for missing bottles or caps so nothing is wasted. The whole system is clean, safe, and easy to use. It’s a good fit for small bottle production in medicine, skincare, or lab use.

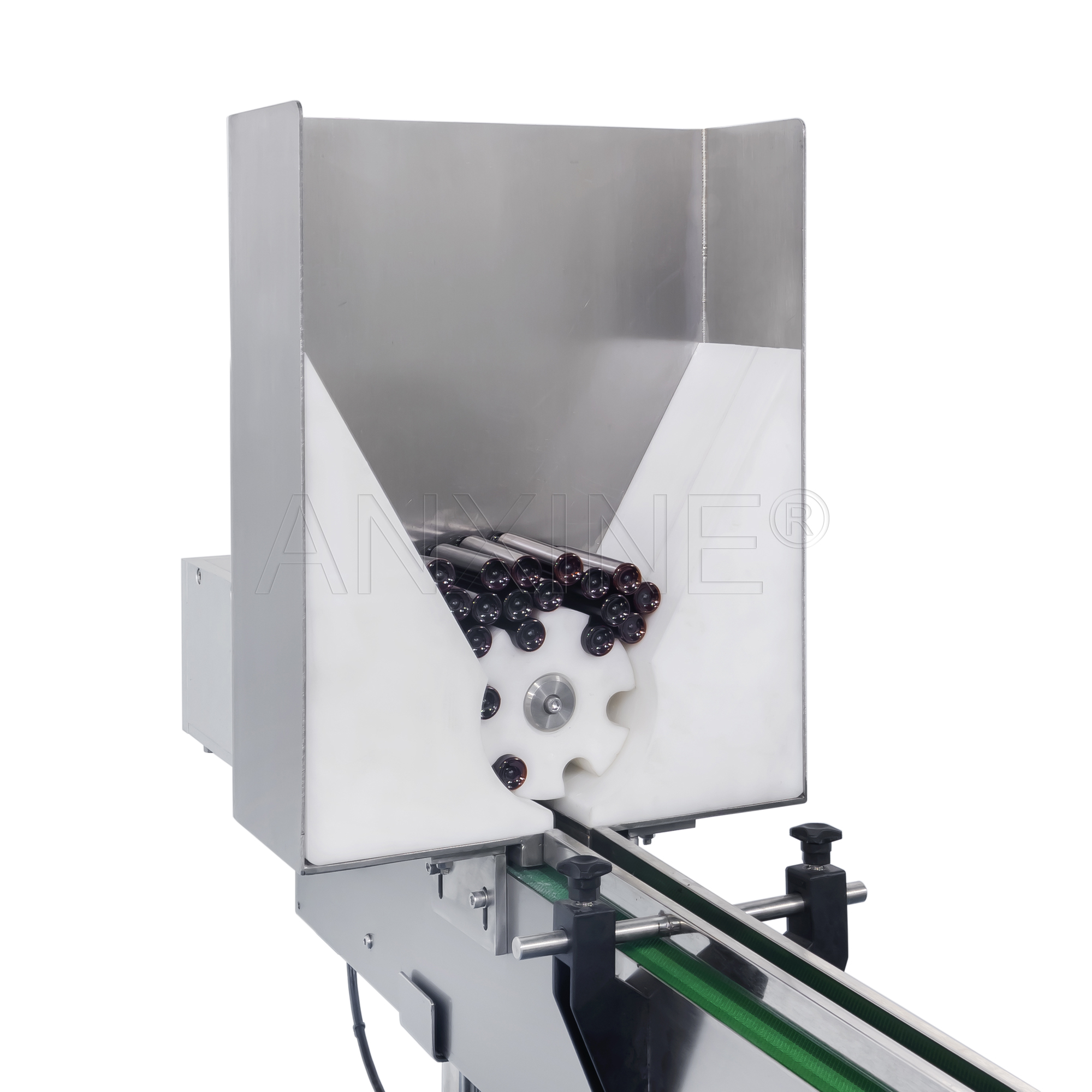

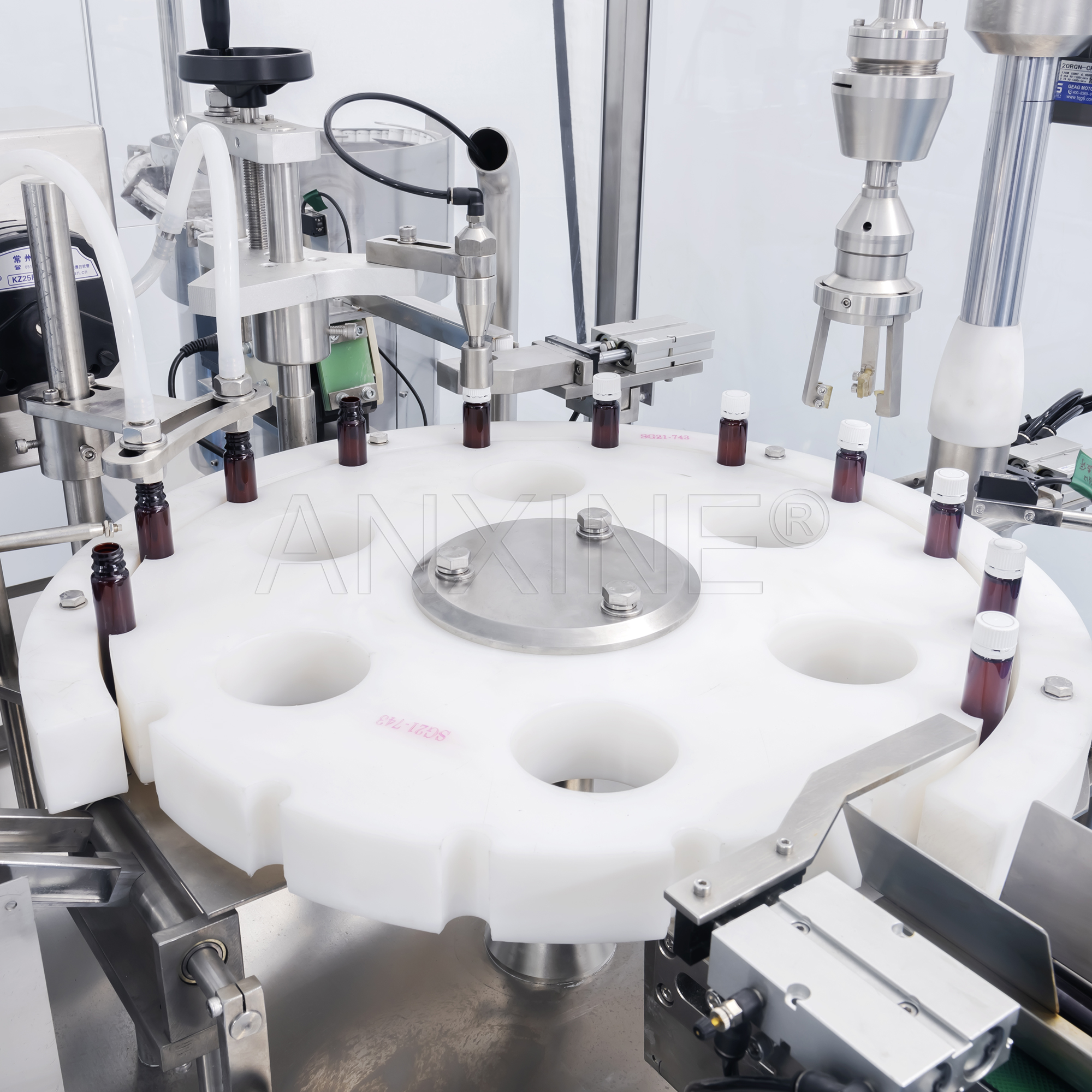

During operation, the machine starts by organizing empty bottles and turning them upright. It moves the bottles into place one by one with a rotating platform. The peristaltic pump fills each bottle with a set amount of liquid. This pump can work accurately for small doses. If the machine sees that a bottle is missing, it will skip the filling step to avoid spills. The bottles then go to the capping station. Next, the caps are gently pressed and screwed on tight. Finally, complete products are sent for further processing.

Description

Everything in this machine is built for accuracy and safety. The CGS-1 can fill around 1,500 to 1,800 bottles each hour.

Highlighted Features

- Precise filling system. The machine uses a peristaltic pump that delivers exact amounts of liquid, ideal for small doses.

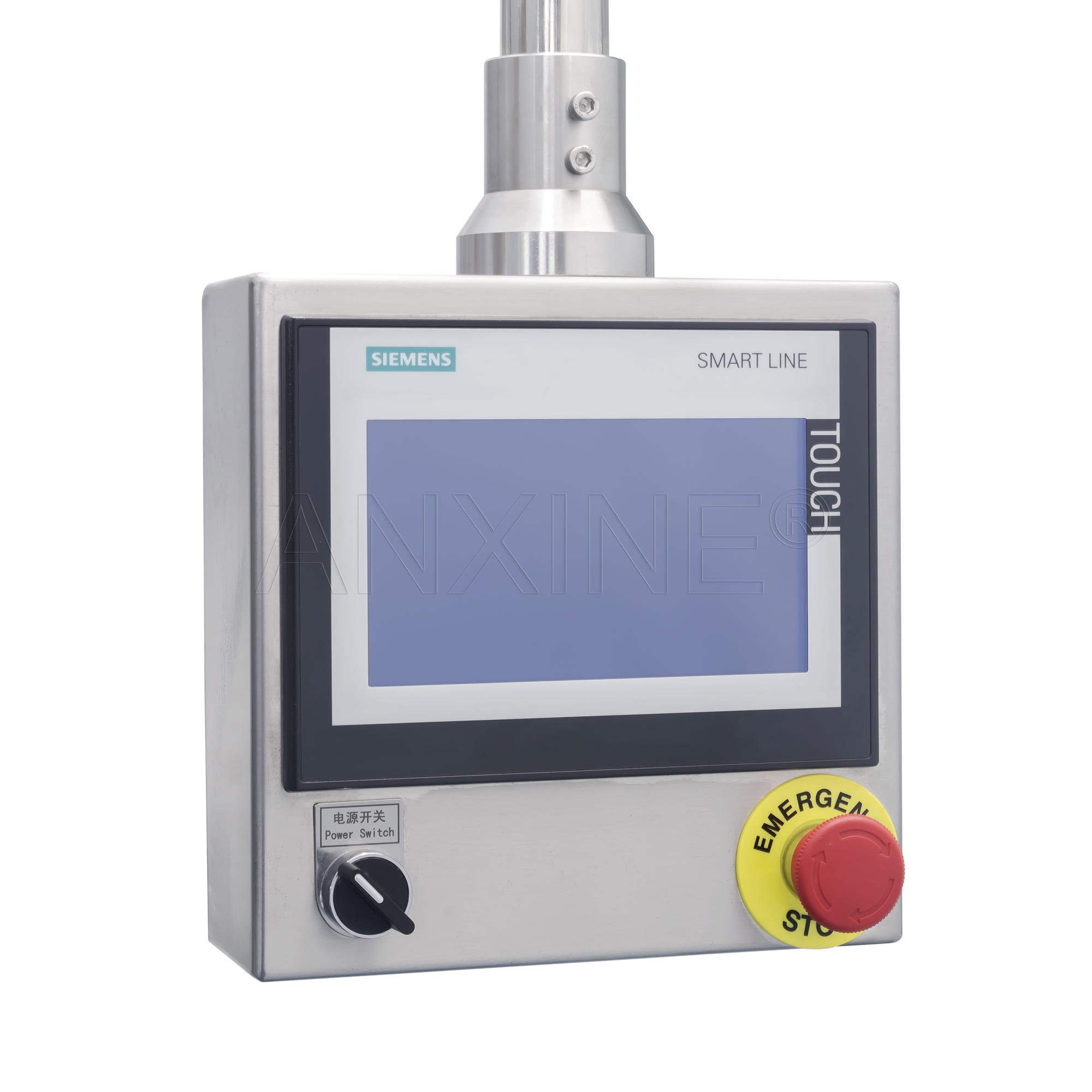

- Smart sensors. Sensors check if a bottle or cap is missing. If so, the machine stops that step to avoid mistakes.

- Adjustable for different bottles. The filling needle height and position can be changed to match the bottle size.

- Stable operation. It runs smoothly with the help of air pressure and has safety systems to protect the parts.

- Easy to maintain. The machine includes simple access to key parts, and regular maintenance is easy to follow.

- Production line integrated. It can work alone or connect to other machines for full packaging automation.

Specifications

| Model | CGS-1 |

|---|---|

| Production Capacity | 1500-1800 bottles/hour |

| Air Pressure | 0.5-0.8 MPa |

| Air Volume | 25-27 m³/h |

| Power Supply | 220V 50Hz |

| Total Power | 2 kW |

| Weight | Approximately 800 kg |

| Dimension | 3,500 mm × 2,850 mm × 1,750 mm |

Why Choose Anxine

No Anxiety Needed

With Anxine Machinery, rest assured that you are working with a reliable partner committed to meeting all your machinery and production needs efficiently and effectively.

Exceptional Service

Benefit from our exceptional customer service that includes a 1-year warranty and lifetime support, ensuring your equipment remains in optimal condition for years to come.

Quality Assurance

Our products undergo strict quality control measures to ensure reliability and performance. Anxine Machinery is ISO9001 certified and meets GMP and CE standards, reflecting our commitment to excellence.

Innovative R&D

Our research and development team comprises industry experts and technical professionals who continuously drive product innovation and technological advancements, keeping us at the forefront of the pharmaceutical machinery industry.

Global Support

With a robust global network, Anxine Machinery’s products are exported to over 200 countries and regions. We offer 24/7 support to meet client demands and ensure seamless operation worldwide.

Custom Solutions

We understand that every client has unique requirements. Our team excels in providing highly customized solutions tailored to your specific needs, enhancing your production processes.

Also Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Our offerings include state-of-the-art equipment for capsule filling and blister packing, supported by expert custom solutions and a robust global service network.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288

Daohang Rd. Ruian, ZJ, P.R.C.