Uphill Elevating Capsule Polisher and Sorter ACP-100V

ACP-100V Elevated Capsule Polisher & Sorter

Our ACP-100V helps you make a steady, continuous flow of pharmaceutical products. This capsule polisher and sorter works on three different tasks. First, it gently but effectively removes all dust and static from your capsules. Second, it automatically sorts out any defective capsules, like ones that are empty or broken. Third, it lifts the capsules to the perfect height for your next machine, whether it’s a blister packer or bottle filler. It does all this automatically. This makes sure that only perfect, high-quality capsules reach the final packaging stage.

Description

The ACP-100V capsule polisher is a very versatile machine. It cleans and elevates your capsules. It connects easily to your capsule filling machines, sorters, and metal detectors. This makes sure that capsules are perfectly processed from start to finish. Any defects in the capsules will be caught during production.

Highlighted Features

- Polishing & Elevating: Get both capsule polishing and vertical elevation in one unit, adding great flexibility to your production.

- Seamless Integration: It connects easily with capsule fillers and plays well with existing sorters and metal detectors in your line.

- High Throughput: This machine can handle a massive 600,000 capsules per hour, keeping your production flowing fast.

- Smart Defect Sorting: Automatically removes those imperfect capsules – think under-dosed, empty, fractured, or those with separated caps and bodies.

- Flexible Setup: Both the inlet and outlet can adjust a full 360 degrees, making it easy to fit into any layout.

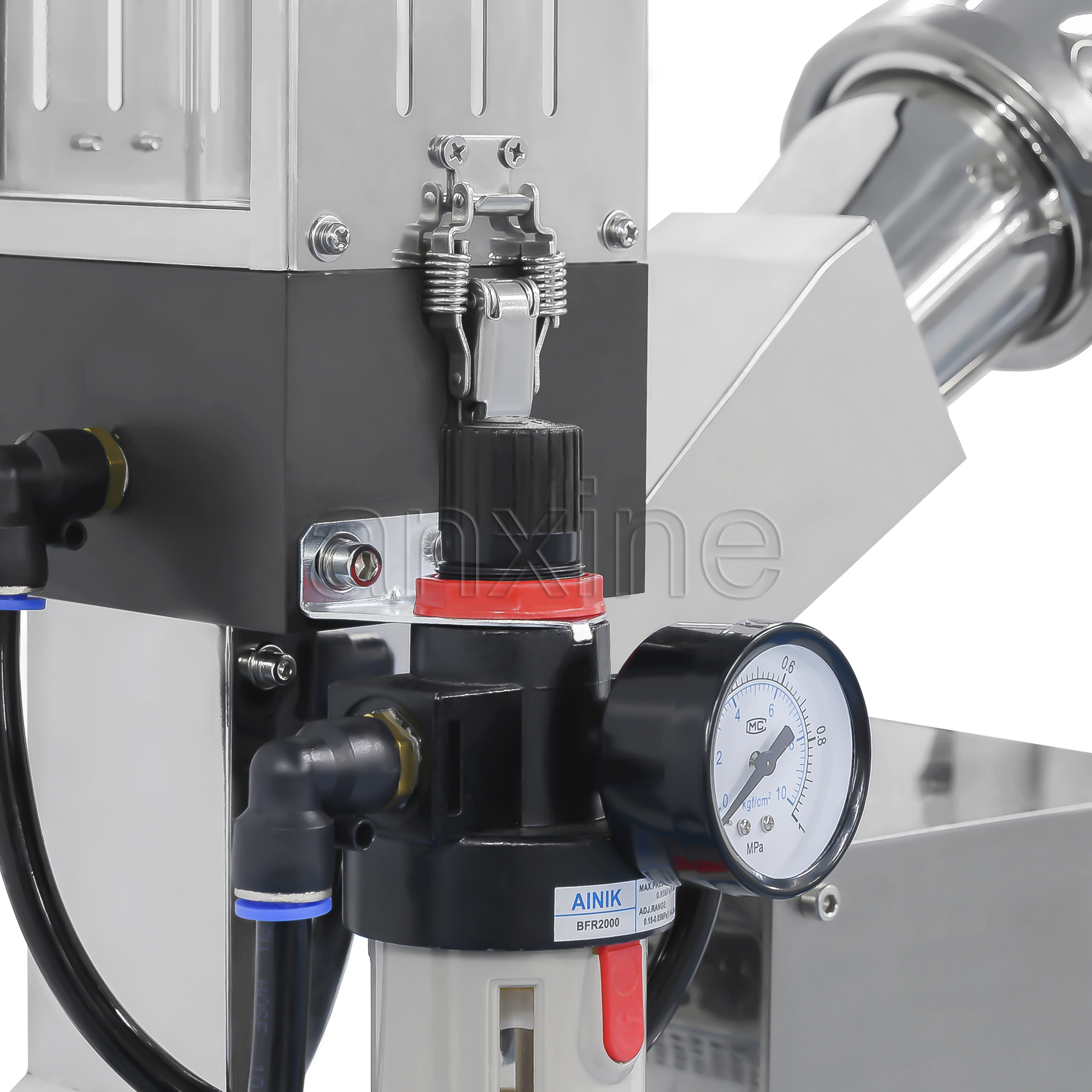

- Quick & Thorough Cleaning: Its fast-joint system means quick disassembly for cleaning, and the main shaft’s detachable brush ensures no missed spots.

- Built for Pharma: All parts that touch your capsules are made from 316L stainless steel, meeting the highest modern medicinal safety standards.

- cGMP Compliant: Designed and built to fully meet strict cGMP requirements.

Specifications

| Model | ACP-100V |

|---|---|

| Application | Suitable for polishing and sorting all capsule types. |

| Max Output | 600,000 pcs/h |

| Capsule Sizes | Compatible with sizes 00#, 0#, 1#, 2#, 3#, 4# |

| Working Voltage | 220V/110V, 50/60Hz |

| Inlet Height/Dimension | Height 800mm, Dimension 300*250mm |

| Outlet Height/Dimension | Height 1040mm, Dimension 65*50mm |

| Overall Dimensions | Length: 500mm Width: 841mm Height: 1,458mm Weight: 80kg |

Why Choose Anxine

No Anxiety Needed

With Anxine Machinery, rest assured that you are working with a reliable partner committed to meeting all your machinery and production needs efficiently and effectively.

Exceptional Service

Benefit from our exceptional customer service that includes a 1-year warranty and lifetime support, ensuring your equipment remains in optimal condition for years to come.

Quality Assurance

Our products undergo strict quality control measures to ensure reliability and performance. Anxine Machinery is ISO9001 certified and meets GMP and CE standards, reflecting our commitment to excellence.

Innovative R&D

Our research and development team comprises industry experts and technical professionals who continuously drive product innovation and technological advancements, keeping us at the forefront of the pharmaceutical machinery industry.

Global Support

With a robust global network, Anxine Machinery’s products are exported to over 200 countries and regions. We offer 24/7 support to meet client demands and ensure seamless operation worldwide.

Custom Solutions

We understand that every client has unique requirements. Our team excels in providing highly customized solutions tailored to your specific needs, enhancing your production processes.

We Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Supported by expert custom solutions and a robust global service network.

Capsule Filling Machine

Discover capsule filler machines designed for speed, accuracy, and ease of use in capsule production.

Pill Tablet Press Machine

High-performance compression machines lead to efficient and high-quality tablet production.

Softgel Encapsulation Machine

Softgel capsule making machines are suitable for various capsule sizes, leading to smooth and accurate capsule production in the pharma and nutritional industries.

Gummy Making Machine

Good gummy makers improve your supplement or candy line, ideal for making CBD, vitamins, and fruit gummies in the pharma and confectionery industries.

Industrial Powder Blender

Get smooth and consistent mixtures with our industrial powder mixers—great for pharma, chemical, food and cosmetic use.

Pill Counting Machine

Automate your bottling process with our counting machines. Accurate, reliable, and suitable for pills in all sizes.

Blister Packaging Machine

Blister packaging equipment works well with ALU-PVC and ALU-ALU blisters, suitable for packing tablets, capsules, and softgels. It is always applied in pharmaceutical and supplement production.

Cartoning Machine

We offer China cartoning machines for pharmaceuticals, food, and cosmetics. Our carton machines deliver high performance to meet global packaging needs.

Pouch Filling & Sealing Machine

View our selection of pouch filling and sealing machines made for effective packaging. We provide various solutions for food, pharmaceutical, and other industries with our range of automatic and semi-automated pouch filler machines and pouch sealer machines.

Liquid & Cream Filling Machine

They are used to fill various types of liquids, creams, and viscous products into different containers accurately and efficiently.

Empty Capsules

Stock your line with premium empty capsules—ideal for medicine, supplements, and more—in a full range of sizes and custom options.

TiO₂-Free Capsules

Switch to our TiO₂-free capsules for safer, more reliable protection of your products.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288

Zhejiang, China (GMT+08)