When manufacturing capsules, we may encounter numerous problems. Some of the first questions you’ll face are: What capsule size should we use? How many grams should fit in a capsule?

Capsules may look simple, but behind every one is a careful calculation. This guide will walk you through the capsule size chart, explain how fill weight is calculated, and share some useful tips for capsule filling.

The Relationship Between Capsule Size and Fill Weight

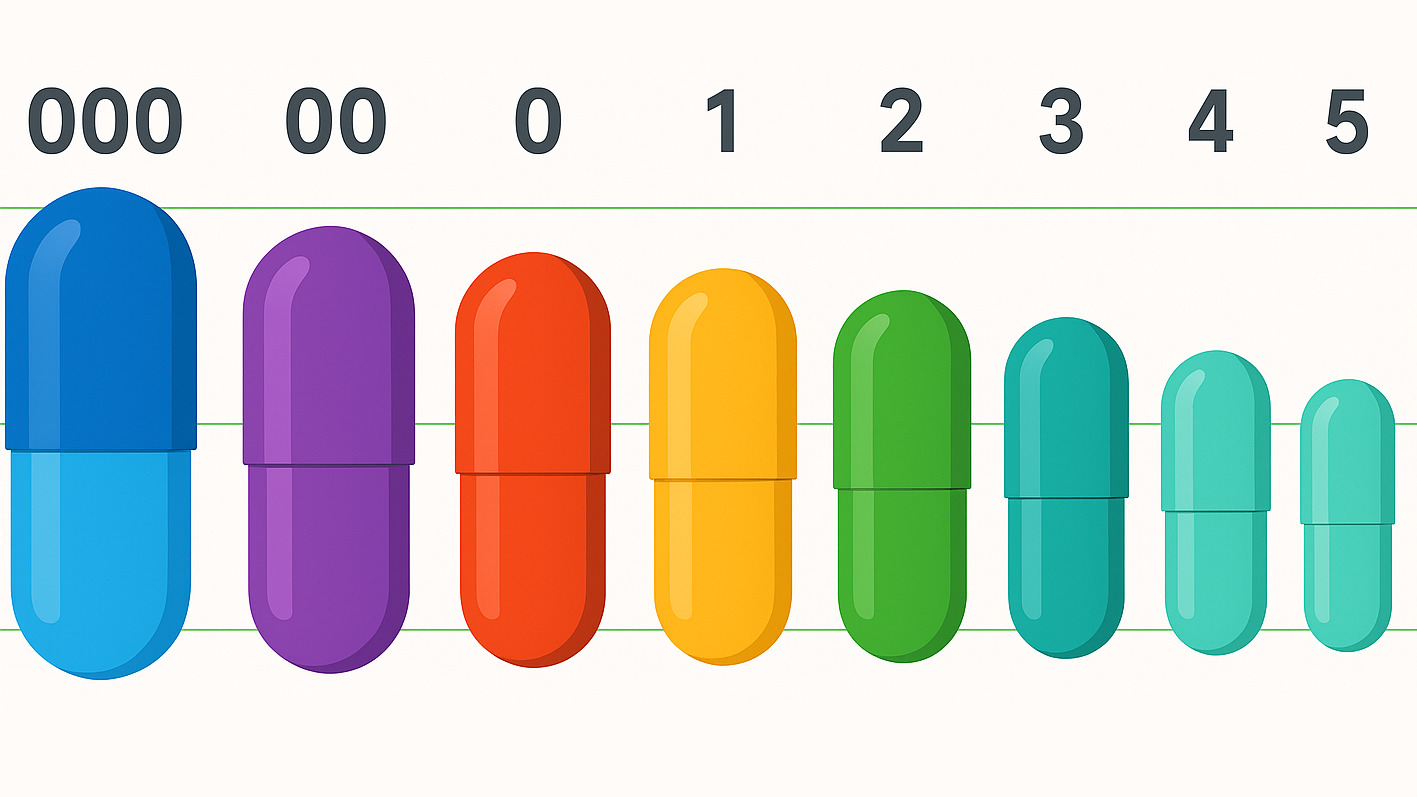

Capsules may seem like they vary at random, but their dimensions actually follow a standard. The size is carefully calculated and usually ranges from 000 to 5. An interesting fact is that the numbering is inverted. That means a smaller number means a bigger capsule.

The fill weight of a capsule refers to how much powder it can hold. This depends primarily on the volume of the capsule and the density of the powder you’re filling it with.

So, capsule size and fill weight are closely linked. Capsule dimensions are standardized by volume—how much space is inside the capsule. The fill weight is how much material that space can hold.

Here’s the key: the capsule size stays the same, but the weight depends on the material to be filled. For example, a fluffy herbal powder might only weigh a few hundred milligrams in a size 0 capsule. A denser vitamin powder could double the fill weight in the exact same capsule.

Each capsule is just like a tiny container:

- Bigger capsule = more room → higher possible fill weight

- Smaller capsule = less room → lower possible fill weight

This is why capsule size charts list volume and then give estimated weights at different powder densities.

| Capsule Size | Volume (ml) | Approx. Fill Weight at 0.6 g/ml (mg) | Approx. Fill Weight at 0.8 g/ml (mg) | Approx. Fill Weight at 1.0 g/ml (mg) | Approx. Fill Weight at 1.2 g/ml (mg) |

| 000 | 1.37 | 822 | 1096 | 1370 | 1644 |

| 00 | 0.90 | 540 | 720 | 900 | 1080 |

| 0 | 0.68 | 408 | 544 | 680 | 816 |

| 1 | 0.48 | 288 | 384 | 480 | 576 |

| 2 | 0.36 | 216 | 288 | 360 | 432 |

| 3 | 0.27 | 162 | 216 | 270 | 324 |

| 4 | 0.20 | 120 | 160 | 200 | 240 |

| 5 | 0.13 | 78 | 104 | 130 | 156 |

💡 What Does “0.6 g/mL / 0.8 g/mL / 1.0 g/mL / 1.2 g/mL” Mean?

- g/mL stands for grams per milliliter, a measure of density.

- If a powder’s density is 0.8 g/mL, 1 mL weighs 0.8 grams (800 mg).

How to Calculate Capsule Fill Weight

Calculating the fill weight of a capsule is simple. You only need to know two things: the capsule volume and the powder density. The formula is:

Fill Weight = Capsule Volume × Powder Density

Say you have a powder with a bulk density of 1.0 g/mL. If you plan to use a size 0 capsule (volume ~ 0.68 mL), the estimated fill weight can be:

0.68 mL × 1.0 g/mL = 0.68 g (about 680 mg per capsule)

Let’s pull up the capsule size chart to verify this. At 1.0 g/mL, a size 0 capsule was listed around 680 mg, which matches our math. Likewise, if you had a very fluffy powder density of 0.6 g/mL, that same capsule would only hold ~408 mg.

Always remember that real-world results can vary. So after calculating, it’s a good idea to fill a few capsules and weigh them to confirm your numbers.

Factors Affecting Capsule Fill Weight

Capsule filling is a science-driven process that demands precision and consistency. One of the primary goals in capsule manufacturing is to achieve a uniform, accurate fill weight every time. But there are many variables that can affect the outcome. Let’s take a look at these factors.

Capsule Size

Capsule dimension is the first and most obvious factor in determining fill weight. Each size has a fixed internal volume. At the same density level, a size 00 capsule can hold more material, and a size 0 holds less. Simply put, the bigger the capsule, the higher the potential fill weight. If you want to meet a desired dose in a single capsule, choosing the correct capsule size is crucial.

Powder Density

Remember the formula we used to calculate the fill weight? Powder density is one of the two key terms. In this context, density simply means how much powder or liquid fits in a given capsule volume (g/mL).

Want to see it in action? Try this simple experiment:

- Take two empty capsules of the same size—call them Capsule A and Capsule B.

- Fill Capsule A with a light, fluffy powder

- Fill Capsule B with a heavy, dense powder.

- Weigh both capsules.

You’ll find that Capsule A weighs less than Capsule B. Why? Because the powder in Capsule B is packed more tightly. It might take two or three fills to completely pack the capsule body. That means more milligrams of powder go inside the shell. But with fluffy powder, the capsule may look full after just one fill.

Moisture Content

Moisture levels in a formulation also affect fill weight. Water adds extra mass. A powder that contains some moisture or oil will weigh more than a completely dry powder of the same volume. If you’re working with a hygroscopic powder, the water content can make each capsule slightly heavier.

Too much moisture can create other problems. It makes the powder clump together. When capsules are filled with more clumped material, this can lead to inconsistent fill weight. Plus, damp powder may not flow freely. Most capsule manufacturing today relies on dosing disc filling. Poorly flowing powders often result in uneven fills.

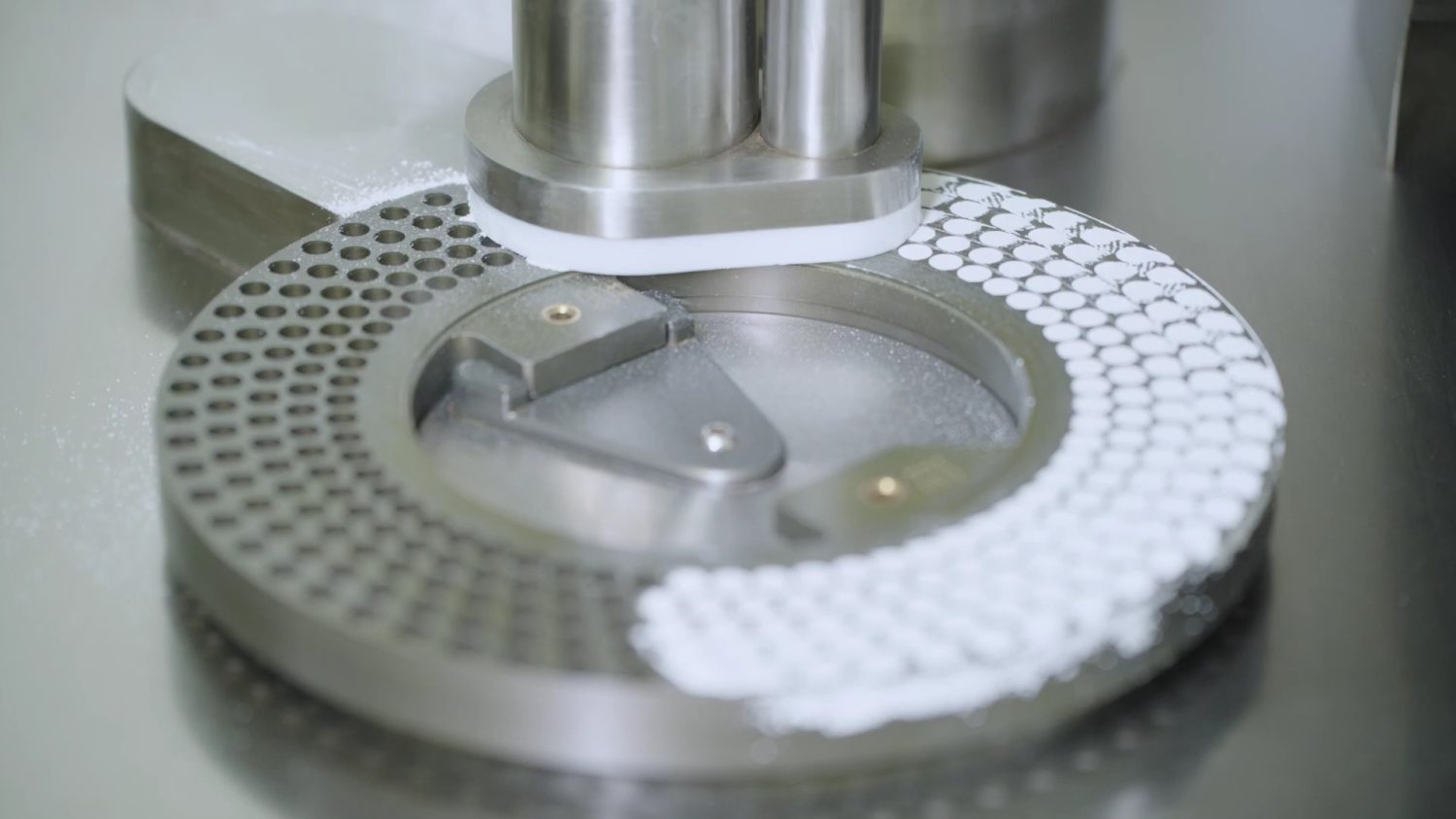

Machine Settings and Performance

The capsule filler plays a big role in achieving consistent fill weight. The Automatic capsule filling machine uses a dosing disc and tamping pins to compact powder into the capsule body. So, the machine must be properly calibrated. Think about it: if the dosing disc thickness or tamping depth is off, you could end up with capsules that are too light or too heavy.

Worn tooling is another issue. It can lead to weight variation across the batch. So, be sure to carry out regular machine maintenance. It’s also a good practice to run periodic weight checks to keep every capsule within spec.

Production Environment

In most cases, capsule filling doesn’t take place in a completely airtight space. That means the production environment should be carefully controlled.

If humidity is too high, powders can clump, and gelatin capsules may soften. If the air is too dry, static will build up, causing powders to stick to the tooling and equipment.

Keeping a stable relative humidity (usually 35–50%) and temperature (20–25°C) helps maintain consistent capsule weight and ensure smooth production.

How to Choose the Right Capsule Size for a Given Weight

We’ve covered a lot about how to achieve the right fill weight. But what if you already know the target weight? How do you figure out which capsule size to use? The answer is to work backward.

1. Calculate the Required Volume

First, find out how much space your formula takes up. Rearrange the earlier formula:

Required Volume (mL) = Fill Weight (g) ÷ Powder Density (g/mL)

👉Example: If your target weight is 500 mg (0.5 g) and your powder density is 0.8 g/mL, the required volume is:

0.5 ÷ 0.8 = 0.625 mL

This tells you the minimum internal volume your capsule needs to have.

2. Match the Volume to a Capsule Size

Once you know the required volume, check the capsule size chart to find the size that can hold at least that much.

For the 0.625 mL example above, the best choice would be a size 0 capsule (0.68 mL capacity), which leaves a little extra room.

3. Round Up if Close to the Limit

If your calculation is very close to or just over the number in the chart, go one size larger. Slight underfilling is fine. Filling right at the limit or even exactly can still lead to overfilling problems.

4. Verify with Test Fills

The capsule size chart and formula only give you an estimate. It’s best to fill a small batch and check the results. This verifies your chosen size works in practice. This step helps avoid material waste and unnecessary production costs.

Practical Tips for Consistent Capsule Filling

📌 Make sure your active ingredients and excipients are evenly mixed. A well-blended formula ensures every capsule delivers the same dose.

📌 Whether using a manual tray or an automatic filler, follow the same steps each time.

📌 If you use a capsule filling machine, check filling components regularly. Clean and replace the worn parts in a timely manner. Proper calibration is also a must.

📌 Weigh a few filled capsules and compare them to your target weight. Adjust the process if you see big differences.

📌 Work in a room with stable conditions to avoid clumping, sticking, or inconsistent filling.

FAQs

Q: How many grams does a capsule hold?

It depends on the capsule size and powder density. For example, a size 00 capsule usually holds over 0.5-1 g of most powders. A size 5 can only accommodate less than 0.15 g.

Q: Why do powders weigh differently in the same capsule?

Because powders have different bulk densities. Fluffy powders take up more space and weigh less. Dense powders pack more weight into the same capsule volume.

Q: How many grams fit in a size 0 capsule?

A size 0 capsule holds about 0.6 g on average. If your powder is very dense, you might fit closer to 0.8 g.

Q: Which capsule size should I use for 1 gram of powder?

You’ll likely need a size 000 capsule. This size can hold 1 gram of most powders. A size 00 might work for very dense powders but will be close to full.

Q: How precise are capsule fill weights?

When your powder is well blended and your machine is properly calibrated, most capsules stay within ±5% of the target weight. Of course, regular weight checks during production are necessary. They help keep batches consistent.