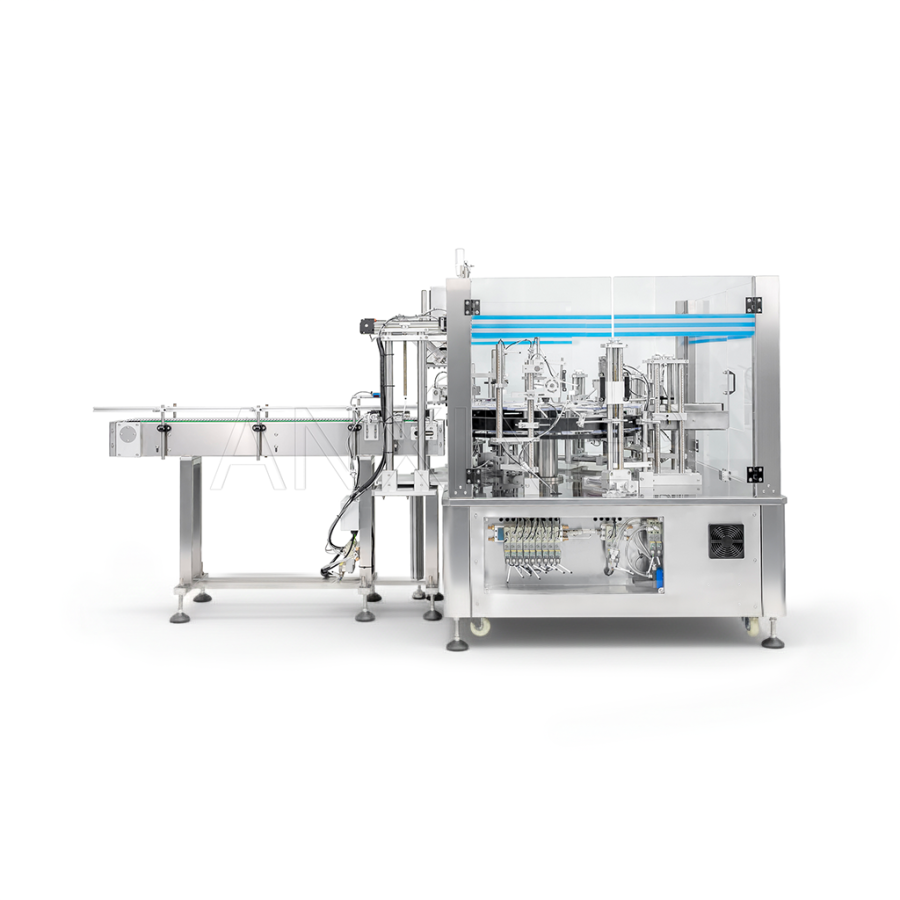

Turntable Cartoning Machine DZH-50S

Vertical Cartoner Machine

Anxine’s vertical cartoning machines are built for precise product handling and exceptional carton presentation, which is vital for the pharmaceutical industry. They erect cartons with precision, then load sensitive items like bottles, vials, blister packs, sachets, and leaflets from the top. Our vertical cartoners meet strict regulatory requirements. They ensure secure sealing, tamper-evident features, and a professional finish. This elevates product protection and market appeal for your products.

Description

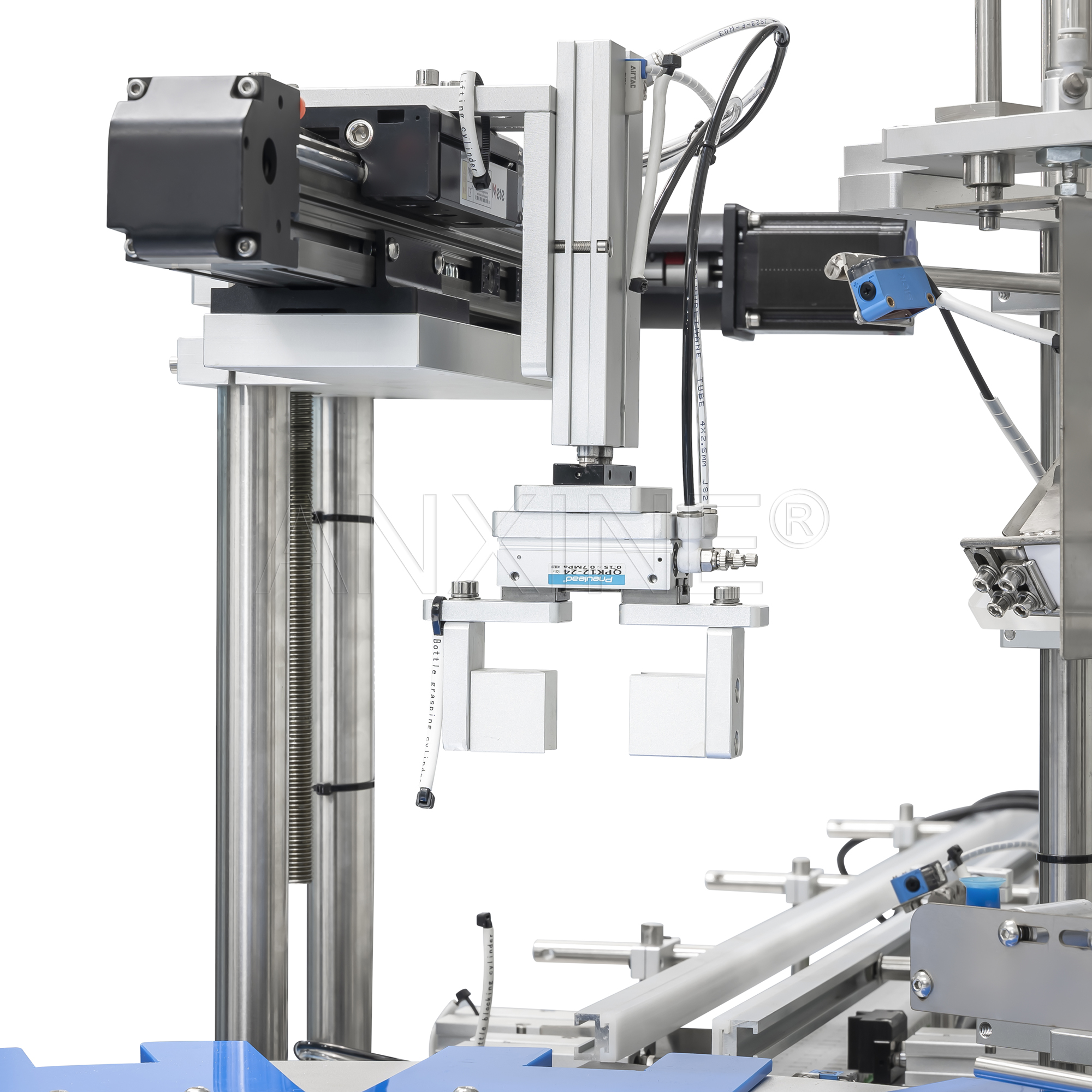

The DZH-50S cartoning machine is an advanced cartoning solution, engineered to streamline packaging processes quickly and precisely. Utilizing vacuum suction cups for carton feeding into its star wheel system, it offers seamless workflow from carton loading through delivery of product.

This machine uses vacuum suction cups to guide cartons into its star wheel. Once inside, this star wheel rotates them towards folding mechanisms for bottom sealing before finally moving them onto top sealing mechanisms for top seal and then out for delivery.

Highlighted Features

- Fully Automated Operation: From collecting cartons to the transportation and placement of finished products, every aspect of this process runs without manual intervention and is entirely autonomous.

- Effective Production Capacity: Production speeds may reach 20-60 cartons/minute, dramatically improving work efficiency.

- Flexible to meet different specifications: supports carton sizes from 60x20x20mm up to 200x80x80mm for product packaging needs of various products.

- Safety Protection Measures: For operator safety, an emergency stop button and protective door have been included to guarantee machine operation safely.

- User-Friendly Touch Screen Interface: Provides an intuitive and straightforward user-interface panel, helping with parameter setup and troubleshooting.

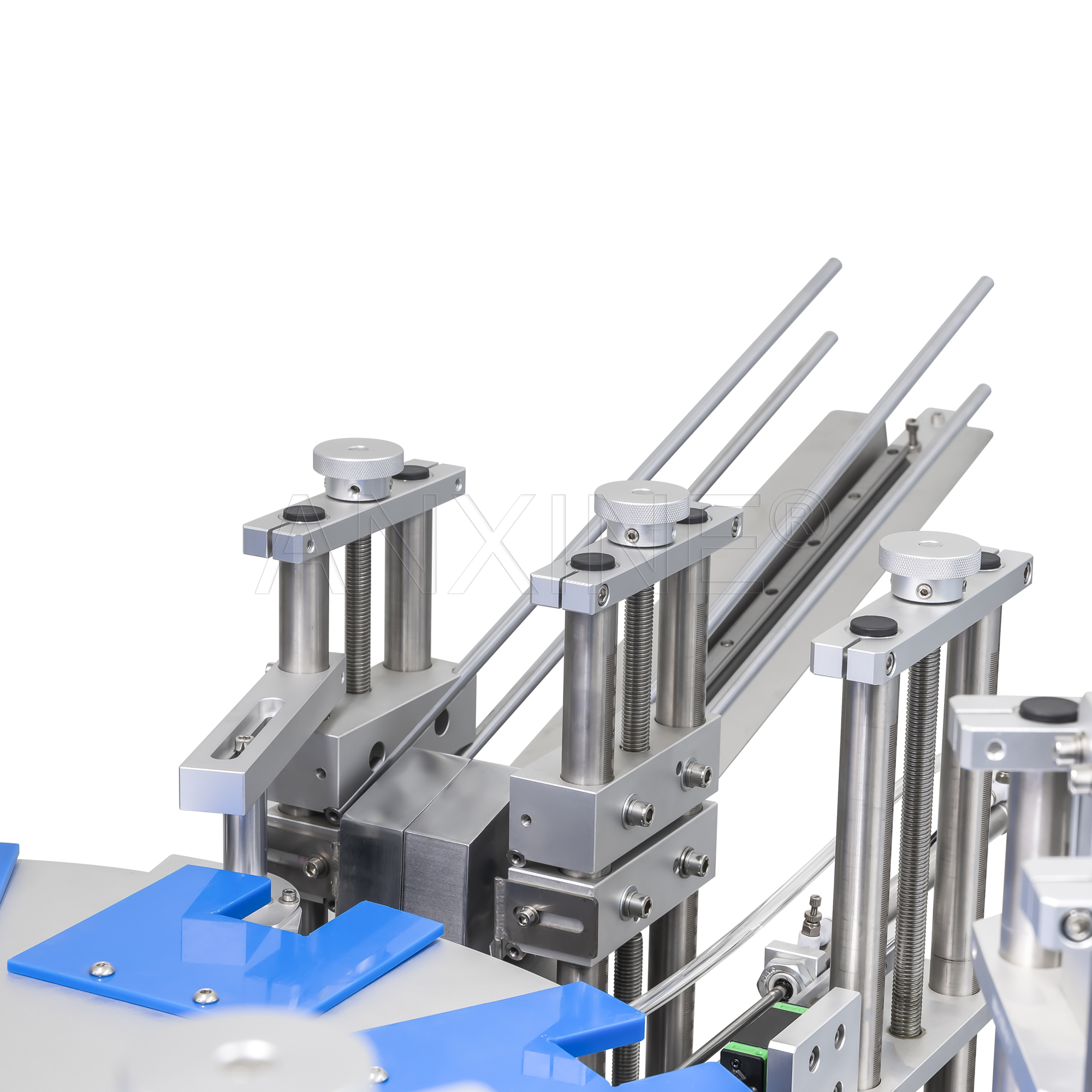

- Fine mechanical adjustment: Each key part such as the carton feeding mechanism or ear folding mechanism can be fine-tuned based on specific circumstances to guarantee optimal working condition.

Specifications

| Model | DZH-50S |

|---|---|

| Carton Dimensions | Minimum: 60x20x20 mm Maximum: 200x80x80 mm |

| Production Speed | 20-60 cartons/min |

| Power Supply | 220V single phase; 50/60Hz |

| Motor Horsepower | 1/4HP 15:1 |

| Air Pressure Consumption | 150L/min |

| Dimensions | 1,750 x 1,200 x 1,500 mm |

| Weight | 950 kg |

Documents

| Name | Size | Download |

|---|---|---|

| Turntable-Cartoning-Machine-DZH-50S.pdf | 408 KB | Download |

Why Choose Anxine

No Anxiety Needed

With Anxine Machinery, rest assured that you are working with a reliable partner committed to meeting all your machinery and production needs efficiently and effectively.

Exceptional Service

Benefit from our exceptional customer service that includes a 1-year warranty and lifetime support, ensuring your equipment remains in optimal condition for years to come.

Quality Assurance

Our products undergo strict quality control measures to ensure reliability and performance. Anxine Machinery is ISO9001 certified and meets GMP and CE standards, reflecting our commitment to excellence.

Innovative R&D

Our research and development team comprises industry experts and technical professionals who continuously drive product innovation and technological advancements, keeping us at the forefront of the pharmaceutical machinery industry.

Global Support

With a robust global network, Anxine Machinery’s products are exported to over 200 countries and regions. We offer 24/7 support to meet client demands and ensure seamless operation worldwide.

Custom Solutions

We understand that every client has unique requirements. Our team excels in providing highly customized solutions tailored to your specific needs, enhancing your production processes.

We Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Supported by expert custom solutions and a robust global service network.

Capsule Filling Machine

Discover capsule filler machines designed for speed, accuracy, and ease of use in capsule production.

Tablet Press Machine

Tablet press machine is a specialized machine for producing tablets and pills.

Softgel Encapsulation Machine

Softgel capsule making machines are suitable for various capsule sizes, leading to smooth and accurate capsule production in the pharma and nutritional industries.

Gummy Making Machine

Good gummy makers improve your supplement or candy line, ideal for making CBD, vitamins, and fruit gummies in the pharma and confectionery industries.

Industrial Powder Blender

Get smooth and consistent mixtures with our industrial powder mixers—great for pharma, chemical, food and cosmetic use.

Pill Counting Machine

Automate your bottling process with our counting machines. Accurate, reliable, and suitable for pills in all sizes.

Blister Packaging Machine

Blister packaging equipment works well with ALU-PVC and ALU-ALU blisters, suitable for packing tablets, capsules, and softgels. It is always applied in pharmaceutical and supplement production.

Cartoning Machine

We offer China cartoning machines for pharmaceuticals, food, and cosmetics. Our carton machines deliver high performance to meet global packaging needs.

Pouch Filling & Sealing Machine

View our selection of pouch filling and sealing machines made for effective packaging. We provide various solutions for food, pharmaceutical, and other industries with our range of automatic and semi-automated pouch filler machines and pouch sealer machines.

Liquid & Cream Filling Machine

They are used to fill various types of liquids, creams, and viscous products into different containers accurately and efficiently.

Empty Capsules

We provide a variety of capsule shells in different sizes and materials for diverse formulations and target groups. They are suitable for the pharmaceutical, nutritional supplement, and functional food industries. We offer immediate-release, enteric-coated, and sustained-release solutions.

TiO₂-Free Capsules

Switch to our TiO₂-free capsules for safer, more reliable protection of your products.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288

Zhejiang, China (GMT+08)