Effervescent tablets are everywhere today. You’ll find them in vitamins, minerals, electrolytes, and even over-the-counter medications. But what does it take to make these tablets? Is their production process the same as regular tablet manufacturing? Are there any tips to produce high-quality fizzy tablets? Keep reading, and you’ll get the answers you’re looking for.

What Makes Effervescent Tablets Different?

Unlike regular tablets, effervescent tabs are designed to dissolve in liquid before consumption. The fizz comes from a controlled reaction between acids and carbonates, typically:

- Citric acid or tartaric acid

- Sodium bicarbonate

When water activates the pair, they release carbon dioxide. This reaction creates the unique bubbling effect. The formula improves taste and mouthfeel, and delivers a faster onset of action for the active ingredients.

Manufacturing of Effervescent Tablets: Two Main Methods

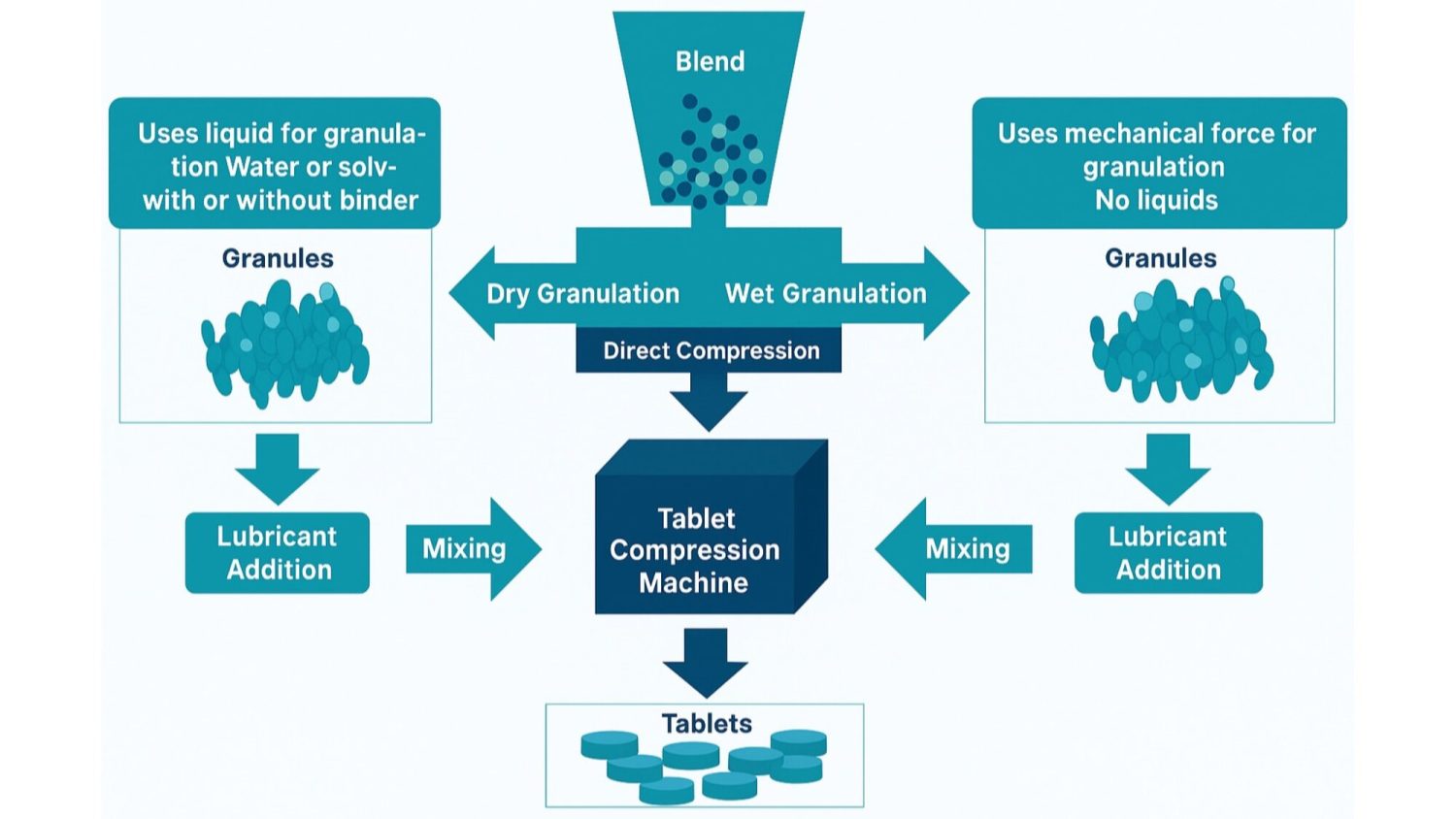

Since they’re a specific type of tablet, the effervescent tablet manufacturing process is similar to that of regular tablets. They usually share common techniques. There are two major methods used to form these fizzy tablets:

1. Granulation Method

If your effervescent powder blend doesn’t flow well or is hard to compact, granulation is the most common and the go-to solution to help. It binds the powder particles together and turns them into more uniform, free-flowing granules. These granules are much easier to compress into high-quality tablets.

This technique can also be divided into two approaches:

a. Wet Granulation

Wet granulation is often the preferred method for effervescent tablet manufacturing. It mixes powders with a binding solution and creates a uniform mix for making tablets with better compressibility and hardness.

You might be confused: Aren’t effervescent tablets sensitive to moisture? Then why is the wet method the most widely used? Of course, the challenge is moisture. Fortunately, modern wet granulation techniques have greatly mitigated this risk.

Acids and carbonates in the effervescent blend can react when exposed to water. To avoid this, these techniques are used:

- Non-aqueous solvents like ethanol or isopropanol

- Minimal liquid binders

- Low-temperature processing

- Fast drying methods like fluid-bed drying

- Humidity-controlled production areas

The wet granulation process can also be carried out in multiple ways:

👉 Two-step method: The acidic and basic ingredients are granulated separately. This is to avoid a premature reaction. They are then dried and mixed before being compressed into tablets.

👉 One-step method: The citric acid and sodium bicarbonate are granulated together using a small amount of liquid, like an organic solvent. This process is often done in a fluid bed spray granulator. The equipment mixes, granulates, and dries the effervescent blend in the same chamber.

👉 Fusion method: This wet granulation method doesn’t need a separate liquid binder, because it can create its own. When the powder blend is heated, the citric acid releases its “water of crystallization.” This component acts as the binder to form granules.

b. Dry Granulation

Dry granulation doesn’t use liquid and a high-heat drying step. So, it’s the alternative when the effervescent formulation is highly sensitive to moisture or heat. This method reduces the risk of premature reaction of acidic and basic ingredients in the effervescent blend. The downside is that it may not always end up with easy-to-compress, free-flowing granules for tabletting.

This method relies on pressure, and there are two ways to prepare granules:

⭕ Slugging: The powder blend is compressed into large, dense tablets called slugs. These slugs are then milled into the desired granule size for final tablet compression.

⭕ Roller compaction: This is a more modern process. The mixed powders are passed between two high-pressure, counter-rotating rollers. When leaving the rollers, the material turns into a compacted sheet called ribbon. This ribbon is then milled into granules.

2. Direct Compression Method

If you’re looking for a simpler and more cost-effective way to make effervescent tablets, direct compression is a solid choice. It bypasses the granulation process entirely. The powders are blended and directly compressed into tablets.

For moisture-sensitive ingredients, like vitamin C and electrolytes, direct compression sometimes does a better job than any form of granulation. Provided that your powder mix already flows well and compacts easily.

How do you successfully get high-quality effervescent products using this method? You only need direct-compressible excipients. For example, maltitol and sorbitol are good fillers because they are water-soluble, low in moisture, and easy to compress.

Here’s why some manufacturers choose direct compression:

- It cuts out the granulation steps, which saves time and cost.

- There’s less risk of exposing the formula to moisture.

- It works well for free-flowing powders and simple formulations.

Granulation vs. Direct Compression

Here’s a quick comparison of the two effervescent tablet manufacturing methods. Take a look to decide which one fits your needs.

| Factor | Granulation | Direct Compression |

| Process | Mix, granulate, dry or mill, then compress | Blend the powders and press them into tablets |

| Production Speed | Slower but more controlled | Faster and fewer steps |

| Equipment | Granulators, mills, and dryers | Just a blender and a tablet press |

| Moisture Risk | Higher risk, especially with wet granulation | Very low as no liquid is added |

| Suitable For | Powders that are dusty, unstable, or hard to compress | Formulas that already flow and compress well |

| Tablet Strength | Usually produces stronger, less brittle tablets | Depends heavily on excipients |

| Flowability | Granules improve flow and reduce dusting | Relies on naturally good flow |

| Cost | More expensive due to extra steps and solvents | More cost-effective to run |

| Typical Use | Pharmaceuticals and large-volume production | Vitamins, electrolytes, simple supplement blends |

Step 1: Prepare ingredients.

Effervescent tablets are used for many supplements and medications. So, the ingredients used in their formulation can vary. But the typical components include:

- Acids: citric acid, malic acid, or tartaric acid

- Carbonates: sodium bicarbonate or potassium bicarbonate

- Active ingredients: vitamins, minerals, or medicines

- Sweeteners and flavors

- Binders and lubricants

Step 2: Weigh and mix all these ingredients.

Depending on the formulas, the proportion of their ingredients may be different. It’s important to ensure how much of a certain ingredient is needed. When everything is decided, use proper equipment to mix them well.

However, if you plan to pick the two-step wet granulation method, the acidic and basic components should be separated to prevent premature reactions.

📍 From here, the manufacturing process can be different.

Step 3A: Apply wet or dry granulation.

Use the appropriate granulation method based on your formulation. You can refer to the earlier section for the differences between the two.

Step 3B: Go straight to compression.

If you’re using the direct compression method, the blend is compacted without any granulation step. Refer back to the previous section for more context.

Step 4: Blend in lubricants.

Once the granules are uniform, add water-soluble lubricants. If you’re not using a granulator machine, add the lubricants to the powders during the mixing step.

Lubricants help the finished tablets to eject smoothly. They ensure the effervescent tablet forms a clear solution when dropped in water.

Step 5: Compress the granules into tablets.

Feed the lubricated granules into a pill tablet press. The machine forms tablets in the desired size and shape. You can also adjust the compression pressure to avoid cracking, sticking, or other defects.

Machines and Equipment Used in Effervescent Tablet Manufacturing

1. Mixers and Blenders

These machines are used to combine acidic and basic components, active ingredients, and excipients to create a uniform blend. High-shear mixers, double cone blenders, or V-blenders are common.

2. Granulation Equipment

The machine choice depends on what granulation method is used. For dry granulation, roller compactors are the most common equipment. And in the wet granulation process, high-shear mixer granulators and fluid bed granulators are widely used. It’s worth mentioning that the fluid bed equipment is so versatile that it performs granulation, drying, and coating in a single unit.

3. Tablet Press Machines

The common types include:

- Single-punch presses

These are easy to use and budget-friendly. Since they only have a single punch-die set, these presses are commonly used for small-scale products.

- Rotary tablet presses

They are more advanced models that run at a high speed. The compression force can be adjusted in these machines. So are a tablet’s thickness and diameter. And many feature a sealed design to prevent moisture exposure.

Key Considerations for Making Effervescent Tablets

1. Moisture Control

Moisture is the biggest threat to effervescent tablets. Even 1-2% water content can lead to a premature reaction between acids and carbonates.

How to do:

- Maintain relative humidity below 20-25% in the manufacturing space

- Keep the room temperature around 18-22 °C

- Use non-aqueous excipients

- Store raw materials in sealed containers

2. Ingredient and Excipient Choice

Each component in effervescent formulas must be dry and stable. Otherwise, they may affect dissolution, taste, hardness, and even the shelf life of the final tablets.

- Citric acid and sodium bicarbonate make up 40-80% of most formulations.

- Moisture content in effervescent granules should stay below 0.5-1%.

- Magnesium stearate is often avoided because it hinders tablet dissolution.

- PEG, PVP, mannitol, and sorbitol are popular binders or fillers.

3. Granulation and Particle Size

Uniform granules are important when making effervescent tablets. They make compression easier and prevent ingredient segregation. For example, the proper granule size should be between 0.2-4.0 mm. The median particle size should be around 400-600 microns. Plus, keeping the dust fines below 10% can improve flow and reduce sticking.

4. Compression Control

Compression force is a key factor in making tablets. Effervescent tablets react as soon as they contact water. So, they need to be hard enough to avoid chipping and soft enough to dissolve quickly. For instance, you usually need to apply 15-150 kN to compress the tablets. The force used to eject the finished tablets is based on their formulation and the equipment.

5. Quality Control Testing

The testing for effervescent tablets is stricter than for regular ones.

- Moisture content should be less than 0.3-1.0%.

- Tablets should fully dissolve within 1-2 minutes.

- Tablets are considered acceptable if their weight loss is below 1%.

- The pH value is between 4.5 and 6.5.

Key Takeaways

- The effervescent tablet manufacturing process needs tighter control than regular tablets.

- Wet granulation is widely used for better flow and compactability.

- Dry granulation and direct compression are used when the formulation is more stable.

- Compression control helps prevent cracking, sticking, and weak tablets.

- Quality fizzy tablets must meet the standards for moisture content, dissolution time, friability, and pH.

- With the growing demand for effervescent tabs, a controlled manufacturing process is the key.