Pneumatic Vacuum Conveyor – ZKS Series

ZKS Series Vacuum Conveyor Systems for Efficient Materials Transfer

The ZKS series is made for manufacturers that need safe, dust-free transfer of bulk solids. In addition to pharmaceutical ingredients and food powders, this vacuum conveyor lineup can even handle fine metal chips.

It’s built with durable stainless steel and uses a dry-running vacuum pump—no oil, no contamination. The setup includes a hopper, filters, and automatic level control. This vacuum conveyor system is quiet, easy to clean, and works well even with tricky materials.

You can choose between intermittent discharge for accurate batch transfer or continuous discharge for long runs and high output. With flexible vacuum conveyor design and reliable components, the ZKS is a solid option for anyone looking for dependable vacuum conveying equipment.

Description

Highlighted Features

- Quick Setup: Easy to assemble and fast to adjust for any setups.

- Sturdy Construction: Built with quality stainless steel for long-lasting use.

- Space-Saving Design: Compact size fits easily into most factory layouts.

- Built-in Filtration: Helps keep materials clean—important for pharma and food use.

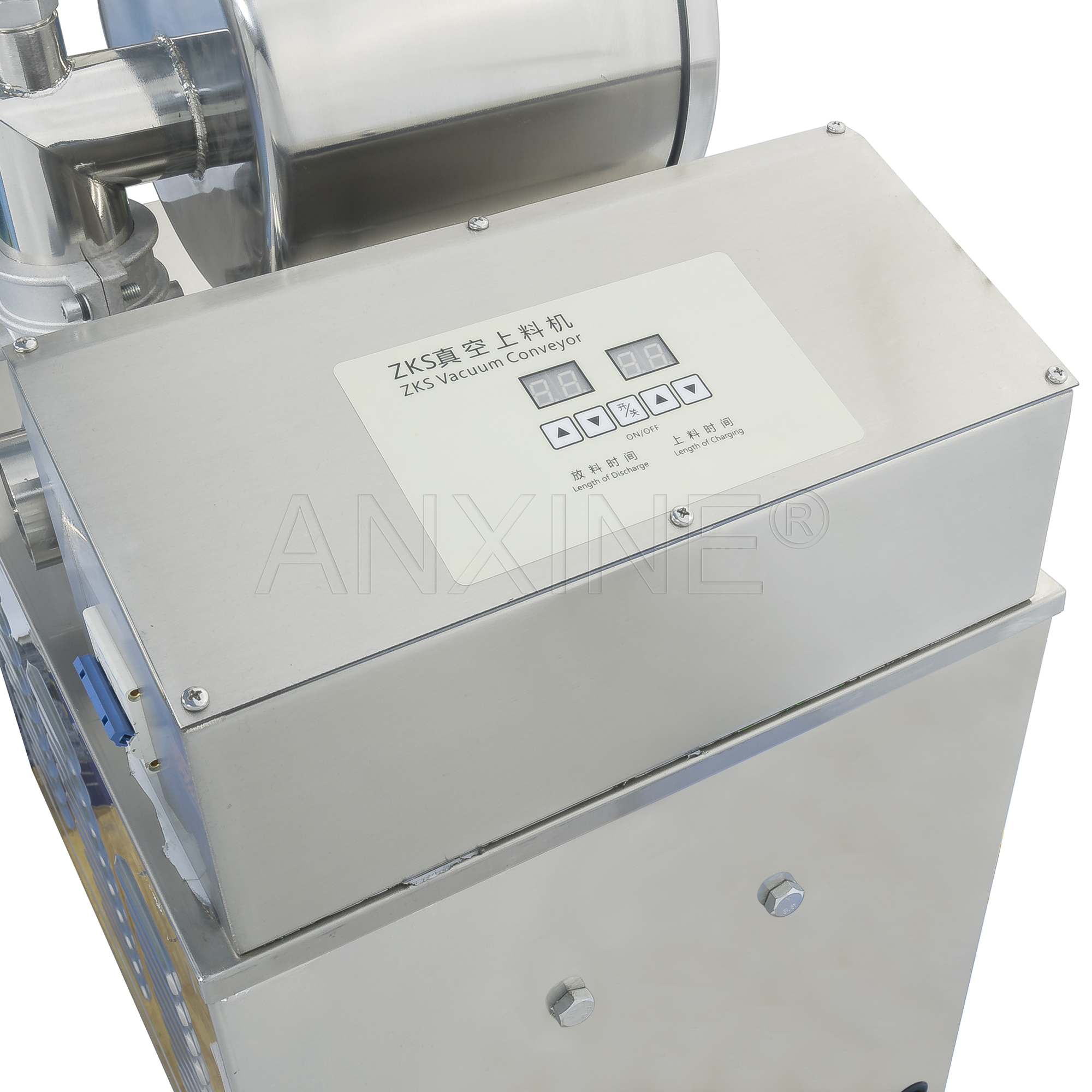

- Simple Controls: Easy to operate with an intuitive control panel.

- Flexible Fit: Works with different materials and setups.

- Safe to Use: Designed to meet industrial safety and hygiene standards.

Specifications

| Model | ZKS-1 | ZKS-2 | ZKS-3 | ZKS-4 | ZKS-5 | ZKS-6 | ZKS-7 | ZKS-10-6 | ZKS-20-5 |

|---|---|---|---|---|---|---|---|---|---|

| Capacity | 400 L/h | 600 L/h | 1200 L/h | 2000 L/h | 3000 L/h | 4000 L/h | 6000 L/h | 6000 L/h | 5000 L/h |

| Power | 1.5 kW | 2.2 kW | 3 kW | 5.5 kW | 4 kW | 5.5 kW | 7.5 kW | 7.5 kW | 11 kW |

| Compressed Air | 8 L/min | 8 L/min | 10 L/min | 12 L/min | 12 L/min | 12 L/min | 17 L/min | 34 L/min | 68 L/min |

| Air Pressure | 0.5-0.6 MPa | 0.5-0.6 MPa | 0.5-0.6 MPa | 0.5-0.6 MPa | 0.5-0.6 MPa | 0.5-0.6 MPa | 0.5-0.6 MPa | 0.5-0.6 MPa | 0.5-0.6 MPa |

| Dimensions | Φ290*802 | Φ290*802 | Φ290*952 | Φ420*1216 | Φ420*1216 | Φ420*1216 | Φ420*1379 | Φ600*1612 | Φ800*2070 |

Documents

| Name | Size | Download |

|---|---|---|

| Pneumatic-Vacuum-Conveyor-–-ZKS-Series.pdf | 459 KB | Download |

Why Choose Anxine

No Anxiety Needed

With Anxine Machinery, rest assured that you are working with a reliable partner committed to meeting all your machinery and production needs efficiently and effectively.

Exceptional Service

Benefit from our exceptional customer service that includes a 1-year warranty and lifetime support, ensuring your equipment remains in optimal condition for years to come.

Quality Assurance

Our products undergo strict quality control measures to ensure reliability and performance. Anxine Machinery is ISO9001 certified and meets GMP and CE standards, reflecting our commitment to excellence.

Innovative R&D

Our research and development team comprises industry experts and technical professionals who continuously drive product innovation and technological advancements, keeping us at the forefront of the pharmaceutical machinery industry.

Global Support

With a robust global network, Anxine Machinery’s products are exported to over 200 countries and regions. We offer 24/7 support to meet client demands and ensure seamless operation worldwide.

Custom Solutions

We understand that every client has unique requirements. Our team excels in providing highly customized solutions tailored to your specific needs, enhancing your production processes.

We Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Supported by expert custom solutions and a robust global service network.

Capsule Filling Machine

Discover capsule filler machines designed for speed, accuracy, and ease of use in capsule production.

Tablet Press Machine

Tablet press machine is a specialized machine for producing tablets and pills.

Softgel Encapsulation Machine

Softgel capsule making machines are suitable for various capsule sizes, leading to smooth and accurate capsule production in the pharma and nutritional industries.

Gummy Making Machine

Good gummy makers improve your supplement or candy line, ideal for making CBD, vitamins, and fruit gummies in the pharma and confectionery industries.

Industrial Powder Blender

Get smooth and consistent mixtures with our industrial powder mixers—great for pharma, chemical, food and cosmetic use.

Pill Counting Machine

Automate your bottling process with our counting machines. Accurate, reliable, and suitable for pills in all sizes.

Blister Packaging Machine

Blister packaging equipment works well with ALU-PVC and ALU-ALU blisters, suitable for packing tablets, capsules, and softgels. It is always applied in pharmaceutical and supplement production.

Cartoning Machine

We offer China cartoning machines for pharmaceuticals, food, and cosmetics. Our carton machines deliver high performance to meet global packaging needs.

Pouch Filling & Sealing Machine

View our selection of pouch filling and sealing machines made for effective packaging. We provide various solutions for food, pharmaceutical, and other industries with our range of automatic and semi-automated pouch filler machines and pouch sealer machines.

Liquid & Cream Filling Machine

They are used to fill various types of liquids, creams, and viscous products into different containers accurately and efficiently.

Empty Capsules

We provide a variety of capsule shells in different sizes and materials for diverse formulations and target groups. They are suitable for the pharmaceutical, nutritional supplement, and functional food industries. We offer immediate-release, enteric-coated, and sustained-release solutions.

TiO₂-Free Capsules

Switch to our TiO₂-free capsules for safer, more reliable protection of your products.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288

Zhejiang, China (GMT+08)