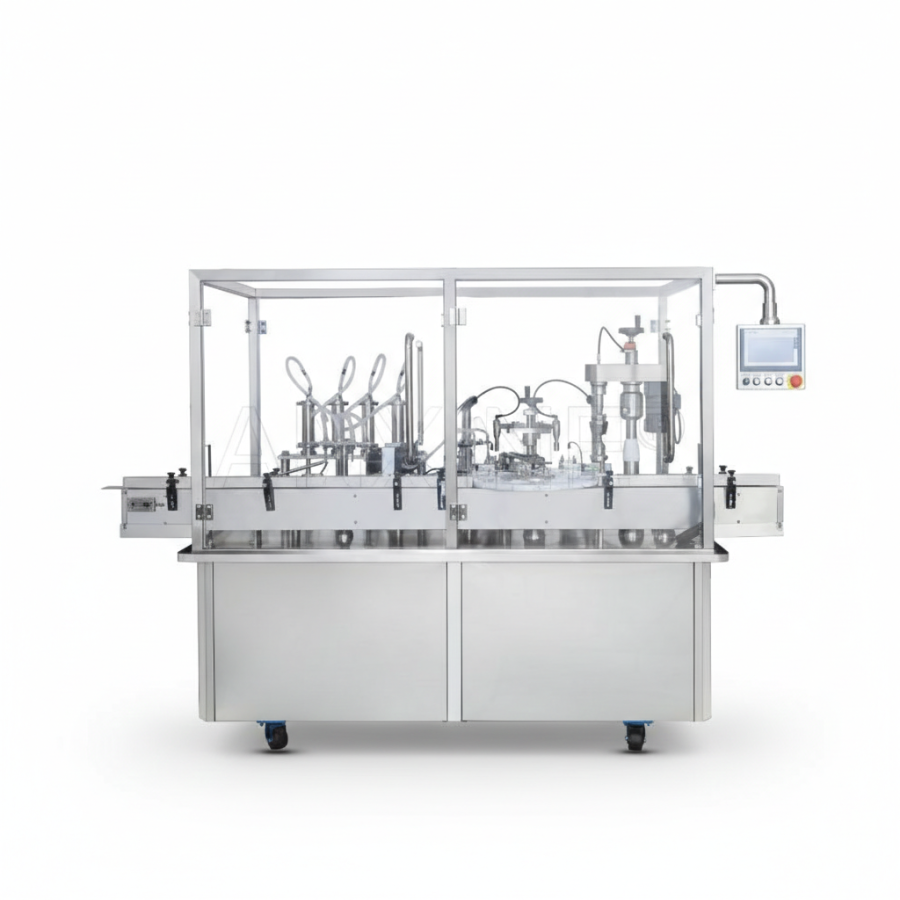

Automatic Dropper Bottle Filling & Cap Screwing Machine C4DY-2

Fully Automatic Filling and Capping Machine for Liquid Bottles

This automatic machine fills and caps small bottles like eye drops, essential oils, and serums. It uses accurate pumps to fill liquids into different bottles, then places and tightens the caps in the right position. The whole process doesn’t need human effort and runs efficiently. The model is often used in food, pharmaceutical, and cosmetic areas. It can handle up to 30 bottles one minute and keeps the filling clean and consistent. With its smart sensors, it can detect the position of bottles. This helps prevent waste and leaking.

The machine uses two types of pumps, piston and peristaltic, to handle different kinds of liquids. The piston pump is good for thicker liquids, while the peristaltic pump works well for thinner ones. All parts that touch the liquid are made from 316L stainless steel, a material that doesn’t rust, and it is safe for medicine. The machine also includes a protective cover to keep the process clean and safe. It fits easily into production lines and works well with other equipment.

Description

The C4DY-2 handles a wide range of materials, including sensitive or viscous materials. It is built to run smoothly, with adjustable parts to fit different bottle sizes.

Highlighted Features

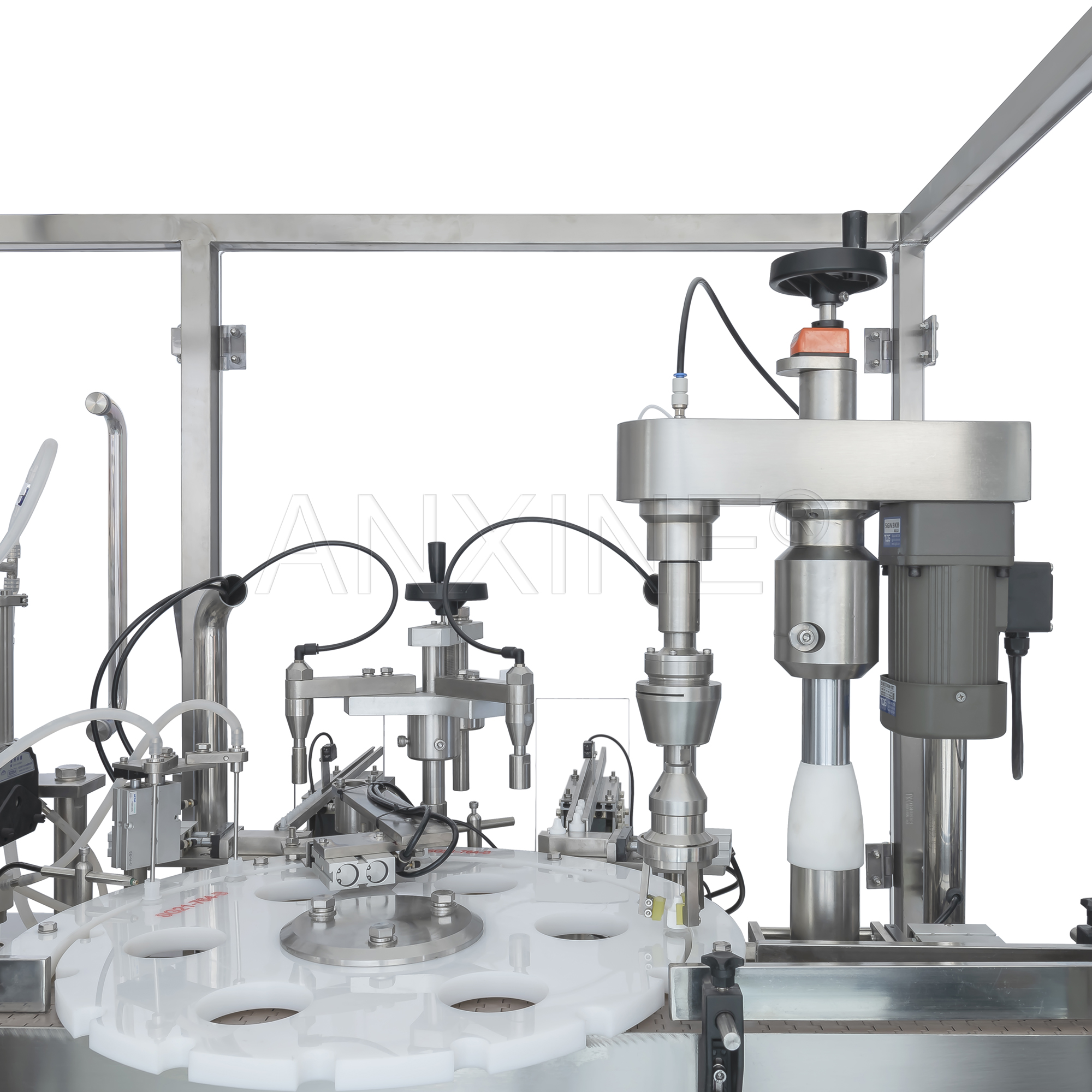

- Two filling systems. It offers piston and peristaltic pumps for different liquid types. Both provide accurate filling with low error.

- Smart Sensors. Sensors detect bottle presence to ensure accurate filling and reduce waste.

- Automatic cap handling. The machine places and tightens caps automatically. It uses a three-claw capping head with adjustable torque.

- Great flexibility. The height and spacing of filling needles and capping heads can be changed to match different bottle sizes.

- Simple Control Panel. Operators can adjust settings easily through the user-friendly screen.

- Stable Operation. It requires a 200–300L air tank to keep air pressure steady and ensure reliable performance.

- Easy maintenance. Parts like the pump and conveyor can be adjusted or cleaned without much trouble, and maintenance steps are simple.

Specifications

| Model | C4DY-2 |

|---|---|

| Production Capacity | 30 bottles/min (four-head filling) |

| Air Pressure | 0.5-0.8 MPa |

| Air Volume | 13-15 m³/h |

| Power Supply | 220V 50Hz |

| Total Power | 3 kW |

| Weight | 950 kg |

| Dimension | 2,400 × 1,650 × 1,700 mm |

Documents

| Name | Size | Download |

|---|---|---|

| Automatic-Dropper-Bottle-Filling-Cap-Screwing-Machine-C4DY-2.pdf | 400 KB | Download |

Why Choose Anxine

No Anxiety Needed

With Anxine Machinery, rest assured that you are working with a reliable partner committed to meeting all your machinery and production needs efficiently and effectively.

Exceptional Service

Benefit from our exceptional customer service that includes a 1-year warranty and lifetime support, ensuring your equipment remains in optimal condition for years to come.

Quality Assurance

Our products undergo strict quality control measures to ensure reliability and performance. Anxine Machinery is ISO9001 certified and meets GMP and CE standards, reflecting our commitment to excellence.

Innovative R&D

Our research and development team comprises industry experts and technical professionals who continuously drive product innovation and technological advancements, keeping us at the forefront of the pharmaceutical machinery industry.

Global Support

With a robust global network, Anxine Machinery’s products are exported to over 200 countries and regions. We offer 24/7 support to meet client demands and ensure seamless operation worldwide.

Custom Solutions

We understand that every client has unique requirements. Our team excels in providing highly customized solutions tailored to your specific needs, enhancing your production processes.

We Offer

Explore cutting-edge pharmaceutical and packaging machinery with Anxine. Supported by expert custom solutions and a robust global service network.

Capsule Filling Machine

Discover capsule filler machines designed for speed, accuracy, and ease of use in capsule production.

Tablet Press Machine

Tablet press machine is a specialized machine for producing tablets and pills.

Softgel Encapsulation Machine

Softgel capsule making machines are suitable for various capsule sizes, leading to smooth and accurate capsule production in the pharma and nutritional industries.

Gummy Making Machine

Good gummy makers improve your supplement or candy line, ideal for making CBD, vitamins, and fruit gummies in the pharma and confectionery industries.

Industrial Powder Blender

Get smooth and consistent mixtures with our industrial powder mixers—great for pharma, chemical, food and cosmetic use.

Pill Counting Machine

Automate your bottling process with our counting machines. Accurate, reliable, and suitable for pills in all sizes.

Blister Packaging Machine

Blister packaging equipment works well with ALU-PVC and ALU-ALU blisters, suitable for packing tablets, capsules, and softgels. It is always applied in pharmaceutical and supplement production.

Cartoning Machine

We offer China cartoning machines for pharmaceuticals, food, and cosmetics. Our carton machines deliver high performance to meet global packaging needs.

Pouch Filling & Sealing Machine

View our selection of pouch filling and sealing machines made for effective packaging. We provide various solutions for food, pharmaceutical, and other industries with our range of automatic and semi-automated pouch filler machines and pouch sealer machines.

Liquid & Cream Filling Machine

They are used to fill various types of liquids, creams, and viscous products into different containers accurately and efficiently.

Empty Capsules

We provide a variety of capsule shells in different sizes and materials for diverse formulations and target groups. They are suitable for the pharmaceutical, nutritional supplement, and functional food industries. We offer immediate-release, enteric-coated, and sustained-release solutions.

TiO₂-Free Capsules

Switch to our TiO₂-free capsules for safer, more reliable protection of your products.

Get in touch with us

Anxine

info@anxine.com

WhatsApp Message

+86-137-5776-3288

Zhejiang, China (GMT+08)