As a common medication type, tablets are widely used in the pharma, supplement and nutritional industries. To make sure effectiveness, tablets are required to conduct quality control. Tablet quality control tests help check if tablets are made correctly. They test many aspects of tablets, like size, weight, strength, etc. Each is used to confirm if the tablet works as it should. That’s why companies must follow strict steps to manufacture tablets. These tests protect both the patient and the company. When doing the test, here are some points you should know.

What is Quality Control for Tablets?

Quality control uses various testing methods to check the tablets during and after production. It makes sure they meet the required standards and confirm that they are safe, effective, and consistent in quality. These tests ensure each tablet has the right amount of medicine and they are not too hard or too soft. Moreover, if tablets are not tested properly, they may not work or harm the person who take them. That’s why every batch of tablets must go through careful testing before it can be sold.

Five Official Tests for Tablets Check

Official tests are also called Pharmacopoeial tests. They are the standard tests required by pharmacopeias like USP, EP, and the Indian Pharmacopoeia. These tests clearly indicate the limits under which tablets could be accepted. They mainly focus on the content of the active ingredient and its in vitro release. All pharmaceutical companies must follow these tests during tablet production. Official quality tests always conclude the following aspects.

Weight Variation

The weight variation test checks if the tablets in a batch have similar weights. Each tablet must have nearly the same amount of drug. If a tablet is too light or too heavy, it may not give the correct dose to the patient. In this test, an analytical balance or digital weighing scale is needed. The tool must be accurate, sensitive, and calibrated. It should measure weight to at least 0.1 mg or 1 mg, depending on tablet size.

During testing, you need to select 20 tablets at random from the batch. Then each tablet is weighed one by one. Next, you should calculate the average weight of the 20 tablets. Then, compare the weight of each tablet to the average weight and check if each tablet’s weight is within the allowed limit.

Please note that the acceptable limits differ in different countries. You should check the pharmacopeia detailedly in your area. Take USP for example. If the average tablet weight is 130 mg or less, each tablet should be within ±10%. If the average tablet weight is 130 mg to 324 mg, each tablet should be within ±7.5%. Here is a chart for your reference.

| Average tablet weight | Difference allowed |

| 130mg or less | ±10% |

| 130–324mg | ±7.5% |

| >324mg | ±5% |

If no more than 2 tablets are outside the allowed range, and none are too far outside the range, the batch passes the test. This testing method is suitable for uncoated or film-coated tablets. For other types of coated tablets, such as sugar-coated or extended-release tablets, content uniformity should be used instead.

Content Uniformity

If the amount of API is less than 25 mg or less than 25% of the total weight, your tablets require a content uniformity test like sugar-coated tablets. It is used when the drug amount is small compared to the whole tablet weight. This checks if each tablet has between 85% and 115% of the labeled amount. This test is key because only the right dose is effective for consumers. A failed result means the drug is not mixed evenly during production.

In this test, the API ingredient should meet the standard of AV according to USP. Inspectors need to test 10 units first. If AV ≤ 15.0%, the batch passes. If AV > 15.0% but the range is within 25%, test 20 more units. In this case, AV must also still be ≤ 15.0%. If they can’t meet the standard, you may need to inspect your manufacturing process in detail at every step. Then, you can find the problem and improve the process, such as adjusting the mixing time. Please note that if yout tablet is a compound formulation with multiple drug ingredients, each ingredient must be tested separately and meet the related requirements.

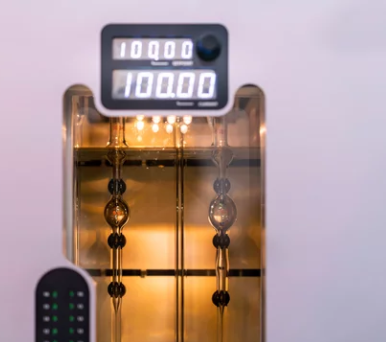

Disintegration Test

The disintegration test checks how fast a tablet breaks down into smaller pieces when placed in a liquid. It is usually water or simulated body fluid, at body temperature (37°C). It checks how fast the tablet falls apart. This test makes sure the proper drug release and absorption.

To conduct this test, you need to use a disintegration tester with 6 or 12 tubes and a moving basket rack. Then, one tablet is put into per tube. Then, you can fill the beaker with the specified liquid. The test should be at 37 ± 2°C, usually for 15–30 minutes. If the test passes, all 6 tablets will fully disintegrate into particles. They will be small enough to pass through the mesh screen at the bottom of the tube. The USP also requires that no hard lumps remain on the screen.

If 1 or 2 tablets fail, you are allowed to repeat the test with 12 more tablets. Now, you have tested a total of 18 tablets. If 16 or more disintegrate, the test passes.

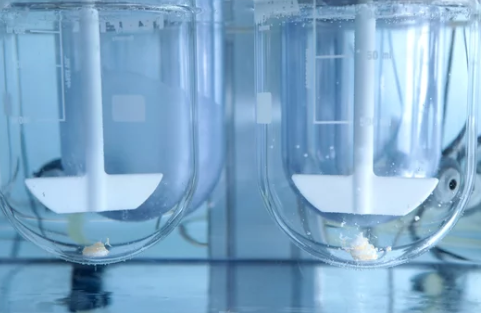

Dissolution Time

The dissolution test checks how fast and how much of the drug in a tablet dissolves in liquid. The dissolving conditions should try to match the human body. This test is used to make sure the tablet releases the drug properly for the body to absorb.

The testing process is similar to the disintegration test. But this testing time is longer, always 30–60 minutes. It requires taking samples of the liquid and measuring how much drug has dissolved. Based on USP, the testing result should not be less than 80% of the labeled amount dissolved in 30 minutes. If you fail the first test, you can conduct it again. Here are the requirements and criteria for your reference. Q means 80%.

| Stage | Number of Tablets | Requirement |

| S1 | 6 tablets | Each tablet ≥ Q + 5% |

| S2 | 6 more tablets | Average of 12 tablets ≥ Q; no tablet < Q – 15% |

| S3 | 12 more tablets | Average of 24 tablets ≥ Q; not more than 2 tablets < Q – 15%, and none < Q – 25% |

If you make sustained-release tablets, controlled-release tablets, or enteric-coated tablets, different testing media and times are needed for quality checks. The compliance standards will also be different.

Friability Check

This test is used to measure the physical strength of uncoated tablets. It checks how easily tablets break, chip, or crumble during handling, such as packaging or transport. It requires calculating the percentage of weight loss and comparing it to the limit. According to USP, the loss should be no more than 1.0%. For example, take 10 tablets for weighing. Each tablet weighs 650 mg.

- Initial weight: 6.500 g

- Final weight after test: 6.435 g

- Weight loss = 6.500 − 6.435 = 0.065 g

- % Friability = (0.065 / 6.500) × 100 = 1.0% → Pass

Note: If friability > 1.0%, the test usually needs to be repeated two more times. Then, the average of the three tests is taken as the final result. It still must meet the requirement of ≤ 1.0%. If the tablets show obvious cracks, splits, or broken pieces, they are considered to have failed the test.

Three Common Unofficial Tests for Tablet Quality

Non-official tablet tests are not mandatory in pharmacopeias, but they are still important. They provide additional insights into the physical and mechanical properties of tablets. These elements are crucial for product development, manufacturing consistency and optimization. Here introduce some common unofficial tablet testing methods.

Tablet Hardness Test

This test checks how much force a tablet can withstand before breaking. This makes sure the tablets are strong enough for handling and packaging but do not affect disintegration or dissolution. Because harder tablets may delay disintegration or dissolution.

You need at least 6 to 10 tablets for the test. During the test, the pressure is gradually applied until the tablet breaks. Then, you should record the breaking force to compare it with the typical hardness range. Different types of tablets have different acceptable ranges. You should find the a suitable one for comparison based on your tablets.

Thickness Test

The purpose is to check if tablets have consistent physical dimensions, especially height. These uniform sizes are helpful for consistent blister packaging and coating application. It also controls tablet weight and drug content indirectly. Since no official standards have been set, the error range is usually determined by tablet manufacturing companies. Most manufacturers set a ±5% to ±7% variation from the average thickness.

Appearance and Odor Check

It is also called organoleptic testing. It uses senses to check the tablets, including appearance, color, smell, taste, etc. High-quality tablets feature a smooth finish. If you find defects like spots, cracks, or damage, these tablets are not qualified for sale. Color helps quickly identify tablets and affects how customers accept the product. Each tablet should have a uniform color. Uneven color, like mottling, means poor quality. When it comes to odor, a strange or bad smell may mean the tablets are breaking down or stored badly. So, odor testing helps confirm the batch is safe and stable.

Sometimes taste should be considered. It is important for chewable tablets or tablets that dissolve in the mouth. This can catch problems early. For example, a fruit-flavored tablet should not smell or taste like mint. Organoleptic testing is usually a preliminary check or a final appearance quality inspection before shipment. It can quickly detect obvious problems.

Tablet quality tests can be done either by the factory itself or by a third-party inspecting company. For official tests, big factories have in-house quality assurance teams to do official tests. Small-scale businesses always choose a third-party lab to do the tests. The testing fee depends on the number and type of tests requested.

How to Do These Tests and How Much Do They Cost?

After the tests, the trusted lab you choose will provide a report or certificate. This report includes sample details, test results, used methods, and a clear conclusion. If the tablets meet the standards, the lab will mark the report as passed. This kind of certificate is often used for product release, audits, or export needs.

For unofficial tests, they are often done by the production or in-process control teams. These tests are not easy to conduct but require carefulness and patience.