As more bottle products are sold in stores and online, the need for fast and accurate labeling keeps growing. Square bottle labeling machines are preferred in many industries, such as supplements, food, cosmetics and cleaning products. They put labels on square bottles correctly and quickly.

Both small and large factories are buying these machines to speed up their work and reduce mistakes. Because of this, square bottle labeling machines are in strong demand and continue to be important in the packaging market. Here are some key points you should know if you want to buy one.

What is a square bottle label applicator?

A square bottle labeling machine is a type of packaging equipment. It is made to stick labels onto square or rectangular bottles. These bottles are often used for products like sauces, shampoos, medicines, and cleaning liquids. These machines can label just one side of the bottle, two sides, or even three sides. Some advanced machines can handle different bottle sizes and shapes by adjusting a few settings.

In addition, they are built to handle flat sides and sharp corners. It helps place labels smoothly and in the correct position, even when the bottle shape makes it more difficult.

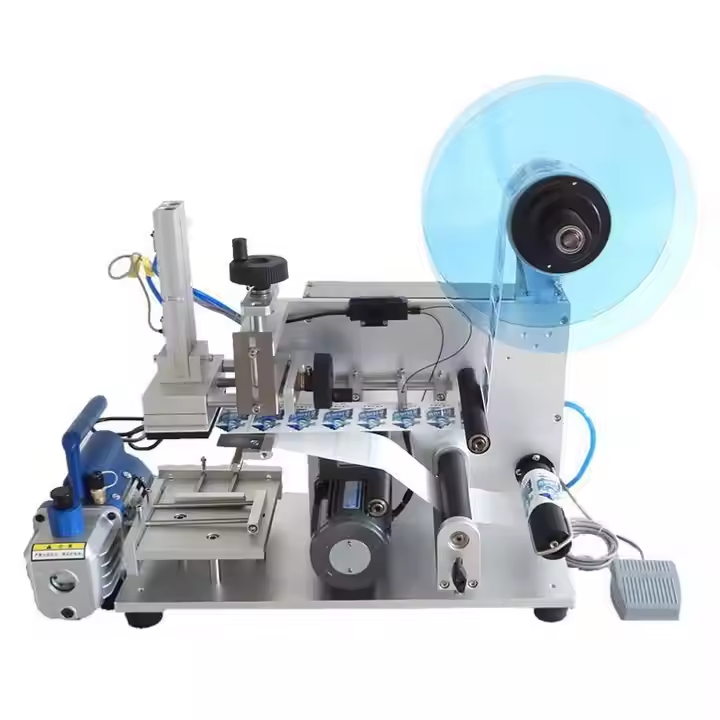

Most square bottle labeling machines come with some common parts. They include a conveyor belt to move the bottles, a label dispenser that feeds the labels, a sensor to check bottle position and a pressing device to stick the label tightly. They work together to stick labels efficiently.

Square bottle vs round bottle labeling equipment

Labeling machines are designed based on the shape of the bottles they handle. The two most common types are machines for square bottles and round bottles. While both serve the same purpose, they work differently due to bottle shapes.

- Bottle shape handling. Square bottle label applicators handle bottles with flat sides and sharp corners, the other is made for smooth and round bottles. It often rotate the bottle as they apply the label.

- Labeling position. Compared to the flexible labeling of square bottle lablers, round bottle ones usually get one full wrap-around label. But some machines can do front-and-back labeling with special sensors.

- Labeling accuracy. Square bottle machines should detect the front edge or corner of the bottle to place the label correctly. Positioning is more complex. For round bottle machines, labeling is often simpler and faster since the bottle turns while the label is applied.

- Speed and cost. Square bottle labeling equipment is usually a bit slower and more expensive. Because it requires more complex handling and sensors. Round bottle labeling machines are often faster and more affordable. Many models are available for small businesses.

Five common types of square bottle labeling equipment

Automatic square bottle labeling machines

This is the most common type used in large factories. This machine works by itself. Workers only need to load the bottles and labels. It uses a conveyor to move the bottles and places the labels with sensors and motors. The machine can label many bottles in a short time, often over 100 bottles per minute. It is controlled by a touch screen, and workers can change the settings easily. This type is good for large factories that need fast and steady production. It also helps reduce mistakes and saves labor costs.

Semi-automatic square bottle labeling equipment

A semi-automatic labeling machine needs more help from workers. The worker puts each bottle into the machine by hand. After that, the machine applies the label correctly. This type is slower than the automatic one, but it is cheaper and smaller. It is a good choice for small businesses, or for companies that only need to label a few bottles each day. It is easy to move, simple to clean, and good for limited space.

Manual square bottle labeling machines

A manual model does not use electricity or motors. It needs a worker to do most of the work by hand. The worker places the bottle in the machine, pulls a handle or presses a lever, and then the label is applied. The label must also be placed or guided by hand. This type of machine is small, light, and easy to move. It is also easy to clean and maintain. This model is the cheapest compared to other types. However, it is slow and not suitable for large production.

Three types mentioned above are classified based on automation levels. Here I introduce you 2 more models based on different functions.

Single-side square bottle labeling machine

This machine is made to label only one side of the square bottle. It is often used when the product only needs a front label, like a logo. The machine uses a sensor to find the front of the bottle and places the label in the correct spot. It works fast and efficiently. It is also a good choice for factories that want to keep labeling simple. Because of the easy setup, many manufacturers like shampoo makers choose this type.

Wrap-around square bottle labeling machines

This type is made to apply one long label that wraps around more than one side of the bottle. It supports to place one label across multiple faces of the bottle, including the front, side, and sometimes even the back. The machine uses rollers or belts to press the label tightly around the corners. Since square bottles have flat sides and sharp edges, the machine needs to be very accurate. It also needs strong pressure to make sure the label sticks well, especially at the corners.

This type of labeling is often used for products that require more information on the label. For example, the front of the label may show the brand, the side may show product details, and the back may include safety or legal text.

How to choose a good square bottle labeler for your business?

A right square bottle labeling machine is important for making your production smooth and efficient. Many machines look similar, but their features can be very different. Below are some key things to think about before making a decision.

Label size and bottle shape compatibility

Not all labeling machines can handle every label size or bottle shape. Some machines are made for small labels, while others can apply large or long wrap-around labels. Also, bottles can vary in height, width, and edge design. Some have straight sides, while others may have curves or taper at the top. So you need to make sure the machine can adjust to your specific bottle shape and label size. A good machine should allow easy changes in settings. Then you can use it for different bottle types if needed in the future.

Production volume

Before buying, you need to know how many bottles you want to label each day or hour. A small manual or semi-automatic machine may be enough for small batches. But for large orders, an automatic machine is better. If you choose a machine that is too slow, it may cause delays. If the labeling equipment is too fast or complex for your needs, you may spend more money than necessary. Thus, it is better to match the machine’s speed with your real production goals.

Space needs

Labeling machines come in different sizes. Some labelers fit on a table, while large ones need a full section on your factory floor. Before buying, check how much space is available in your workshop or production line.

Also, you should consider where workers will stand, where bottles will enter and exit. An open area makes the production more smooth. A compact design is better for small areas, while a bigger system may offer more features but needs more room.

After-sales support

Even the best machines need support after purchase. When contacting suppliers, you’d better check if they offer after-sales service, such as technical help, training, and spare parts. These services help a lot when problems occur during operation. If the machine breaks or parts wear out, a good support system can save a lot of time to fix it quickly.