Dry syrup powders are now everywhere in the food and pharmaceutical world. Why so popular? Because they last longer and stay stable until it’s time to use them. Just add water, shake, and it’s ready. No wonder they’re a go-to choice for many consumers.

But here’s the thing: how to get that powder into bottles or pouches safely and accurately? That’s where the dry syrup powder filler does its magic. This kind of machine helps you fill each package with the exact dose and speeds up production. Want to invest in one in 2025? In this guide, we’ll walk you through everything you need to know before buying a dry syrup powder filling machine. Let’s jump in!

What Is Dry Syrup Powder?

Dry syrup powder is a powdered form of a liquid solution. It’s meant to be mixed with water just before use. Since some ready-made liquids might spoil and lose potency over time, manufacturers offer them in powder form. Just add water, and it turns into syrup ready to use.

While dry syrup is most commonly seen in pharmaceuticals—especially for children’s antibiotics and medicines—it’s also used in other industries:

Nutraceuticals & Supplements: Probiotic powders, vitamin mixes, and herbal extracts often come in dry syrup form for longer shelf life and easier transportation.

Food & Beverage: Instant drink mixes like fruit-flavored syrups, iced teas, or coffee concentrates; powdered sweeteners or flavorings mixed into liquids.

Cosmetics & Personal Care: Some skincare actives (like vitamin C serums) are kept in dry form to stay potent until mixed with a liquid base.

Veterinary & Agriculture: Animal medicines and supplements are also made this way for easier administration.

So, whether it’s a medicine for a child, a DIY skincare solution, or a flavored drink mix, dry syrup powder offers a practical and versatile format.

But why do people choose dry syrup powder over the liquid form? Let’s take a quick look at how it compares to liquid syrup:

| Feature | Dry Syrup Powder | Liquid Syrup |

| Shelf Life | Long (before water is added) | Shorter |

| Storage | Room temperature (before reconstitution) | Often needs refrigeration |

| Shipping | Lighter, no risk of leaks | Heavier, risk of spillage |

| Use | Needs water added before use | Ready to use |

| Stability | More stable without water | Less stable, may need preservatives |

So, dry syrup powders are a smart choice for many medicines. And to package them properly, you’ll need the right dry syrup powder filling machine.

Common Types of Dry Syrup Powder Filling Machines

Choosing the right machine starts with knowing your options. If you’re in the market for a dry syrup powder filling machine, you might’ve come across many different types. Let’s go over each!

Modern dry syrup powder filling machines can be classified by looking at their structural designs, filling mechanisms, and packaging.

Based on structural designs:

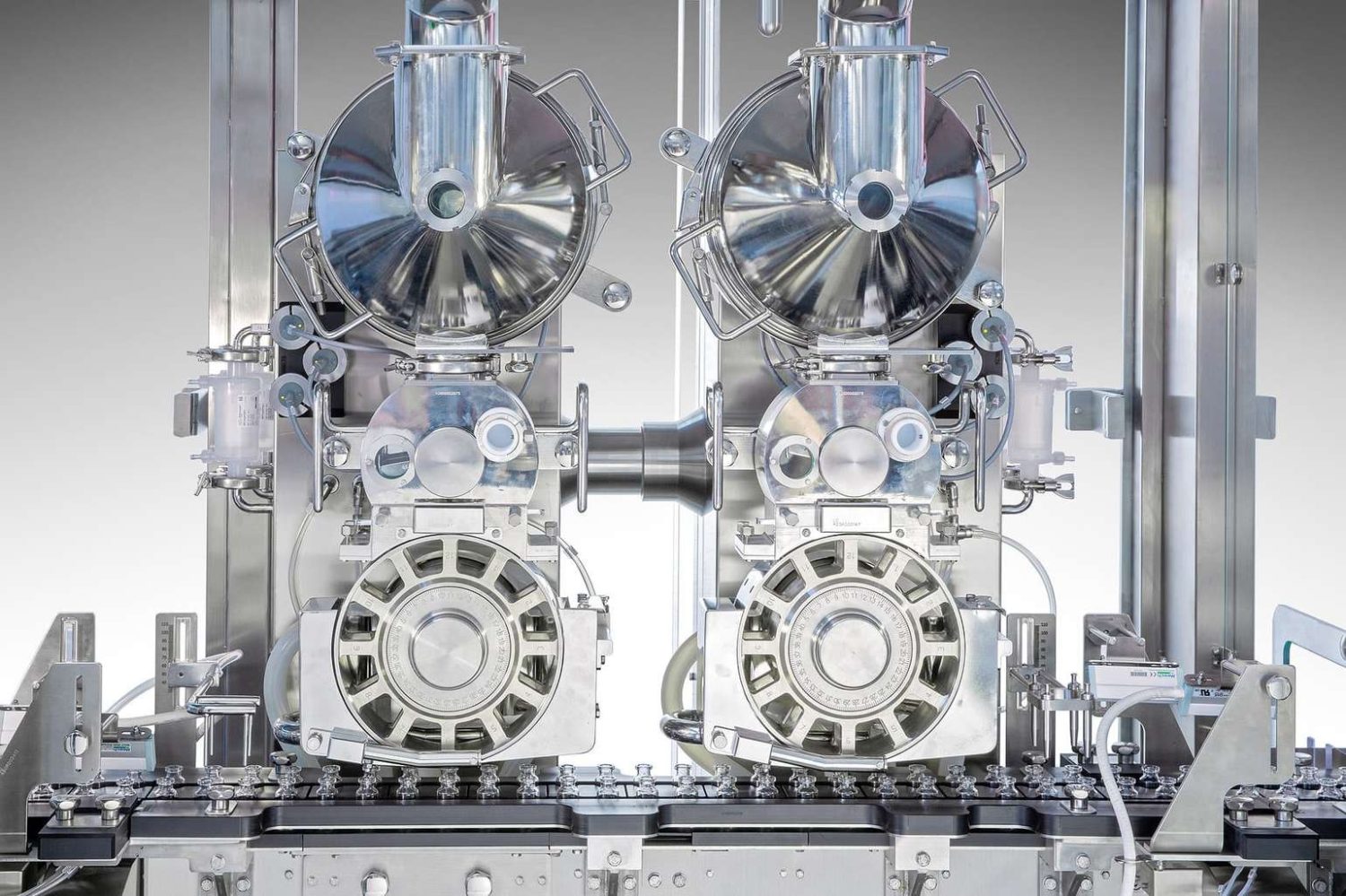

1. Rotary Filling Machines

A rotary dry syrup powder filling machine is a type of high-speed filling equipment. It often uses two round, rotating platforms arranged in parallel. The upper one often has multiple dispensing cones, and the lower one is a starwheel with pockets that align with those cones.

How It Works:

Both platforms do a circular motion. The lower starwheel carries multiple bottles. As they rotate, each cone passes under the filling head and dispenses the exact amount of powder into the bottle below.

Because the machine works continuously without stopping bottles, it delivers a steady and fast output. High-end models can even have 4 filling heads, making them capable of handling hundreds of bottles per minute.

Advantages:

- Very fast and efficient

- Ideal for high-volume production

- Consistent and continuous output

- Great for boosting productivity in large facilities

Limitations:

- Bigger footprint—needs more space

- Mechanically complex

- Higher upfront cost

- Cleaning and maintenance take more effort due to many moving parts

2. Inline (Linear) Filling Machines

An inline dry syrup powder filling machine is engineered to fill bottles in a straight line. You’ll often see a conveyor belt in this type, helping move bottles through. It’s a popular pick for smaller or mid-range production runs.

How It Works:

Bottles are carried in a single line down the conveyor belt. They stop briefly one by one under the filling head. Most inline machines have fewer heads (usually 1 to 4), so they fill bottles one batch at a time. That means they’re slower than rotary machines, but still reliable for many operations.

Advantages:

- Compact design—takes up less space

- Lower cost compared to rotary systems

- Easier to clean, maintain, and operate

- Great flexibility for different bottle sizes or powders

- Scalable—you can add more filling heads as your needs grow

Limitations:

- Slower filling speed

- Lower output compared to rotary machines

- Small pauses during filling reduce throughput

Based on filling mechanisms:

1. Auger Filling Machines

An auger filler is one of the most common tools used to fill dry syrup powder. It’s known for being reliable, accurate, and flexible. You’ll find it in many pharmaceutical and food powder packaging lines.

How It Works:

The system uses a rotating auger screw inside a hopper. As the screw turns, it pushes a set amount of powder into each bottle. The rotation is usually controlled by a servo motor or a set number of turns.

To keep powder flowing smoothly, the hopper often has agitator blades that stir the product. This helps prevent clumping and ensures consistent dosing—even with fine, dusty powders.

Advantages:

- Very accurate—dosing errors can be less than 1%

- Works for both free-flowing and sticky powders

- Easy to clean and switch between different product sizes

- Can be used in both inline and rotary filling machines

- Minimal dust when enclosed properly

Limitations:

- Accuracy depends on consistent powder density

- Very light or sticky powders may need special auger designs

- Some powders might be better handled with vacuum systems

2. Vacuum Filling Machines

A vacuum dry syrup filling machine fills bottles by sucking the powder in with a vacuum. It’s a great option for handling fine, light, or clumpy powders that are hard to manage with other filling methods.

How It Works:

The machine creates a vacuum to pull powder into a dosing wheel. Once the right amount is collected, the vacuum releases the powder into the bottle. This process is gentle and helps keep the powder flow consistent, even for powders that don’t move well on their own.

Advantages:

- Works well with fine, dusty, or non-free-flowing powders

- Reduces airborne dust and contamination

- Can be designed as a closed system for better hygiene

- Often matches auger fillers in accuracy

- Helps reduce air pockets in filled bottles

Limitations:

- Not as fast as auger fillers when filling the same volume

- Pricier due to the built-in vacuum features

- Maintenance is key—filters, seals, and pumps need regular checks

- Not ideal for every powder or production speed requirement

Dry syrup powder filling machines also come in different types, depending on the packaging style: bottles and pouches.

For bottles, the most common options are auger fillers and vacuum fillers. Each has its own way of measuring and dosing powder, depending on the powder type and required accuracy.

For pouches, machines like a vertical form-fill-seal machine and a pre-made pouch filler are used. These systems usually work with small doses and are great for sachets or stick packs. Whether you’re filling bottles or pouches, there’s a machine designed to match your production needs and powder type.

Key Features to Look for in a Dry Syrup Powder Filling Machine

| Feature | What to Look For | Why It Matters |

| Filling Accuracy | Servo-driven auger fillers for precise controlIntegrated checkweighers for real-time feedback±1% or better fill toleranceDual-speed filling (fast fill + slow top-up) | Ensures each bottle receives the correct amount of powderCritical for patient safety in pharma productsHelps meet regulatory requirements |

| Speed and Throughput | Throughput in bottles per minute (BPM)Rotary machines: 100–200 BPM for high-volume needsInline machines: 20–60 BPMOption to add more filling heads later | Prevents slowdowns in your production lineLets you match output to your demandFuture-proofing if you plan to scale operations |

| Hygiene and Cleanability | Stainless steel 304/316L contact partsSmooth, crevice-free surfacesTool-less disassembly of hopper/augerCIP (Clean-in-Place) capabilityDust collection or enclosed filling zones | Keeps the machine clean and sanitaryPrevents cross-contamination between batchesReduces cleaning time and supports GMP compliance |

| Automation and Controls | PLC-based system with touchscreen HMISave and recall recipes for different products”No bottle, no fill” sensorsBottle reject mechanisms (under/overfill)Integration with cappers, labelers, conveyorsOptional Industry 4.0 features (remote monitoring, batch data logging) | Simplifies daily operation and changeoversCuts down on operator errors and product wasteBoosts consistency and traceability across batches |

| Flexibility & Compatibility | Handles different bottle sizes and fill weightsQuick-change parts for fast format shiftsAdjustable fill speeds and nozzlesVibrators for powder settlingWorks with various powder types (free-flowing to clumpy) | Lets one machine handle multiple product typesSaves space and investment costIdeal for R&D labs, contract manufacturers, or growing brands |

| Regulatory Compliance | CE marking for safety standardsGMP-compliant design (easy to clean, non-toxic materials)ISO-certified build qualitySupport for FDA validation documents (IQ/OQ)Electrical certifications (UL, CSA) | Ensures compliance with international standardsSpeeds up audit and approval processesIncreases buyer and regulator confidence in your facility |

Dry Syrup Powder Filling Machine Price Ranges (2025)

One question that comes up a lot from buyers is: “How much does a dry syrup powder filling machine actually cost?” We’ve done a bit of digging to find out the price range of the different types of dry syrup powder fillers available, and here’s what we discovered:

- Manual/Small-Scale: <$1,000 up to $2,000 (basic units; low throughput).

- Semi-Automatic: $3,000 – $10,000 (single to dual head auger fillers; moderate throughput).

- Fully Auto Inline: $10,000 – $50,000 (multi-head inline systems; medium-high throughput).

- Rotary High-Speed: $50,000 – $150,000+ (large multi-head rotary lines; high throughput; price varies widely by customization).

FAQs About Dry Syrup Powder Filling Machines

Q1: What’s the ideal filling machine for a startup or small production?

A semi-automatic dry syrup powder filling machine is a good choice. It’s budget-friendly, simple to operate, and fits easily in smaller spaces. You’ll still get accurate fills without spending too much. If you’re just starting out, a single-head auger filler is often the go-to option. It can fill a few hundred bottles per hour—great for low to mid-size batches.

Q2: How do I clean and maintain a dry syrup powder filling machine?

Clean all product-contact parts after each use. That includes the hopper, auger, and nozzles. Use a soft brush, cloth, vacuum, or mild cleaner. Wipe down outside surfaces too. Lubricate moving parts regularly. Follow the maintenance schedule from the supplier.

Q3: Can I fill different types of powder with the same machine?

Yes, many machines can handle different powders. For example, an auger filler can work with both fine antibiotic powder and coarser supplements. You may need to adjust settings or switch parts like the auger screw or funnel. Just make sure to clean the machine well between products to avoid mix-ups.

Q4: How long do these machines usually last?

A good filling machine can easily run for 10 years or longer. Some last even 15–20 years with proper care. Clean it regularly, replace worn parts, and don’t overload it. Machines from reliable brands often come with strong support and spare parts, which makes a big difference in the long run.