These days, many medicines and supplements shine like candy. That’s thanks to their outer layer, known as the coating. But that coating does far more than make these pills look pretty. It improves taste, protects actives, and manages how the medicine is released. No wonder there are so many types of coatings out there.

Sugar coating, film coating, and enteric coating are the three most common types. So, what makes each coating different, and which option fits your formula best? Let’s find out together.

What Is Sugar Coating?

Sugar coating is the oldest tablet coating approach. It’s still used today for specific pharma products. Unlike other coating types, it’s only for tablets. This method coats tablets with several layers of sugar syrup to form a smooth, thick shell. The shell tastes sweet and hides odors. On top of that, it adds a protective barrier for the active drug.

As mentioned earlier, sugar coating requires many syrup layers. This makes the process labor-intensive and time-consuming. It can double the size and weight of the tablet. People might find it uncomfortable to ingest.

How Do You Sugar Coat Tablets?

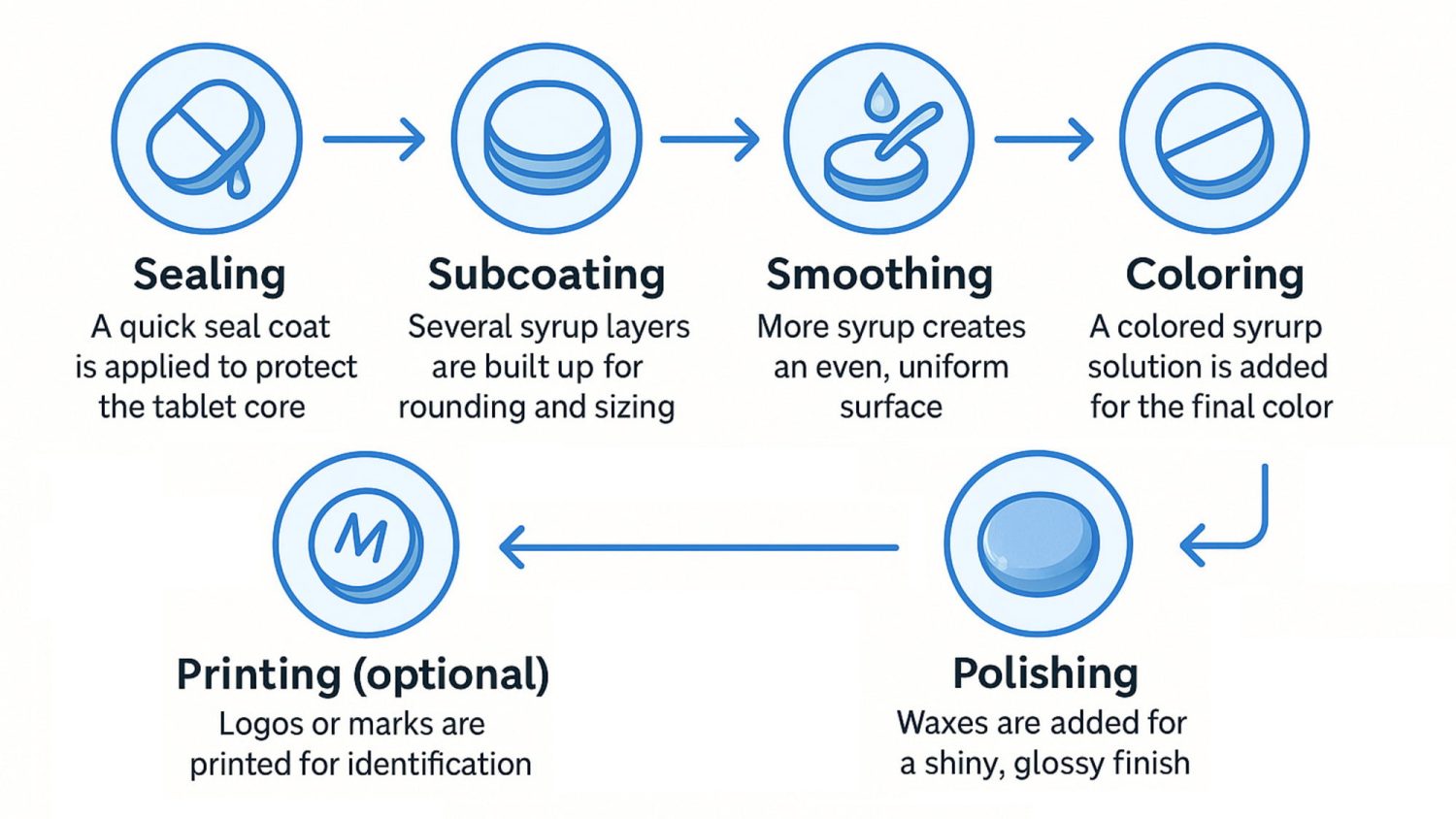

The process usually happens in six main stages:

- Sealing: A seal coat is applied to the tablet core to shield it from moisture.

- Subcoating: The tablet is covered with several layers of syrup to get rounded edges and the desired size.

- Smoothing: More syrup is applied to create an even surface.

- Coloring: A colored sugar solution is used to dye the tablets.

- Polishing: Waxes like beeswax or carnauba are used for that glossy shine.

- Printing (optional): Logos or dosage marks are added for branding.

Advantages and Disadvantages of Sugar Coating Tablets

Advantages:

- The thick sugary coating completely hides the bitter taste of the medicine. You’ll mostly taste sweetness when the tablet touches your tongue. This is great for children and anyone sensitive to unpleasant tastes or smells.

- The coating goes through multiple stages to form that smooth, shiny finish. The shell can be tinted, too. So, you’ll get tablets with a colorful, recognizable look.

- The finished coating also acts as a physical barrier. If you’re handling sensitive ingredients, it protects them from moisture or light to some extent.

Disadvantages:

- Layers of sugar syrup make the coating very bulky. In some cases, the tablet can be 2-3 times bigger or heavier than the core.

- Sugar dissolves quickly in water. That’s a problem if you want to produce controlled-release drugs.

- Each layer of sugar must be dried before the next one is applied. So, it takes many hours or even days to complete the process.

- Because it’s time-consuming, sugar coating tablets is not suitable for mass or high-speed production.

Examples of Sugar-Coated Tablets

Some classic examples include older formulations of painkillers and supplements. For instance, Accord 200 mg ferrous sulfate tablets and Advil 200 mg ibuprofen tablets were traditionally sugar-coated. Poten-Cee Ascorbic Acid is a famous vitamin C supplement known for its sugar-coated form.

What Is Film Coating?

Film coating is the most common modern coating method. It’s an upgrade of sugar coating, which means it forms a thin polymer-based layer instead of a thick sugar shell. The film can be as thin as a human hair strand, less than 100 microns. Even though the coating is thin, it’s very flexible. And just like sugar coating, it can also be colored.

Film-coated pills are slick, glossy, and tasteless. The coating there is to protect the drug and control its release. You can adjust the film coat’s formula to make the tablet or capsule dissolve more slowly or in a targeted spot. That’s how we get extended-release, delayed-release, and enteric-release products.

Film coating is much faster than sugar coating. It’s done in a single step, and drying happens continuously. For these reasons, film coating has largely replaced sugar coating in modern pharma. Nearly all prescription and OTC pills today are film-coated.

What Is the Process of Film Coating?

As touched on earlier, film coating is completed in a single step. In practice, that means several key actions happen at once. Here’s a closer look:

- Preparing: Blend the polymer, plasticizer, colorant, and solvent to form the coating liquid.

- Loading: Tablets are placed in a coating pan or perforated drum.

- Tumbling: The coating pan or perforated drum rotates to tumble the tablets.

- Spraying: The tablet coating machine sprays the coating liquid onto the tablets.

- Drying: Warm air is directed into the pan to dry the solution on each tablet surface until a thin film forms.

Advantages and Disadvantages of Film Coating

Advantages:

- A film coating is very thin, so it won’t make the pill bigger or heavier.

- Film-coated tablets are easier to swallow because of their slick surface. You usually need less water than swallowing an uncoated pill.

- The coating masks bitter taste or smell and protects sensitive APIs from the environment.

- You can use specific polymers to create different functional coatings.

- Film coating is fast and simple, ideal for high-speed lines.

Disadvantages:

- The final finish may not be as glossy as sugar-coated tablets.

- You need premium polymers and, in some cases, special solvents, too. This can add cost.

- Tight process control is needed at every stage, from the formulation to the equipment settings.

Examples of Film-Coated Drugs

Almost every modern tablet you buy at the pharmacy is film-coated. For instance, Tylenol Extra Strength Acetaminophen comes as white film-coated tablets. The label even explicitly calls it “COATED”. If you look up the official FDA label for many OTCs on DailyMed, you’ll see “film coated” mentioned right in the name or description.

What Is Enteric Coating?

Enteric coating is a special kind of film coating. It’s designed to resist acid and dissolve only in a higher pH environment. This means an enteric-coated tablet or capsule won’t break down in your stomach. It stays whole as it travels through the stomach. Its active ingredient will be released and absorbed only in the small intestine. We can say that enteric coatings protect the drug.

Medicines like aspirin can upset your stomach or cause nausea if they dissolve too early. Enteric coatings stop the drug from breaking down in the stomach. In this way, the stomach lining can be protected.

Enteric coating is also a form of delayed-release technology. Depending on when and what you eat, the coated drug may take 2 to 7 hours to dissolve and release.

How the Enteric Coating Process Works

Enteric coating follows a process similar to film coating. The big difference is that it uses acid-resistant polymers like CAP or PVAP. Let’s see how it coats: you prepare an enteric polymer solution; load tablets into the coating machine; tumble the tablets and spray the solution onto them; and use heated air to dry and cure the film.

In practice, you don’t need special equipment for enteric coating. The same film-coating machine can do the job. The only change is the coating formula. With the right recipe, the machine can produce enteric-coated tablets just as efficiently as a normal film-coated one.

Advantages and Disadvantages of Enteric Coating

Advantages:

- The main advantage is the acid barrier. It lets sensitive drugs survive in the stomach acid and be released right in the intestine.

- The coating greatly reduces gastric side effects. It protects the stomach lining from being irritated.

- It’s tailor-made for medications that must act in the gut rather than the stomach.

Disadvantages:

- Enteric-coated drugs don’t act right away, so they’re not the best choice for fast pain relief.

- Even though some film-coated tablets can be split as advised, the enteric ones should never be crushed or cut. Doing so destroys their acid-protective barrier.

- Enteric polymers are more expensive than normal film polymers. This makes enteric tablets more costly to produce.

Examples of Enteric-Coated Medications

Many low-dose aspirin tablets are enteric-coated to protect the stomach. If you look closely, labels will say “Enteric Coated” or “Gastro-Resistant.”

Another example is fish oil capsules. Some brands offer enteric-coated products to avoid fishy burps. And many probiotic supplements use an enteric coat too. It ensures the live bacteria survive stomach acid.

If a product advertises “EC” or says “DO NOT CRUSH,” it likely has an enteric layer.

Sugar Coating vs Film Coating vs Enteric Coating: Side-by-Side Comparison

Now that we’ve covered the basics, you might be wondering how these coating types truly differ. Let’s put them next to each other and compare:

| Feature | Sugar Coating | Film Coating | Enteric Coating |

| What It Is | Thick, candy-like sugar shell applied in many layers | Thin, flexible polymer film | A special type of film coating that resists stomach acid |

| Main Purpose | Improve taste and appearance; mask odor | Protect drug, improve swallowability, and adjust release | Protect drug from stomach acid and avoid gastric irritation |

| Where It Dissolves | Breaks down quickly in the stomach | Usually dissolves in the stomach (unless modified-release) | Only dissolves in higher-pH environment (small intestine) |

| Impact on Size | Can make tablet 2-3× larger and heavier | Minimal size increase; barely noticeable | Slightly thicker than standard film coat, still thin |

| Production Speed | Slow; many steps and long drying time | Fast, continuous process | Similar to film coating schedule; formula change only |

| Taste & Odor Masking | Excellent, sweet flavor and complete taste cover | Good, smooth, tasteless surface | Good, but main function is protection, not taste masking |

| Release Control Options | Not suitable for controlled release | Can be tailored for immediate-, delayed-, or extended-release | Specifically designed for delayed, gut-targeted release |

| Best For | Chewables, pediatric meds, supplements, products focused on taste & appearance | Modern tablets and capsules, high-volume production, flexible release profiles | Acid-sensitive drugs, stomach-irritating drugs, probiotics, fish oil, low-dose aspirin |

| Drawbacks | Bulky tablets, long process, not fit for high-speed lines | Needs good process control; costlier polymers than sugar | Higher material cost; slower onset; cannot be crushed/split |

FAQs

Q: How can I tell if a pill is sugar-coated, film-coated, or enteric-coated?

A: Look at the surface. A sugar-coated tablet will look glossy and often thick, like a candy. A film-coated tablet will have a smooth but less shiny surface. An enteric-coated tablet might look like a film-coated one, but sometimes has a subtle imprint like “EC”. The package may also say “Enteric Coated” or “Gastro-Resistant.”

Q: Is film coating the same as enteric coating?

A: No. Film coating generally dissolves in stomach acid soon after swallowing. Enteric coating is a special film coat that resists stomach acid and only dissolves in the intestines. In other words, all enteric coatings are film polymers, but not all film coatings are enteric.

Q: Can I chew or crush a coated tablet?

A: You shouldn’t. If you chew a sugar-coated tablet, you’ll lose the sweet layer and get a mouthful of bitterness. Some film-coated tablets can be split if they have a score line, but they’re still not meant for chewing. And for enteric-coated pills, never crush them. It destroys the acid-resistant coat.