Tablet counting equipment is widely used in the pharmaceutical and supplement industries. They fill a set number of tablets into bottles accurately. If you want to buy a good tablet counter, it is important to know how they work. This article helps you have a thorough understanding about this.

- Meaning of tablet counting machines

- Six main parts of a tablet counter

- The working principle of this equipment

- Three tips to choose a suitable one

What is a tablet counting and filling equipment?

This machine counts tablets and fill the accutrate number of them into bottles or other containers. Most machines have sensitive sensors. They detect each tablet as it passes through the counting area. The machine then automatically stops filling once the correct number is filled. Many models suit different sizes and shapes of tablets for a wide application. These machines are available in semi-automatic and fully automatic versions.

Tablet counting and filling machines are always used in pharmaceutical area. They pack tablets, capsules, and softgels into bottles. Each bottle contains the exact and same number of doses required, whether for prescription or over-the-counter drugs. In the nutraceutical industry, these machines pack vitamins, dietary supplements, and herbal tablets.

Importance of precise counting

Accurate counting is key in both pharmaceutical and supplement production. If a bottle contains tablets incorrectly, it may cause regulatory and healthy problems. Clean filling is also important. Because dust or broken tablets would influence the quality and cause contamination.

Six main parts of tablet filling machines

A pill counting machine has many parts you should know for better operation.

Hopper

The hopper is always on the top of the machine. It is a large container that holds the bulk tablets before operation. The hopper has a smooth surface to reduce dust buildup. When tablets are poured into the hopper, they are stored there until the next step begins.

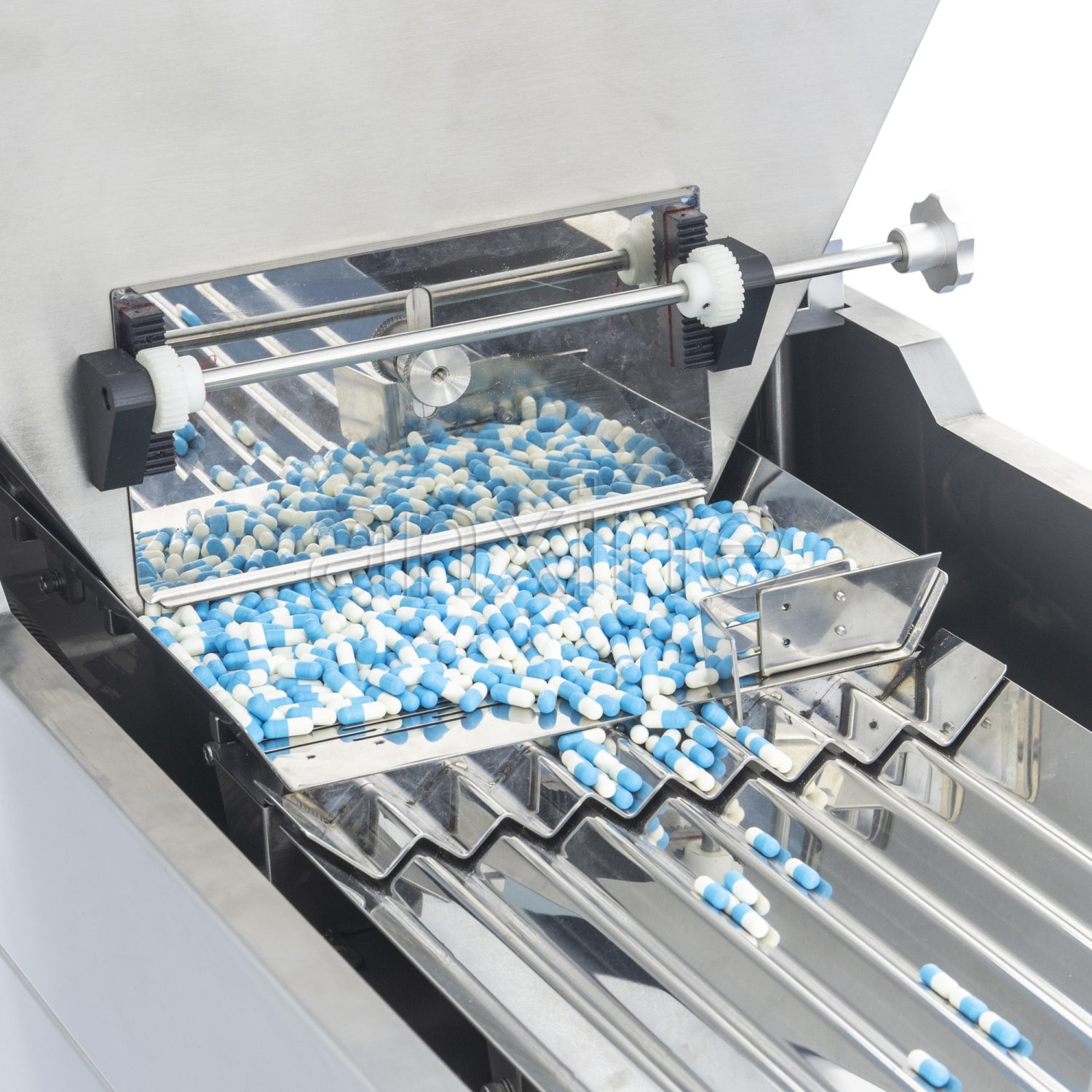

Feeding Part

The feeding system moves the tablets from the hopper to the counting area. Many machines use a vibrating plate or a rotary disc for good separation. The vibration prevents them from piling up. It makes tablets do not stick together. It could spread the tablets evenly and lead them into channels.

Counting sensor

This part detects and counts each tablet as it passes through. Most machines use photoelectric sensors for counting. Some high-speed machines are equipped with more advanced types like laser sensors for better accuracy. The counting sensor should be sensitive enough to make good counting.

In most tablet counters, the sensor is usually placed at the discharge chute or in the middle of the path. Some have many channels and sensors for high-speed counting. This allows the machine to count and fill many bottles at the same time.

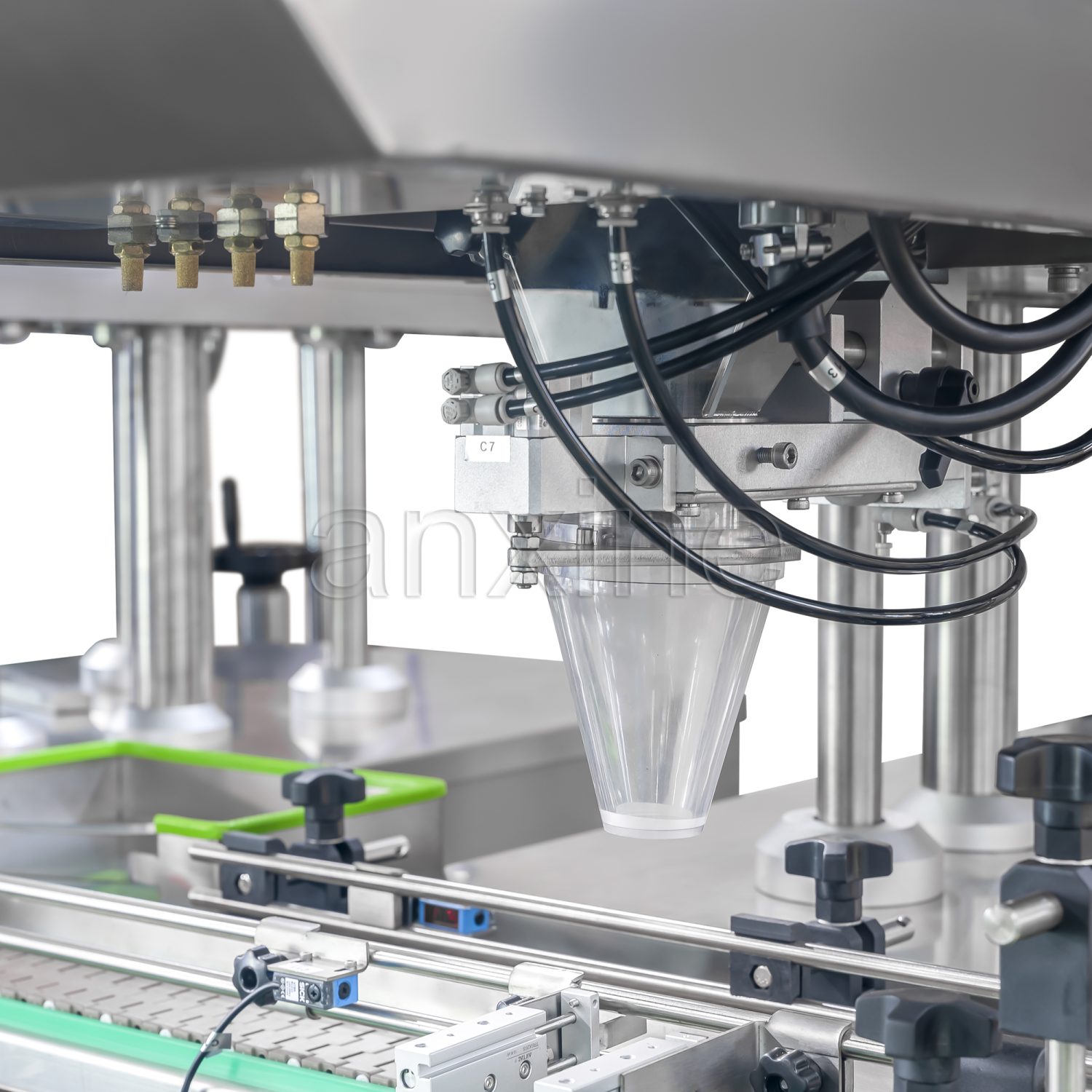

Bottle conveyor system

This system moves empty bottles into right position. It usually uses a belt to transport bottles. It works together with sensors for correct placement. Once a bottle is filled, the conveyor moves it forward and brings in the next empty one. The conveyor must be well-timed with the counting and filling process. So it won’t spills or delays.

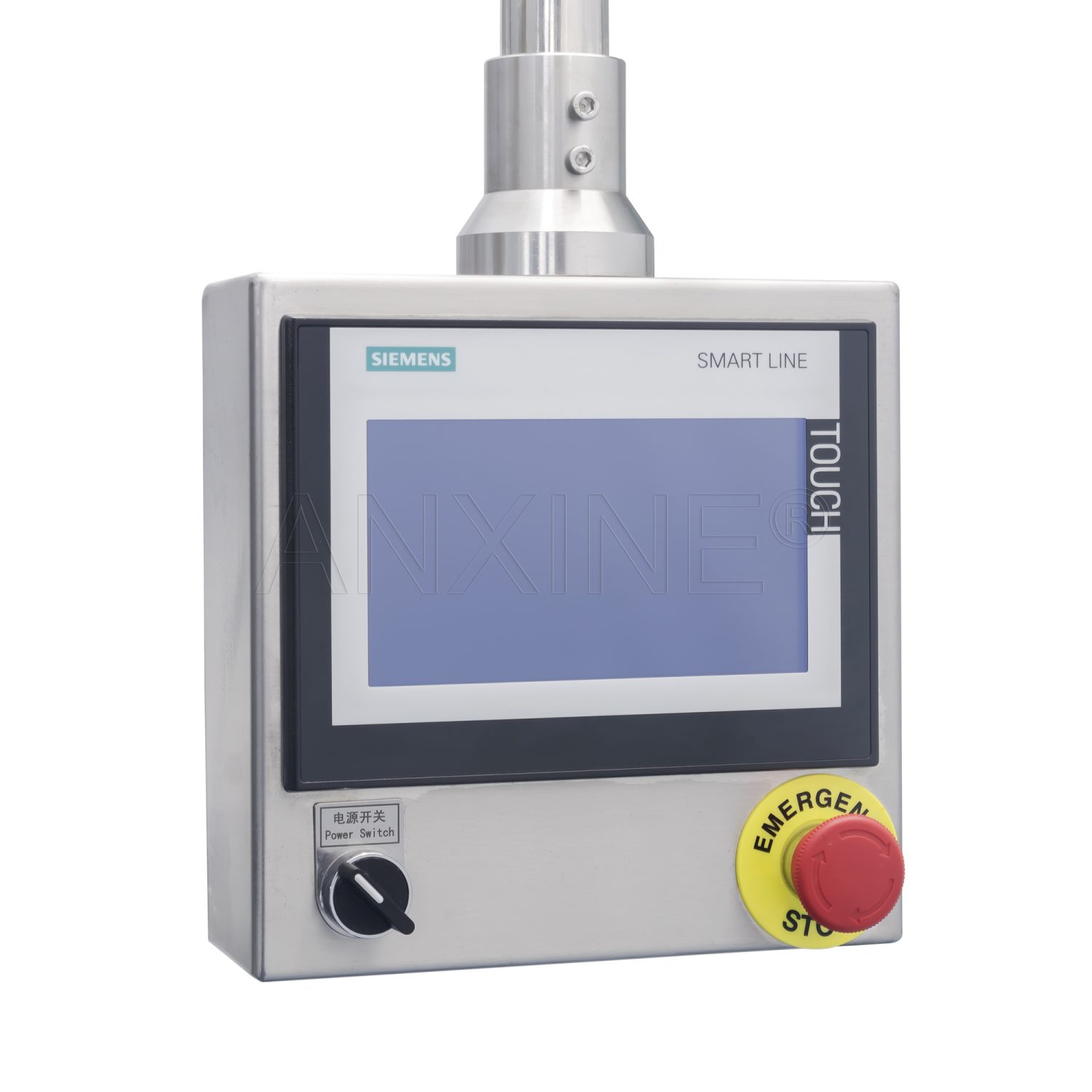

Control panel

This component could be used to set the filling number, adjust the speed, and change settings for different products. It monitors all parts working in real time. Some panels could save settings for different tablet types. This makes the process more efficient during changeover.

Dust collection system

The dust collection system keeps the machine clean. It removes powder and dust during operation. The collection unit usually includes a fan or vacuum. It collects the dust in a container for cleaning. This avoids cross-contamination for product safety.

How does a tablet counter work?

Step 1: Tablets are loaded into the hopper.

At first, the operator pours tablets into the hopper. It feeds the tablets in a steady way. The hopper is usually made of stainless steel to keep the tablets clean and safe.

Step 2: Tablets move to the feeding system.

Next, tablets go into the feeding system. It spreads the tablets out so they don’t overlap. Then each tablet moves forward one by one. This feeding step helps space the tablets properly before counting.

Step 3: Tablets are filled into bottles.

Then, tablets move through the channel with sensors for counting. The machine can count hundreds or thousands of tablets per minute. As the tablets are counted, they fall directly into the empty bottle below. If the required number of tablets is reached, the filling stops and bottles continue to move forward. The next empty bottle moves into place for filling. This process repeats until all the bottles are finished.

Step 4: further processing

Once the bottle is filled with the correct number of tablets, it moves for further processing, like capping and sealing. Many models of tablet counting equipment could be integrated with other machines to finish the whole process.

How to choose a suitable tablet counter for your pharma business?

When you are selecting a tablet counting machine, the following elements need to be considered.

Product volume

The first thing you should think about is how many bottles you need to fill each day. If your production is small, a semi-automatic tablet counter may be enough. It requires more operator work but costs less. If your factory runs large batches and needs high speed, an automatic tablet counting machine is better. It can handle thousands of tablets per hour with little labor. But it costs more.

Great flexibility

Pharmaceutical companies often produce different shapes and sizes of tablets. So you need to make sure the machine can handle round, oval, or irregular tablets. A flexible machine should be equipped with adjustable parts or settings. This will save time during product changeovers.

Budget

Prices can be different because of the machine type, speed, and level of automation. If you have a big budget, you can choose a machine that fits your current and future needs. A machine with good support may cost more at first, but it can last longer and make profits in the future. If your budget is tight, a semi-automatic tablet counter is better. It can be upgraded when you get profits and need to expand product volume.

The end

A good tablet counting machine can improve counting accuracy and speed up production. So a careful selection is key to your tablet business. With a clear understanding of this equipment, you must know how to use it efficiently.