Tablet inspection machines play a key role in solid dose production. They can check appearance, size and color to see if each tablet meets requirements. If tablets are qualified, they will be sent for further processing like packaging. If not, some models can automatically reject the unqualified tablets. As demand for stable quality grows, more pharmaceutical and supplement companies choose tablet inspectors. A good right manufacturer is always highly related to the machine quality. If you want to buy a tablet inspecting equipment, the following manufacturers could be considered.

Proditec

Proditec is a French company founded in 1987. It makes automatic inspection machines for tablets and capsules. Its main products are automated visual inspection equipment. These machines use cameras and laser technology to check shape and surface defects at high speed. The company also offers support services, including installation, training, and ongoing technical assistance.

VISITAB 3

This is s a high-speed inspection machine for tablets, capsules, and softgels. The equipment checks up to 600,000 pieces per hour. Each product passes a full 360-degree inspection. Cameras and laser sensors detect surface and appearance defects. It is also equipped with AI software to identify more than 50 defect types.

Anxine

Anxine is a leading machine manufacturer in China. It also has offices in the US. Their machines are shipped to over 200 countries and regions worldwide. The company mainly makes capsule filling machines, tablet presses, inspection equipment, liquid fillers, etc. The machines are always applied in the pharmaceutical, nutraceutical and food industries. The company holds ISO9001, GMP, and CE certifications to meet strict regulatory requirements. It also offers customer support with a one-year warranty and ongoing technical help.

Moreover, the company offers flexible customization. It allows clients to add or adjust the part to meet specific production needs. You just need to contact the team and tell them your requirements. Then they would make the sample according to your needs. If you are not satisfied, it can be modified until you think it is ok. Shipping service is also provided. The company can directly ship the equipment to your designated place.

KPS-220B

This is a tablet and capsule inspection machine for visual quality checks. It supports tablets, hard capsules, and soft capsules for inspection. The KPS-220B machine rotates products 360 degrees and flips tablets to show both sides for a full check. Adjustable speed could match different inspection needs. In addition, lighting and mirrors reduce blind spots. Operators can remove defective tablets with a vacuum nozzle. The design features easy operation and cleaning. It reduces mix-up and contamination risk.

Accura

This company is based in India and focuses on pharma equipment. The main products include tablet and capsule inspection machines, tablet elevators, label counting equipment, etc. These products help identify defects and improve quality control before packaging. The company mainly serves domestic and global clients with inspection solutions.

NETRA VS6

It is a fully automatic inspection machine for tablets and capsules. It checks product appearance and finds defects during production. The system removes rejected tablets and capsules on its own, so manual inspection is not needed. The machine is designed for continuous operation and stable output. It suits pharmaceutical production lines that need higher inspection speed and consistent quality control.

United Pharmatek

It is a small-scale equipment supplier based in the US. It provides a wide range of processing, packaging, and laboratory machines for pharmaceutical production. The products include tablet inspection equipment, tablet hardness testers, friability testers, etc. They serve customers in pharmaceuticals, nutraceuticals, food, cosmetic, and chemical areas.

TIM-500

This model is a manual inspection machine for tablets. It uses conveyor belts to move and flip tablets for top and bottom checks. Tablets stay stable during inspection. The system supports up to 50 kg per hour and allows easy cleaning.

Key International

It is a U.S. company that makes processing and packaging equipment for the pharmaceutical, nutritional, and chemical industries. Main products include visual inspection machines, tablet testers, blister packers, etc. It also provides spare parts and technical support for clients.

NEW Enclony PLANET EV Series

This equipment is a high-speed automatic visual inspection machine for tablets and capsules. It uses multiple 2D, 3D, and infrared cameras for full surface checks. The equipment could handle many shapes and sizes. It removes dust, rejects defects automatically, and supports fast setup.

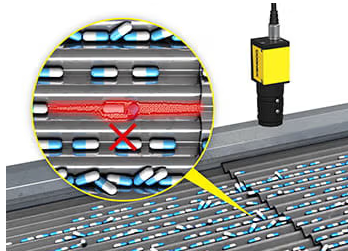

Cognex

It is an American company based in Massachusetts. It makes machine vision systems, vision software, and vision sensors used in factory automation and inspection. These products help manufacturers inspect parts, read codes and guide automation equipment to work. Cognex also offers technical support and training to help customers set up and use its vision tools.

Tablet Inspecting Equipment

It can inspect size, shape, color, surface, and labeling on both sides. The system helps find damaged tablets and foreign material. It reduces manual inspection limits and lowers the risk of recalls and quality issues.

Sensum

This is a European company that develops and makes automatic visual inspection machines. The main products include the SPINE series for inspecting tablets, machines for capsule sorting, and bottle filling. The company also offers process analytical technology tools for real-time monitoring. Besides, Sensum provides customization, and both online and on-site technical support.

SPINE Hypo

SPINE Hypo is designed for safe inspection of highly potent tablets, capsules, and softgels. It uses a contained system to reduce contamination risk. The machine supports dry and wet cleaning, and tool-free operation.

ACG

This company is based in India. It offers equipment for pharmaceutical and nutraceutical production. Its products include packaging films, vision inspection systems, track-and-trace equipment, etc. The company also offers engineering support, equipment installation, and after-sales service. This helps manufacturers keep production running smoothly.

QUALISHIELD TC Series

It is a high-speed inspection machine for tablets and capsules. It uses multi-channel vision systems to check appearance and surface defects. The machine suits continuous production lines with different output needs.

Pharma Technology

It is a Belgian company that makes inspection equipment for tablets and capsules. It also has service locations in Germany, North America, and the Asia-Pacific region. Pharma Technology makes tablet and capsule handling equipment such as dedusters, polishers, visual inspection equipment, etc. It also provides installation, maintenance, spare parts supply and operator training.

T/CVIS-NSR

This model can handle up to 300,000 tablets or 125,000 capsules per hour. It uses cameras to check for defects or other issues with embossing or lettering. The equipment supports a wide range of product sizes and allows easy changeover.

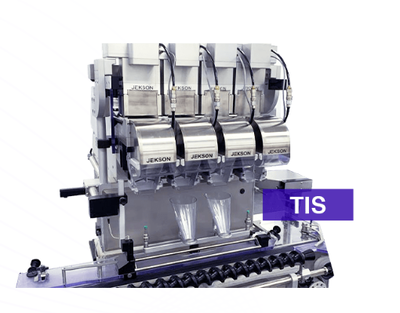

Jekson Vision

Jekson Vision builds machine vision inspection and track-and-trace systems for industries such as pharmaceuticals and packaging. Their equipment inspects tablets, capsules, blisters, labels, codes, and bottles. The machines use cameras and software to check product quality automatically. Many of them also include AI-driven vision inspection and software tools for traceability.

TIS

This tablet inspection machine uses a vision system to check size, color, shape, and defects at high speed. It inspects 100% of tablets and stops automatically when problems appear. The machine supports multiple channels and different tablet types for check.

How to Choose a Good Equipment Supplier for Your Tablet Inspection?

A reliable supplier is important for further operation. It guarantees a smooth and efficient production when problems occur. The following tips may be helpful about how to select an ideal one.

Experience

A good supplier has real experience with tablet inspection machines. He understands common troubleshooting tips, such as dust issues. The more experience the manufacturer has, the more efficiently your issues are solved. In addition, an experienced manufacturer can give you practical advice when you want to adjust the machine design.

Flexible Customization

If you want to customize some parts for better production, you need to check it with your supplier at first. If he can’t meet your needs, you still have time to find a new one. Simple changes like camera setup or software reports should be easy to adjust. For complex customization, you can ask their former sample to see if they are reliable.

Compliance Support

Inspection equipment must meet regulatory requirements before it can be used in production. Compliance support means the supplier understands these rules and can help prepare needed documents. Common standards include IQ, OQ, and PQ documents. IQ confirms the machine is installed correctly. OQ checks that it works as expected under set conditions. PQ shows stable performance during real production. These documents are often requested by QA and regulatory auditors

This support also includes system rules such as 21 CFR Part 11 and data integrity. These rules control user access, record changes, and data storage. They help make inspection data clear, traceable, and reliable.

After-sale Service

Problems can stop the whole line. A good supplier offers clear after-sales support and a fast response. When you need help, the supplier can quickly solve your problems, such as part replacement. It reduces your production delay and loss. Clear and in-time communication after purchase also helps improve your production efficiency.