Inspection is a step that should never be overlooked in pharma manufacturing. Even if your tablets and capsules look fine coming off the press or filler, some defects are easy to miss at first glance. Not to mention visible issues like dents, chips, or dark spots. If you catch them too late, they can undo weeks of production and lead to batch holds, investigations, or even a full rework.

That is exactly where a tablet and capsule inspection machine becomes indispensable. In this article, we’ll explore what the inspection equipment really does, the main types out there, how the inspection process flows by type, and how to pick a system for your line.

What Can a Tablet and Capsule Inspection Machine Actually Do?

A tablet and capsule inspection machine is used to check every pill for defects or contamination before it goes to packaging. In most automatic setups, the machine can also remove faulty units right away. So the inspection here includes two jobs running together: Detection and Rejection.

👉 Tablet and capsule defects the machine can spot:

| Category | Tablet Defects | Capsule Defects |

|---|---|---|

| Visible issues | Capping, lamination, chipping, cracking, binding, picking, mottling, orange peel, black spots, dirt, double impression, engraving defects, misprints | Dents, crushed shells, split caps/bodies, telescoped, missing caps/bodies, damaged band, smudged print |

| Hidden contamination | Foreign particles, metal fragments, dirt, bits, plastic | Metal fragments, bits, hair, plastic, dust |

| Dosage accuracy | Inconsistent thickness, uneven weight | Empty capsules, overfilled, underfilled |

Some tablet and capsule inspection systems stand alone for small batches. Most modern models can also integrate with your tablet press, capsule filler, or downstream packaging equipment.

But no matter the setup, a solid tablet and capsule inspection machine can:

- Protect patient safety by keeping contaminated or sub-potent products out of the market

- Reduce manual, bare-hand inspection time and labor cost

- Cut waste by catching defects before bottling or blister packaging, and lower the risk of expensive recalls

- Help meet strict regulatory compliance with cGMP and guidelines associated with FDA and EMA expectations

Types of Tablet and Capsule Inspection Machine Solutions

Like we talked about earlier, a tablet and capsule inspection machine can catch visible defects, “hard-to-see” defects, or both. It all depends on how the system is configured. That’s why tablet and capsule inspection machines don’t all look the same. To make things easier, let’s sort them into two big categories based on the defect type:

For Identifying Visible Defects

Roller Inspection Machine

This is the classic semi-automatic inspection system. It assists human inspectors by presenting each tablet or capsule for easy viewing. Because the unit is built in a table-style, it’s often called a roller inspection table.

Key components you’ll usually see:

- Hopper: Holds the tablets or capsules to be inspected. Equipped with an adjustable feed gate to control product flow.

- Vibratory chute: Uses gentle vibration to spread the pills into a single layer and feed them into the inspection area.

- Inspection rollers: Clear rollers, often Lexan or silicone-coated. Rotate the tablet or capsule to expose all sides for viewing.

- Conveyor belt: Built from the rollers. Transfers accepted products to the discharge chute.

- Inspection lighting: Bright, adjustable LED lights to make defects easier to catch.

- Adjustable mirror: Gives you a better view of the far side of the product without moving.

- Manual removal system: Includes a foot pedal and a handheld vacuum wand. The foot pedal stops the roller conveyor. The vacuum wand picks out the defective item.

How the roller inspection table works:

When tablets or capsules flow out of the hopper, the vibratory chute vibrates to separate them. The products move forward onto the rollers.

The rotating rollers expose all sides of the products. Lighting and mirrors give a much clearer view of each pill for the operator to check.

Once a defect is spotted, the operator steps on the foot pedal to pause the roller conveyor. Then, use the vacuum wand to remove the defective unit. Good products keep going to the collection area.

Practical watch-outs:

- Results depend a lot on the operator’s focus and skills.

- Repetitive inspection work can cause operator fatigue.

- Throughput is lower than that of automatic inspection.

- Defect standards must be clearly defined for every operator.

- Lighting and belt speed need to be tuned so the operator can keep pace.

- The human eye can miss subtle defects. That means this setup can’t ensure 100% perfect outcome.

Tablet and Capsule Visual Inspection Machine

Want faster inspection and fewer false rejects? Automated optical systems are often the way to go. Instead of the human eye, automatic tablet and capsule inspection machines use high-speed cameras and 3D laser scanning to find defects. That makes inspection quicker and more precise.

Critical parts usually include:

- Inspection track: A rotating drum or a dial plate. Comes with pockets to carry pills. Has a special mechanism to flip or spin the product.

- High-speed cameras: Capture each unit at high frame rates.

- 3D lasers (optional): Measure shape profile to catch defects invisible to 2D systems.

- Lighting module: Provides multi-angle illumination to reveal tiny flaws.

- Software + algorithms: Run pass/fail logic and mark defects.

- Reject mechanism: Uses an air jet, flap gate, or vacuum to remove bad units.

How the automated optical system operates:

When fed into the machine, tablets or capsules fall into the pockets of the rotating drum or dial plate. The mechanism spins or flips these pills.

As each unit zips by, the cameras take dozens of photos in multi-angle lighting. If the system also includes 3D scanning, it will measure the surface profile.

The machine then uses software to instantly analyze the images and mark the defective items. Then, it triggers the rejection system. Good products go to another outlet.

Key considerations:

- Watch for powder buildup on camera lenses. That can lead to missed defects or false rejects.

- Set defect thresholds and rules carefully. Overly strict standards can reject good products for minor marks.

- Wrong lighting can create glare on shiny capsules and hide real surface damage from the cameras.

- The system usually needs re-training when you switch to a new product.

For Spotting Hidden Hazards

Metal Detector

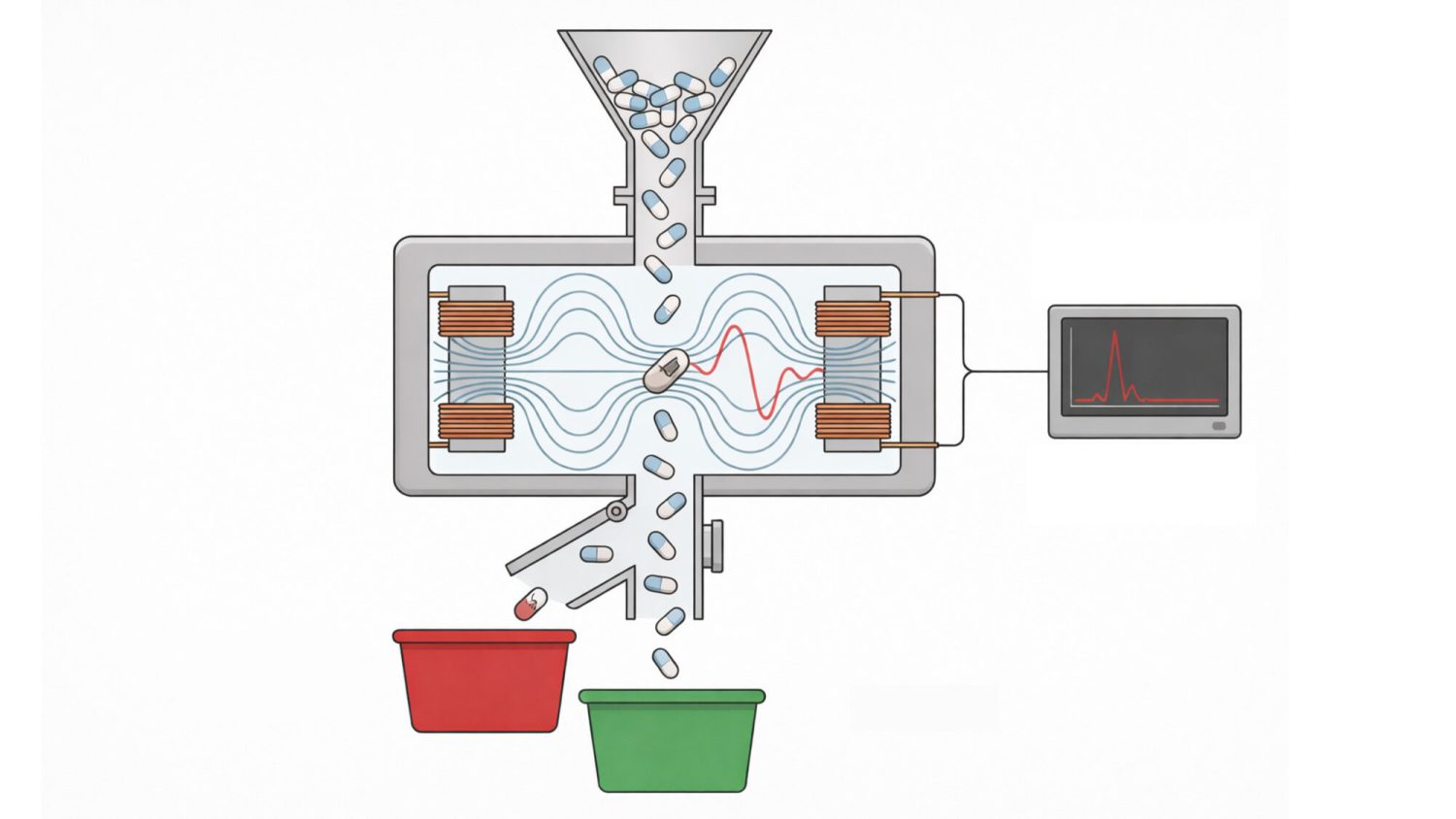

This metal detector focuses on metal contamination that you can’t see from the outside of tablets or capsules. It also has versions that can find small metal fragments in packaged products. This type of tablet and capsule inspection machine uses coils to generate an electromagnetic field to catch defects.

What’s inside this inspection machine:

- Transport system: A chute for gravity fall or a conveyor belt for packages.

- Detector head or tunnel: The aperture that lets the product pass through for inspection.

- Coil system: Located inside the head or tunnel. Usually contains one transmitter coil and two receiver coils.

- Reject device: Diverter flap, air blast, or drop chute.

How the detector works:

Products pass through the chute or tunnel. The coil system generates an electromagnetic field inside the aperture.

When a metal particle passes through the field and interacts with it, the machine’s electronics detect the interaction as a signal and trigger the reject system. Then, the reject device removes the contaminated pill or package.

Real-world best practices:

- Power lines and nearby electronics can create signals that interfere with the detector’s magnetic field. That may trigger false rejects. So, place the detector a safe distance away from these interference sources.

- If your detector is triggering for no reason, look at the environment. Vibration from surrounding machines can weaken the signal and cause false alarms. Static buildup can do the same, so grounding and static control measures are often needed.

- Stainless steel used in pharma equipment is weakly magnetic and not very conductive. It’s even harder to detect than ferrous metals. So consider the limitation when setting the detector’s sensitivity.

X-ray Inspection System

Compared to pharmaceutical metal detectors, X-ray is a more versatile inspection option. The system is not limited to metal. It can detect various foreign objects like bits of glass, stone, hard plastic, or rubber.

These inspection machines use X-rays to penetrate the target and image what’s inside. For example, an internal pill crack, an underfilled capsule, or a missing tablet in a blister pack can all be flagged by the system.

Core parts:

- Conveyor: Moves product through the X-ray beam.

- X-ray generator: Produces the X-ray beam.

- Detector: Captures the X-rays that pass through the product and creates a digital image.

- Image processing software: Analyzes the image and decides pass or fail.

- Safety features: Shielding and interlocks that prevent X-ray leakage and protect operator safety.

Basic principle of X-ray systems:

Tablets or capsules move on a belt through a shielded area. A low-energy X-ray beam goes through the product.

The detector captures an image instantly. The system turns that beam information into a grayscale image.

- Less dense areas look lighter

- More dense areas look darker

The software analyzes the image in real time. It compares each image to preset rules. The machine kicks out the suspect item automatically.

Limitations you should know:

- X-rays only detect what looks different in density, so contaminants with a similar density to the product can slip through.

- X-rays cannot spot very thin pieces.

- If tablets or capsules overlap, the sensitivity drops.

- Size, thickness, and fill density change what the system can reliably detect.

- The X-ray beam is dangerous, so stricter access/maintenance procedures are required.

Checkweigher

Rather than catching defects, checkweighers perform another tablet and capsule quality inspection. They’re all about dosage and weight accuracy. They can also be configured for individual units or finished packs.

A checkweigher is a precision scale system. It can verify whether capsules are empty or tablets are too heavy. Any unit outside the tolerance is flagged and removed from the line. This helps keep dosage uniform across the batch.

Checkweighers are also widely used to weigh a fully loaded bottle, blister pack, or carton. The system can tell if a tablet or capsule is missing. In practice, many production lines include a checkweigher after filling/sealing.

How a checkweigher works and its key components

- Step 1: Tablets or capsules are placed into a parts feeder. This component feeds each unit into an individual lane.

- Step 2: The handling mechanism transfers each product into the weighing system.

- Step 3: Each unit is isolated for its own measurement.

- Step 4: The system automatically compares the measured weight against preset parameters to determine if the product is within the acceptable range.

- Step 5: Based on the weight results, the rejector system sorts the products into three categories: good, overweight, and underweight.

Main constraints to be aware of

- Checkweighers cannot find contaminants because they only check weight.

- Weight ≠ Dose for every product, so the weighing technology is not a guarantee for uniform API content.

- Vibration may reduce accuracy, especially at higher speeds.

- Products must be properly spaced, or the system can give false readings.

- Very light units are harder to weigh precisely.

Regulatory Considerations for Tablet and Capsule Inspection Machines

Before choosing a tablet and capsule inspection machine, here are some key regulatory points you should know:

GMP and qualification

If your inspection systems operate in the US, it falls under 21 CFR Part 210 and 211. In Europe, they are managed by EudraLex Volume 4. They should also align with ICH Q8, Q9, and Q10. These are a modern framework for pharmaceutical quality.

That means the machine you choose should include:

- Written SOPs for setup, operation, cleaning, and maintenance.

- Clear defect limits and reject criteria.

- Formal qualification (DQ, IQ, OQ, PQ) as outlined in EU GMP Annex 15.

Camera- or vision-based systems also need challenge tests. These tests prove the machine can reliably detect the defects it claims to catch.

Data integrity and electronic records

Although we didn’t specify it earlier, most of the inspection systems we mentioned are computerized. This means they must comply with EU GMP Annex 11 and 21 CFR Part 11.

Check whether your tablet and capsule inspection machine offers:

- Unique user logins and role-based access.

- Secure audit trails for recipe and parameter changes.

- Records that follow ALCOA+ principles (attributable, legible, contemporaneous, original, accurate, plus complete, consistent, enduring, available).

Type-Specific Compliance

Roller inspection table: This type of machine still relies on the human eye. So the system should come with clear instructions for installation, setup, cleaning, and maintenance.

Automated visual inspection machine: These computer systems need to be validated to prove they work correctly. And if they create or store electronic records, they must meet 21 CFR Part 11 regarding digital records and signatures.

Metal detector: This is the last physical checkpoint for metal contamination before the product reaches the patient. It should be managed as a critical control point (CCP) to prevent contamination.

X-ray Inspection system: Worker safety is the first concern with X-ray inspection. So the system has to meet certain radiation safety requirements. In the US, X-ray systems must follow FDA 21 CFR 1020.40 and OSHA 29 CFR 1910.1096.

Checkweigher: To make sure patients get the right dose, your checkweigher should deliver reliable, repeatable weight readings. In practice, it should meet standards like NIST Handbook 44 and USP <905>.

How to Choose a Tablet and Capsule Inspection Machine

Selecting the right inspection system ensures pharma products are safe and meet high standards. Not sure where to start? These tips might give you some ideas:

- Start with your defect list: Decide if you need to find metal fragments, visual defects, or empty capsules.

- Look for flexibility: Choose a machine that switches quickly between different product formats. Some models only need a fast tooling change to inspect different tablets or capsules.

- Check the speed: The machine should match your production rate to avoid bottlenecks. If you’re handling large volumes, automatic systems are faster and help cut labor and rework.

- Plan your space: Make sure the unit fits your floor and connects easily to existing equipment.

- Verify vendor support: Pick a supplier that offers training, spare parts, and required safety documents.

Final Word

This guide may not cover everything in detail. So if you have any questions or want to know more about tablet and capsule inspection machines, you’re always welcome to reach out to our team at Anxine. We’re here 24/7 to help you solve tablet and capsule quality inspection headaches.