Blister packaging is everywhere in daily life. From medicines to medical devices and consumer goods, blister packaging keeps products safe and clean. Because of these practical benefits, many industries rely on blister packaging for product protection. A clear understanding of its applications helps you choose the right type for your products.

What is blister packaging?

This is a popular packaging method to pack a single product in one cavity. The number of cavities could be customized to meet specific production needs. A flat layer is sealed on the back for protection. This structure keeps the product clean, protected, and easy to use. When a user needs one piece, they just need to peel the package to take it out. This helps consumers get the number of products quickly and easily. It is especially important for medicines.

Blister packaging comes in 3 common types.

- Push-through blisters are the most popular. The user presses the product through a thin foil layer to open it.

- Peelable blisters open by peeling the back layer. This method is easier for people with weak hands.

- Cold-form blisters use aluminum instead of clear plastic. They offer stronger protection from air and moisture.

Advantages of blister packaging

The biggest benefit of blister packaging is the unit-dose control and easy use. Each dose stays separate and clean. The pack also helps people see the product clearly when the blister is made of transparent plastic. It is helpful to check the color, shape, or size. Moreover, blister sheets are light, flat, and firm. They fit well in boxes and do not take up much space. This is greatly convenient for shipping and storage.

Blister Packaging applications in pharmaceuticals

Blister packs are widely used for solid medicines like tablets and capsules. They are the most popular type for medicine packaging. Both prescription drugs and over-the-counter (OTC) products often come in blister packs. The sealed pockets protect the product during shipping and daily use. The format also supports clear labeling, making it easier for users to follow instructions.

In addition, some blister packs come with added safety features. For example, child-resistant designs make it harder for young children to open the medicine. Tamper-evident layers show clear signs if the pack has been opened or damaged. It helps protect user safety and product integrity.

Common uses in medical products

Medical devices

Many small medical devices use blister packs to stay clean and safe before use. They are always applied on items such as lancets, small surgical tools, dental tips, or wound-care accessories. The clear plastic film has good visibility and protection from dust, germs, and moisture.

Syringes and test kits

Blister packs are common for pre-filled or empty syringes. The pack protects the syringe barrel and needle from damage during transport. It also helps keep the product sterile until the use. Many rapid test kits, such as blood glucose strips or pregnancy test parts, also use blister packaging. The packaging makes the kit simple to handle and reduces the risk of contamination.

Diagnostic products

Diagnostics need clean and stable conditions. Blister packs could hold products like reagent strips, small sample containers, and rapid diagnostic parts. It supports long shelf life and avoids exposing the rest when taking out one.

Blister packaging applications in consumer goods

Many daily-use goods also need blister packaging. Here are some examples.

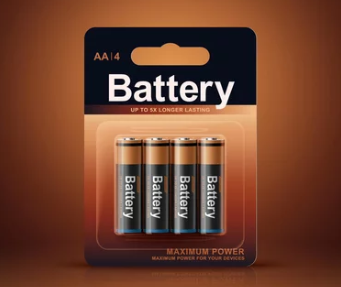

- Batteries. The pack could stop the metal parts from touching other items during transport. It also allows customers to check if the size and type meet their requirements.

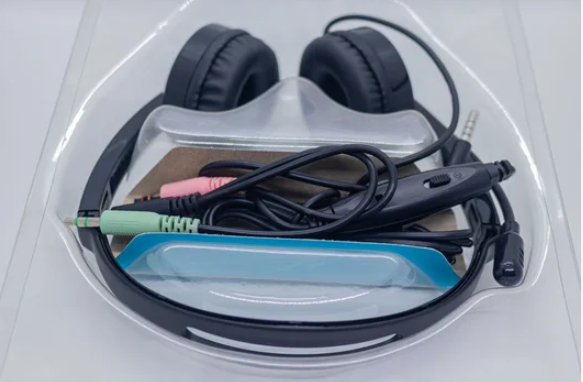

- Small electronic parts. USB adapters, earbud tips, memory cards, and spare screws often come in blister packs. The pack holds each item in place so it does not shift or fall out.

- Personal care products. Toothbrushes, razors, nail tools, and small beauty accessories use blister packaging. The pack keeps the item hygienic and protected from dust.

Blister packaging uses in food and nutraceuticals

Many supplement brands use blister packs to keep each tablet or capsule dry and clean. Each cavity protects the product from air and moisture. It helps maintain strength and flavor, like probiotics, lozenges and candies. This type of pack also helps customers track daily consumption.

Some small food items, such as gum and mints, are also packed in blister packs. The clear cover shows the product directly, and the sealed pockets help control freshness.

Common applications in sports and fitness products

Blister packaging also appears in many sports and fitness items.

- Small accessories. Items such as wristbands, grip tapes, mouthguards, and replacement parts often need blister packs. The pack keeps each item in place and avoids loss or damage.

- Fitness trackers and small devices. Compact gadgets like step counters or heart-rate sensors use blister packaging. It could prevent scratches and give customers a clear view of the device before buying.

How will blister packaging develop in the future?

According to Yahoo Finance, the global plastic blister packs market is valued at around USD 11.66 billion in 2025. It will reach nearly USD 19.91 billion by 2034–2035. Key market trends include strong demand for unit-dose, tamper-evident packaging, and robust protection against environmental factors. These features are especially important in pharmaceutical and healthcare applications.

At the same time, consumers have an increasing demand for sustainable materials. Therefore, more blister packaging companies choose recyclable or lower-impact materials. Some producers are testing new barrier films and smart features to help control tampering or counterfeiting. It is evident that a producer who adapts to these needs stays competitive in the long run.

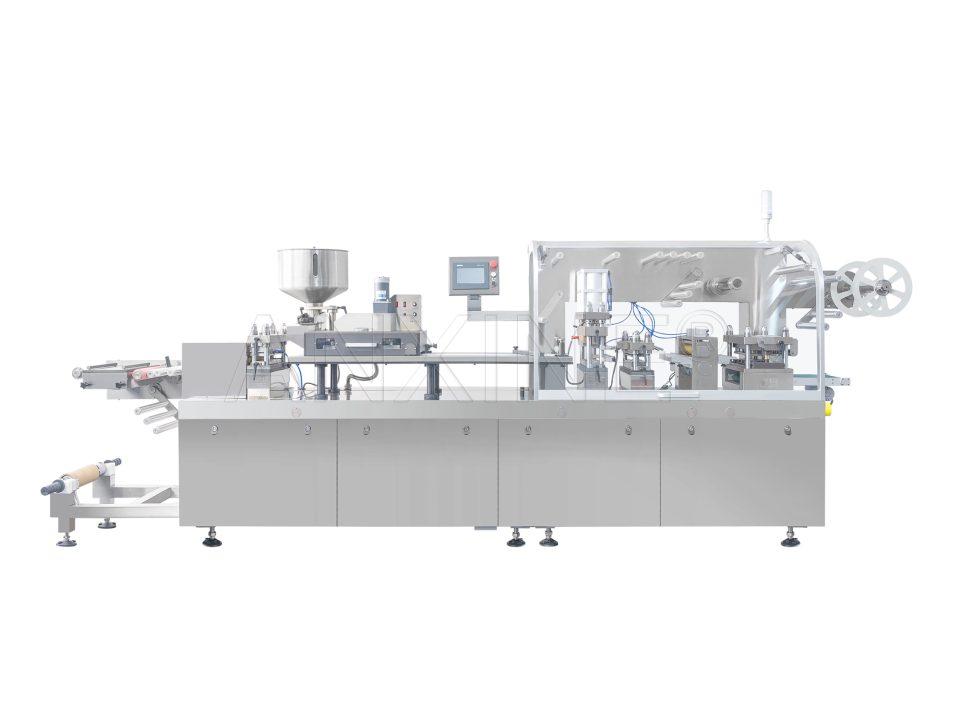

Cooperate with Anxine to get efficient equipment for blister packaging

Good packaging also requires high-quality equipment. If you wonder how to choose from so many suppliers, Anxine is your good partner. We have years of experience with different machines for the pharma, nutrient or food areas. We manufacture various types of blister packaging equipment, capsule fillers, tablet presses, liquid fillers, etc. Customization is also supported. You just need to tell us your requirements and see if the sample meets your needs. If not, we would modify it until you are satisfied.

Besides, we provide comprehensive after-sale support. If you find trouble during the operation, our technical team could go directly to your factory to solve problems. If one machine part is broken, we also offer free replacement and send it to you at no cost. Feel free to contact us now.