You’ve just pulled a late shift to finish a big batch of tablets. And suddenly, they start chipping in the coating pan. Or worse, they crack as soon as you run the blister machine. That’s the kind of headache no one wants.

All of this comes back to one thing: the hardness of your tablets. It might sound very technical, but it simply means how tough your tablets need to be to survive manufacturing, packaging, and even shipping.

In this guide, we’ll go over the key facts about tablet hardness and show you how to dial it in so your tablets stay intact throughout the manufacturing process.

What Is Tablet Hardness and Why Does It Matter?

Tablet hardness is just a way of saying how much pressure it takes to break or crush a tablet. You will also see terms like breaking force, crushing strength, or diametral compression strength. Technically, those are more accurate. But in everyday pharma production, people still prefer saying “tablet hardness”.

A tablet should be hard but still friable. That brings up another term: friability, which describes how easily a tablet chips or breaks under normal handling. Hardness and friability are different concepts, but both are crucial measures of a tablet’s mechanical strength.

Now, let’s circle back. Why is tablet hardness important? Because:

It affects tablet friability. As mentioned earlier, these two measurements are closely connected. That means a harder or softer tablet crumbles less or more. So, only getting the hardness right helps keep the balance and gives you pills that stay intact.

It may lead to trouble during coating. Most tablets need to be coated for different purposes. They have to tumble in the coating pan to get that layer on. If your tablets are too weak, they’re likely to chip, laminate, or erode during this step.

It also affects how the medicine works. If your tablets are too hard, they may not break down in the body on time. That can slow the onset of action. Too soft tablets could crumble easily, which can be dangerous, especially for the enteric-coated ones.

Key Factors That Control the Hardness of Tablets

If tablet hardness is off, it is usually not one single reason. It can be a mix of several factors working together. So, what should you be looking at?

1. Formulation Choices

Tablets are mainly made up of APIs and excipients. The way you choose and balance these ingredients will directly affect the hardness of tablets.

- API properties

Particle size, shape, amount, and compressibility of the powder will affect how well the particles stick to each other during compression.

- Binders

More binder generally makes tablets harder. But too much can slow disintegration and dissolution. The binder type matters too. A strong binder like PVP or HPMC will behave very differently from a weaker one.

- Fillers and diluents

- Lactose often gives good compaction and clean tablets.

- Microcrystalline cellulose (MCC) is very plastic, so it gives high hardness but can make tablets very dense.

- Dicalcium phosphate is more brittle and may need higher compression forces.

- Lubricants and glidants

Magnesium stearate is great for ejection, but too much can coat particles and reduce bonding. This can lower tablet hardness and make them more friable.

- Moisture content

Adequate moisture can actually help particles bond better. But too much or too little may weaken your tablets.

2. Blending Process

How the ingredients are blended often has a direct impact on tablet hardness.

- Lubrication issues

When you blend in too much lubricant, the particles get over-lubricated, and the result is usually softer tablets than you intended.

- Blender type

Powder blender choice matters. Even if you set up the same parameters, different blender types can still produce very different blends. This can lead to noticeable differences in tablet hardness.

- Process parameters

Even slight adjustments to fill level, rotation rate, or blend time can change the way the powder flows and mixes. And that outcome can show up later in the hardness of your tablets.

3. Granulation

Granulation also plays a big role in whether your tablets end up harder or softer.

Granulation technique: Wet granulation often produces granules that compress well, so you typically get harder tablets. When you use dry granulation or direct compression, the tablets may come out a bit softer.

Granule size: Tablets composed of larger granules are usually softer and more friable. That’s because these particles have fewer contact points per unit volume. It offers less surface area for them to bond. Smaller granules pack and bond better, so they often give harder tablets. But if the particles are too fine, flow becomes a problem.

4. Tablet Press Settings

Your tablet press also has a huge impact on the hardness of tablets, even when you don’t change the formula at all. Here are a few key parameters you should pay attention to:

a. Compression force

This is the pressure your tablet press applies when forming the tablets. Generally, more force = harder tablet. If you increase the compression force, tablets get denser and stronger. But if you overdo it, you might see problems like capping or lamination.

b. Dwell time and turret speed

They refer to how long the pressure is applied and how fast the press runs. As turret speed increases, dwell time shortens. In that case, the powder has less time to compact, so hardness may drop.

c. Precompression

Precompression is a small initial force applied before the final press. It’s usually 10-30% of the main force. This step squeezes out tapered air from particles and gently packs them. All of this helps deliver stronger, harder tablets.

5. Tooling and Tablet Design

You can have the right recipe and the right press settings, but there are still other details you can’t ignore:

Punch and die: When you use deep cup punches or very bold embossing, you’re more likely to create weaker spots on the tablet. Those areas are the first to chip or crack. And worn tablet press tooling can make tablets inconsistent.

Tablet thickness and size: Very thin tablets are often more fragile. Larger tablets generally need more compression force to be hard enough. That means you have to pay closer attention to the settings.

Tablet Hardness Units You Should Know

When we measure tablet hardness, we’re measuring force. The common units are:

- Newtons (N): the SI unit of force

- Kilogram-force (kgf): a gravitational metric unit of force

- Kilopond (kp): a force exerted by one kilogram under standard gravity, about 9.8 N

- Kilogram (kg): a measure of the breaking force

- Pounds (lb): more common in the US

You can remember these hardness units this way:

| 9.8 N ≈ 1 kgf = 1 kp ≈ 2.2 lb |

Acceptable Range of Tablet Hardness

So what’s a “normal” hardness for a tablet? A common rule of thumb is about 4-10 kp, or roughly 40-100 N, for most solid oral tablets. Of course, different tablet types have different hardness levels:

- Immediate-release tablets: Roughly 4-8 kp (40-80 N).

- Delayed- or extended-release tablets: Around 8-10 kp (80-100 N). They usually need to be higher to control the release.

- Chewable or orally disintegrating tablets: Often around 2-3 kp (20-30 N). They should be soft enough to bite and break down in the mouth.

- Effervescent tablets: Usually 4-8 kp (40-80 N). These are larger and more fragile.

- Supplement tablets: A common target is 40–80 N. They’re often similar to many OTC pills.

How to Measure Tablet Hardness

Common Types of Tablet Hardness Testers

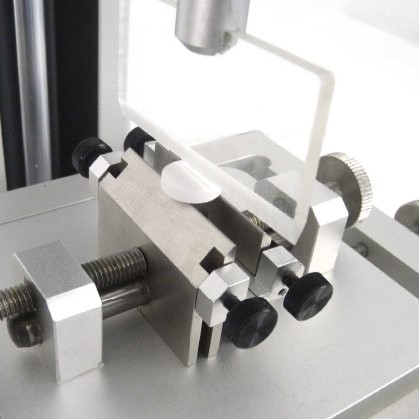

Manual Testers: These are simple handheld devices, like the old Monsanto or Pfizer testers. You place one tablet at a time, squeeze a handle or spring to break the tablet, and read the value. These testers are low-tech but can give quick checks.

Automated Testers: Most modern labs use electronic testers. Some advanced versions can even integrate into production lines. They automatically record measurements. And these testers are not just for hardness now. Many models can measure multiple tablet parameters in one go.

Tablet Hardness Testing Methods

| Test Name | Description | How To Do | |

| 1. Crush (Compression) Test | A standard method. Checking the tablet’s tensile strength across its diameter. | Place the tablet on its edge or side. Apply force to compress until it fractures. |  |

| 2. Three-Point Bending Test | Used mainly for caplets or very large tablets. Measuring bending strength. | Position the tablet on two supports. Apply force in the middle to bend the tablet until it snaps. |  |

| 3. Fracture Test | Testing the tablet’s resistance to compression. | Load a tablet under a spherical-tipped probe. Press the probe into the tablet to crack it. |  |

Quick FAQs About Tablet Hardness

Q1: Which tablet hardness units should I use on my reports?

A: Newton (N) is the SI unit and is now globally used. Kp or kgf are still common. If your historical data are based on them, that’s fine to keep using them.

Q2: What is a typical tablet hardness range for standard tablets?

A: The hardness of many immediate-release tablets is between 40 and 100 N. But the specific value depends on the tablet design and coating.

Q3: How often should I run a tablet hardness test?

A: Run a test once your tablet press is set up. Then check every 15–30 minutes during compression. If you change the formula or adjust the tooling, test again. And then do one last check before packaging.

Q4: Can I fix tablet hardness problems just by changing tablet press settings?

A: Sometimes, yes. If the hardness is already close to your target, adjusting the press is a good first step. But if that doesn’t work, you’ll need to review other factors that we mentioned above.

Q5: Why do my tablets pass hardness tests but still chip during packaging?

A: Hardness alone does not mean your tablets are tough enough. You should also check friability, tablet shape, embossing, and even the environmental conditions.