You have a solid tablet formula, compression is stable, and hardness looks good. Then you run coating. The batch comes out with patchy color, tablets stuck in pairs, and a finish that looks nothing like your marketing photos.

Coating problems like this are very common. In many cases, the issue is not just the recipe. It is how your coating pan is set up and how well you control the pan coating process.

In this guide, we’ll refresh your understanding of coating pans, share what you should pay attention to in your coating process, and show you how to keep your coating pan in top shape.

What Is a Coating Pan?

A coating pan, also called a pan coater, is a machine used to coat tablets, pills, and sometimes even capsules with a thin layer of material. In simple terms, it’s a rotating drum where the product tumbles, is sprayed with a sugar or polymer-based coating, and then dried using hot air. Finally, you’ll get tablets with a smooth, uniform finish.

So, where does a tablet coating machine sit in a tablet production line?

It typically looks like this:

Vibro Sifter → Bin Blender → High-Shear Granulator → Tablet Press → Tablet Deduster → Metal Detector → Coating Pan → Blister Packaging Machine / Bottle Filling Machine

In pharmaceutical and nutraceutical production, a coating pan is mainly used to:

- Build sugar coatings for traditional shiny tablets and some confectionery

- Apply film coatings to protect the core, mask taste, and add color

- Apply enteric or functional coatings for delayed or modified release

Main Types of Coating Pans and How They Differ

Over the years, coating pans have evolved from simple candy-maker style pans to fully automated coaters. Broadly, we can group coating pans in two ways: by their pan design and by the coating methods they support. Here we’ll focus on the two main pan designs you’re most likely to use.

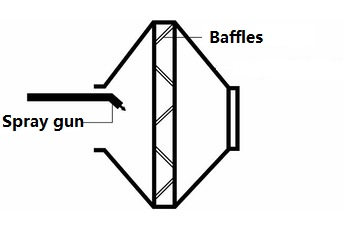

1. Standard Coating Pan

This is the traditional pan coater. It looks like a large metal bowl mounted at an angle. The classic, old-school design was already well-established by the mid-20th century for sugar coating and early film coating. And you’ll still find it running in many plants today.

In the image above, you can see an example. The coating pan is basically a round vessel tilted at about 30-45 degrees. In real-life productions, pan diameters can range from 6 inches to 80 inches to cover different batch sizes.

Because these pans are just simple open drums, they’re not very efficient for drying. That’s why, over the years, people have added clever tricks to standard pans to dry coatings faster, like:

| 1. Pellegrini pan system | Adds baffles inside the pan to flip tablets so hot air can spread more evenly through the bed. |  |

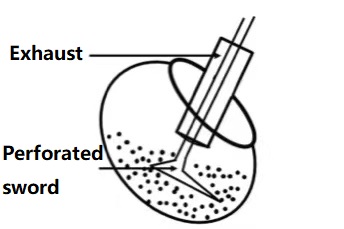

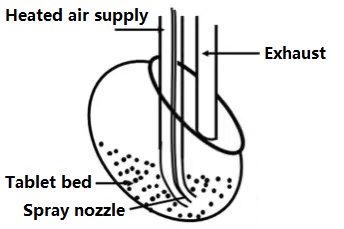

| 2. Immersion sword system | Places a perforated metal sword in the tablet bed to let heated air in. |  |

| 3. Immersion tube system | Inserts a tube, usually fitted with a spray nozzle at the end, into the tablet bed to blow heated air straight into the batch. |  |

Pros and Cons of Standard Coating Pans

- Pros

- Easier to operate and maintain due to the simple structure

- More affordable compared with other pan coaters

- Robust for basic sugar coating and simple film coating jobs

- Cons

- Less efficient drying, so pan coating cycles can take longer

- More sensitive to process parameters

- Require more hands-on attention

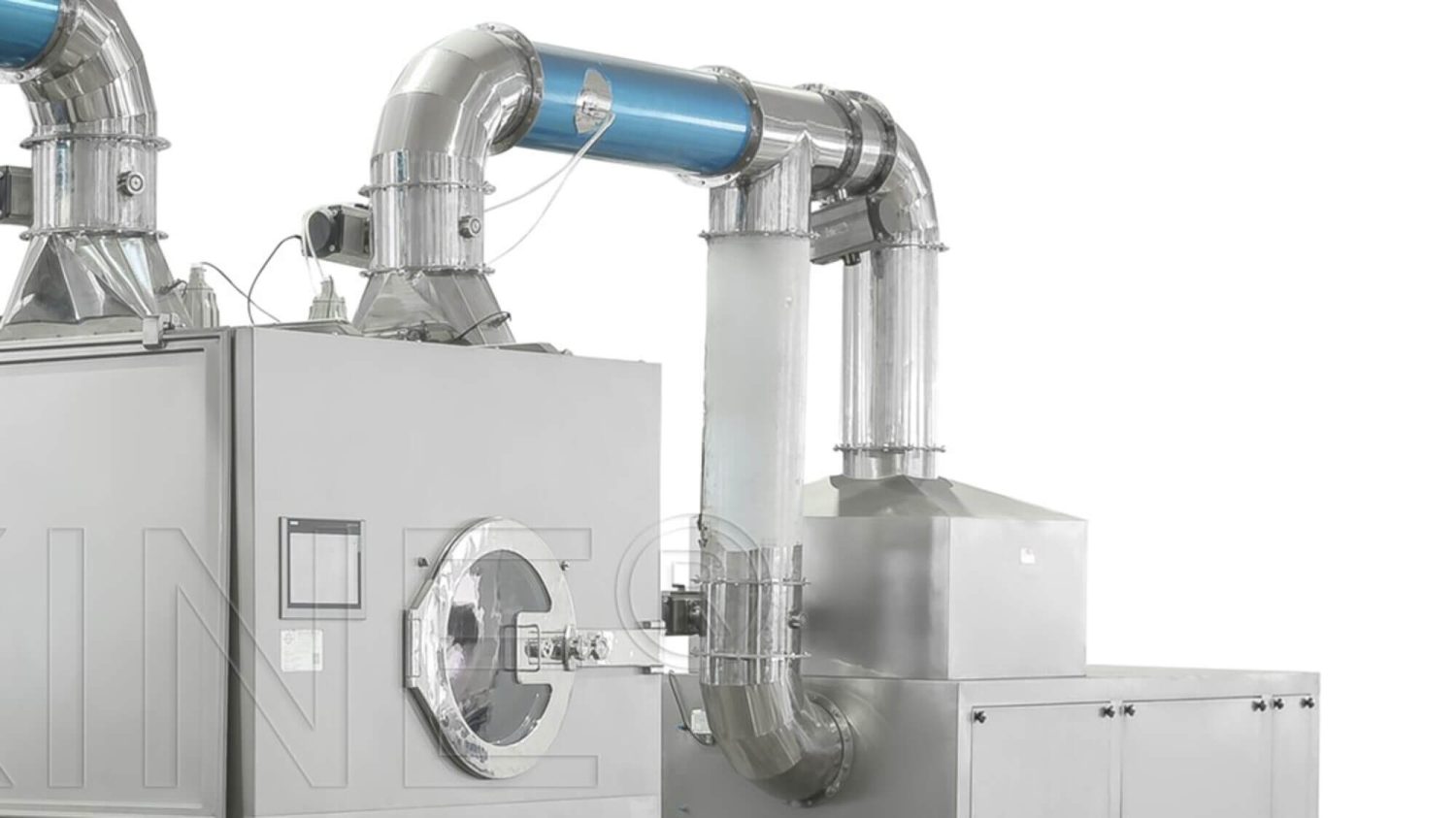

2. Perforated Coating Pan

Most pharmaceutical companies today use perforated coating pans for film coating. This pan coater also features a stainless steel drum. The key difference from the standard coating pan is that the drum has lots of small holes and is enclosed in a machine cabinet. You can see how it looks in the image below.

Perforated coating pans are usually fully automated systems. The spray rate, hot air flow, drum speed, and other parameters are all controlled by a PLC. Because of this, they’re often called auto coaters. They can handle large batches and deliver a uniform coating in just a few hours or less.

These pans also come in two styles: fully perforated and partially perforated. Fully perforated pans give the best drying. Partially perforated models handle air in a slightly different way, but they still dry faster and more evenly than traditional solid pans.

Pros and Cons of Perforated Coating Pans

- Pros

- Faster drying and shorter coating time

- Better control of airflow, bed temperature, and other parameters

- More consistent coating quality

- Effectively handle a wide range of film coatings

- Safer to operate than conventional open pans

- Cons

- More expensive than a standard coating pan

- More complex design and installation

- Challenging for cleaning and maintenance

What about other types? You might also hear about fluidized bed coaters. Strictly speaking, fluid bed systems aren’t “pans,” so when we say coating pans, we mean the rotating drum type. If you’re curious about fluid bed coating, stay tuned. We’ll cover pan coaters vs. fluid bed coaters in a later section.

Essential Coating Pan Machine Parts and What They Do

Whether it’s a conventional coating pan or a modern auto coater, all pan coater machines share a few key components.

1. Pan or Drum

The pan is the heart of the coater. It’s a solid or perforated drum, usually made from SS304 or 316L stainless steel. Standard coating pans are slightly tilted. Perforated pans are often mounted horizontally inside an enclosed housing.

Inside the pan, you usually have mixing baffles. These are ridges or bars that lift and cascade the tablets as the pan spins. The tablets thereby tumble inside to get an even mixing and spray pattern.

The rotation speed is adjustable. But it can’t be too slow, or the tablets don’t mix well. It also can’t be fast because the tablets may stick to the walls or not get properly coated.

2. Spray System

This includes the solution tank, pump, and spray nozzles.

The pump pushes the coating solution from a tank through hoses to these nozzles.

In an automated coater, one or several spray nozzles are mounted inside the pan on a spray bar. They atomize the coating liquid into fine droplets and spray it onto the tumbling tablets.

The nozzles should be well arranged to cover the bed evenly. And the droplet size should be adjustable. Both affect how uniform the final coating will be.

3. Air Handling System

Once your tablets are coated, they need to dry. That’s where the hot air comes in. A pan coater has an inlet air unit that blows heated air into the pan.

This system typically has a blower fan, a heater, and often filters and a dehumidifier. The air is usually HEPA-filtered to keep everything clean and pharma-grade. It needs to be heated to the target temperature. For example, 60-75°C for drying aqueous coatings.

The way this air enters depends on the pan design:

- In perforated pans, it’s fed through a plenum and passes through the drum’s perforations.

- In standard pans, it might be via a pipe or simply blowing over the open rim of the pan.

The airflow rate and temperature are very important. They must be high enough to dry the tablets but not so hot that you overheat or blow the tablets out of the pan!

4. Exhaust System

The evaporated solvent has to leave the pan. A fan draws air out of the coater through an exhaust duct. In perforated pans, the exhaust pulls air through the tablet bed; in standard pans, it might simply capture the hot moist air rising off the tablets.

This system often includes a filter to catch overspray droplets or dust so they don’t vent straight out. It also maintains a slight negative pressure inside the pan. This is important to ensure that the coating spray stays contained.

In simple terms, the exhaust constantly removes moist air so fresh dry air can keep coming in to dry more of the coating.

5. Control Panel or HMI with PLC

Standard coating pans usually come with a control panel. The panel features multiple knobs or dials to adjust parameters like pan speed, air temperature, spray rate, etc.

Modern pan coaters are equipped with a PLC and a touchscreen so you can control all the above components. Just like with standard pans, you can set all coating process parameters on it.

For example, the Anxine ATC Pro tablet coater uses a smart PLC control system with an HMI, letting you fine-tune and track the entire coating process in real time.

How Does a Coating Pan Work?

In plain language, a coating pan works by tumbling tablets, misting them with coating solution, and then using heated air to dry each freshly applied layer.

Now, let’s take a look at the typical tablet coating process step by step.

1. Loading the tablets

First, you put the tablets into the pan. Depending on the machine setup, this can be a manual pour or automatically loaded into the pan. So, how many tablets should you load per batch?

A simple way to check if your batch size is suitable for the coating pan is to use this formula:

| 25 ≤ Batch Weight ÷ (Bulk Density of Tablet Cores × Coating Pan Total Working Volume) × 100 ≤ 95 |

✍ Here, 25 and 95 represent the lower and upper recommended batch percentages of the pan’s total working volume.

2. Preheating the tablet bed

The pan then rotates slowly, and warm air is introduced. This “preheat” removes moisture and warms the tablet bed. So the tablets don’t get over-wet during spraying. For example, if tablets are very cold or damp, spraying too soon could make them sticky.

3. Spraying and tumbling

After 10-20 minutes of preheating, the pan speeds up. As the tablets begin to rise and fall in a cascading motion, the spray guns are turned on. They mist the coating solution over the moving bed. The tablets keep tumbling to expose new surfaces to the spray until each one is evenly coated.

4. Drying

At the same time as spraying, hot air is flowing into the pan and through the tablet bed. It quickly evaporates the solvent from the coating.

Depending on the pan design, air passes through the perforations to dry tablets and is pulled out by the exhaust. Or it might be blowing across and exiting the front opening.

5. Layer build-up

Tablet coating needs you to build multiple layers on the core. Spraying and drying continue until the tablets reach a target weight gain. For example, a film coat might be 2-5% of the tablet weight.

Some modern coaters have load cells to check how much solution has been applied. Operators may also take samples during the run to see if the color looks right and the weight is on track.

6. Cooling and discharge

Once the desired coating is achieved, the spray is stopped. The pan may continue to spin with just air to finish drying. If the tablets need to be packed right away, cool air can be used at the very end to lower their temperature.

After that, the pan slows down and the coated tablets are discharged, often via a discharge port. Or you can use a specialized scoop to guide the tablets out as the pan rotates.

👉Pan coating is a batch process. The cycle time can last from 30 minutes to several hours. For instance, a straightforward film coating for pharma tablets might take 1-2 hours. Commercial sugar coating can take much longer, perhaps 4-8 hours or even days.

Applications of Coating Pan Machines

Medications and Supplements

Medicines like tablets and pellets are the most common products processed in coating pans. Those glossy prescription and OTC pills on pharmacy shelves? Almost all of them were finished in a pan coater. In big pharma companies, you’ll find large perforated pans film coating hundreds of kilograms of tablets. You can click on this article to learn more about the pharmaceutical coating.

Nutraceutical and dietary supplement companies also heavily use coating pans to give vitamins, minerals, and herbal tablets a pharma-grade finish.

Confectionery

Candy panning also has a very long history. Even today, those shiny sugar and chocolate shells on candies, chewy sweets, nuts, and seeds are made in coating pans. In candy making, the pans are often called panning machines. They work on the same principle: tumbling the cores and adding sugar or chocolate layers. These setups are usually based on standard pans.

Agricultural Products

In agriculture, seeds are often coated with nutrients or protective chemicals. Besides fluid bed systems, smaller coating pans can sometimes be used for pelleted seeds or when applying preservation and pest-resistant coatings.

Cleaning and Maintenance Tips for Coating Pans

Just like any machine on your line, a pan coater needs regular care to perform well. Here are some useful maintenance and cleaning tips:

✅ Regular Cleaning: After each batch, or at least at the end of the day, clean the pan and all contact parts. If your coater has CIP, use it.

- For water-soluble coatings, warm water is usually enough.

- For sugar coatings, hot water is very effective.

- If you used enteric or insoluble polymers, you might need a cleaning solution.

✅ Periodic Deep Cleaning: Schedule a deeper cleaning weekly or monthly. That can include removing the spray bars, cleaning or replacing air filters, and checking the exhaust duct for any buildup. Also, clean the pan seals and door carefully.

✅ Wear-Part Checks: Regularly inspect the pan’s drive system and listen for unusual noises during operation. Check the spray pump and lines for any leaks or wear. Replace any chipped nozzles. Swap filters as recommended.

✅ Lubrication: Use the proper lubricant at all lubrication points. Change the oil in the reducer housing and bearing assemblies at least twice a year.

✅ Documentation: Note down every cleaning and maintenance task you perform. If something goes wrong later, those records make troubleshooting much easier.

Pan Coater vs. Fluid Bed Coater

Before we wrap up, remember we said we’d compare coating pans with fluidized bed coaters? Let’s check out now!

| Pan Coater | Fluid Bed Coater | |

| Coating performance | Gentler tumbling, less risk of chipping or breakage; excellent uniformity | More aggressive movement, higher risk for large or fragile tablets; very uniform for small particles |

| Coating speed | Can be as fast or faster for big tablet batches | Fast layering and functional coatings with top or bottom spray options |

| Process complexity | Simpler design and operation | More complex system with tighter process control |

| Equipment cost | Lower cost for similar capacity | Higher initial cost |

| Utilities & air use | Moderate air and utility demand | High air consumption, stricter air velocity control |

| Operator training | Easier to train and learn | Steeper learning curve |

| Coating types | Film coating and sugar coating, thick layers | Thin coatings, powder layering, pellet coating |

| Typical applications | Standard tablet and capsule film coating | Pellets, beads, seed coating, active layering on small cores |

| Multi-function use | Mainly coating | Can also be used for drying and granulation |

| Drying efficiency | Good, but less intense | Very high, each particle surrounded by air |

| Maintenance & cleaning | Simpler to clean: drum and ducts | More filters and tall chambers, slower to clean |

| Changeover time | Usually quicker changeover | Changeover can take longer |

| Who usually chooses it? | Typical tablet manufacturers | Companies with special particle processes |

FAQs About Coating Pan Machines

Q1: Can one coating pan handle both film and sugar coating?

A: Yes, you can use the same coating pan to film or sugar coat products. Just make sure the coater has flexible air and spray systems. And clean the pan thoroughly between runs. But film coating typically works best with perforated pans.

Q2: Is a perforated coating pan always better than a traditional pan?

A: Not always. Perforated drums are more efficient for film coating and are standard in modern pharma plants. Traditional solid pans can still be a good fit for simple sugar coatings.

Q3: Can I use a pan coater to coat capsules?

A: Yes. Especially perforated pan systems. But the process parameters should be carefully controlled because capsules are more delicate.