Have you ever thought about how the pills you take every day have their perfect shape? If you work in the medicine business, you probably know about the tablet press machine. It’s the main gadget that turns loose powders into solid, handy pills.

But what makes that machine so special? It’s the tablet press tooling. Think of it as the special tools that shape the powder into those neat little pills. Do you have any questions about it? What does it do? What kinds are there? Can you get custom shapes? Don’t worry! This guide will explain everything.

What Is Tablet Press Tooling?

The tablet press tooling is the most vital component of the tablet press machine. This special setup shapes, squeezes, and pushes out each tablet. Its job is to ensure that every pill is the same size, shape, and strength.

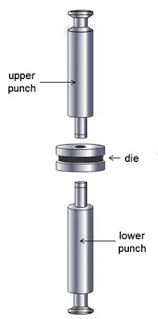

This essential component has two main parts:

Punches: These are like plungers and are usually found at the top and bottom. They are cylinder-shaped and press the powder into a tablet. On simpler machines, only the top punch moves down. However, on faster, spinning machines, both the top and bottom punches work together. The top punch pushes air out while the bottom punch holds the powder and then lifts to release the finished tablet.

Die cavity: This is basically the tablet’s mold. It’s a hollow space that determines the final shape and width of the pill. Powder fills the mold before it’s pressed. The depth of the mold also determines how thick the tablets will be.

Why Tablet Press Tooling Matter?

How do tablets get so precise? A lot of it comes down to tablet press tooling! This part is super important. Here’s why using good tooling makes a huge difference:

Better Tablet Quality

Tooling directly controls how your pills look and feel – their shape, design, strength, and any marks. Good tooling means every tablet has the right weight and dose, with no weird differences.

Easier to Follow Rules

Groups like the FDA have strict rules for pill doses and what’s printed on them. Tablet press tooling makes it easy to follow these rules. You can make pills with exact doses and clearly print important info like names or logos. This helps track products and keeps patients safe.

Faster Production

The right tooling helps your tablet press run much quicker. Since it’s made from strong materials, it lasts longer, so you don’t replace parts often. This makes production smoother, with fewer stops, boosting how much you can make!

Less Wasted Material

Wasting materials costs money. But good tooling greatly cuts down on bad pills. This saves raw materials and means fewer batches get thrown out or recalled.

Make Custom Pills

Want unique tablets? Tooling makes it possible! It can be custom-made for almost any shape or size. It even handles tough powder mixes that don’t flow well or are hard to press, helping you create truly special tablets.

What are Different Types of Tablet Tooling?

Ever wondered why tablets come in so many different shapes and sizes? From tiny rounds to big ovals, it’s pretty amazing! The secret? Different kinds of tablet press tooling. Each type is built for specific tablet shapes and sizes. Let’s dive in and see what they are:

D Tooling

This type is your go-to for larger tablets. Because it uses bigger parts (like a 1-inch punch and 1.5-inch die), it can apply a lot more pressing force. That makes it perfect for heavy-duty jobs like creating big chewable tablets, very large pills, or ones packed with many active ingredients.

B Tooling

If you want to make smaller tablets, B-type tooling is the best option. Its punch diameter is smaller (about 0.75 inches or 19 mm), and its die diameter (0.945 inches) is also less than D tooling. Because it is small, more B tooling units can fit onto a tablet press machine. This makes it popular for standard-sized tablets and supplement pills.

DB Tooling

It’s a special kind of D tooling, but for medium to large, very dense tablets. Its die (mold) is a bit smaller than regular D tooling, so more units can fit on the press. The punch size is still large, like D tooling.

BB Tooling

This is the smallest of the group, a modified B tooling. It has even smaller parts (around 0.75-inch punch and die) which means you can fit the most of these on a machine. Super popular for tiny tablets like mints or lozenges (up to about 13mm).

What are the Different Shapes of Tablet Press Tooling?

Ever wondered how tablets get all their different shapes – from round to oval, or even with a hole in the middle? It all comes down to the clever designs of tablet press tooling! Each type is made for a specific purpose, so we can create a huge variety of tablet shapes and sizes. Let’s look at the main ones:

Standard Round Tooling

This is the most common type used to make classic, round tablets. It’s the go-to choice for pharmacies and pet medicines, producing simple, familiar shapes that can be flat or slightly curved.his is the classic, popular, and versatile machine that makes those familiar, perfectly circular tablets.

Oval Shaped Tooling

As the name suggests, this tooling creates oval-shaped tablets. It’s a popular choice for medicines and herbal supplements. It’s used to make smooth, elongated pills that can be flat or a bit deeper.

Capsule Shaped Tooling

Want a tablet that looks just like a capsule? This tooling does it! It makes long, oblong pills with rounded ends. Used a lot in medicine, these capsule-like tablets often look nicer to consumers.

Geometric Shaped Tooling

If you need tablets with sharp, distinct shapes like triangles, squares, or rectangles, this is the tooling for you. It’s not just for medicine — you’ll also find it shaping candies, chemicals, and even metal parts.

Irregular Shaped Tooling

You can make unique, custom tablets in all sorts of shapes, like animals, fruits, stars, or diamonds. You’ll usually see these creative designs in the candy world.

Core Rod Shaped Tooling

Need a tablet with a hole in the middle? This special tooling makes it happen! It’s common in pharmaceuticals, candies, and ceramics, creating those distinctive pills with a central opening.

Multi-tip Tablet Press Tooling

Instead of making one tablet at a time, this tooling has punches with multiple pressing tips. This means you can make several tablets at once, which increases how many you can produce.

Sealed Groove Tablet Press Tooling

This smart tool helps you keep things clean and exact. Its special seal stops powder from coming out during the pressing process. The result is a cleaner process and perfectly consistent tablets every time.

What Are Possible Problems Related to Tablet Press Tooling?

Tablet press tooling may cause issues that compromise your finished pills, such as breaking or powder sticking to tablets. While these issues often originate within the tooling itself, keeping it in good shape should help address or minimize them. Let’s examine some frequent issues and their solutions:

1. Sticking and Picking

Sticking is when tablet powder clings to the punch and die walls. Picking is similar, but it’s when powder pulls off the tablet and gets stuck in engraved areas on the tooling. Both often occur if your powder mix is too wet or just naturally sticky.

How to fix it?

To prevent this, use high-grade stainless steel tooling (especially with more chromium). You can also add special anti-stick coatings like chromium or DLC to the punch faces. Sometimes, simply adjusting your tablet’s recipe by adding more lubricants helps the powder flow smoother.

2. Tablet Breakage and Chipping

Are your tablets breaking or missing pieces? This often points to problems with your tooling. Old or damaged punches and dies can press unevenly, making pills weak. Also, if tooling isn’t lined up right, or isn’t lubricated well, it creates too much friction. This extra stress can cause tablets to crack or chip.

How to fix it?

Check your tooling regularly for wear and quickly replace any damaged parts. Always make sure your tooling is perfectly aligned and calibrated. And remember to use food-grade oils on punches and dies to reduce friction.

3. Tablet Splitting and Layering

Does your tablet split horizontally (capping), or peel apart into layers (lamination)? Capping often happens because air gets trapped in the powder due to the punch’s design. Lamination usually comes from pressing too hard, poor powder flow, or weak bonds between powder particles.

How to fix it?

Often, changing the design of your punches and dies helps. Good designs let trapped air escape better and make layers stick together stronger. You can also adjust your tablet’s formula for better powder flow, or fine-tune machine settings like pressing force or how long tablets remain under pressure.

4. Degradation of Tooling Surfaces

Are you finding small dents or rust spots on your tooling? This can be from rough ingredients, too much pressure, not enough lubrication, strong cleaning chemicals, or even high humidity.

How to fix it?

You can adjust your tablet formula by using fewer abrasive ingredients or grinding them more finely. You can also reduce stress on the tooling by adjusting machine settings. Properly lubricate and clean your tooling. Most importantly, store your tablet press tooling in a dry, controlled environment to prevent rust and pitting.

5. Cross-Contamination

Contamination can occur if powder leaks from tooling parts, builds up on punch tips, or accumulates inside the die. This can result in impure tablets and even cross-contamination between different batches.

How to fix it?

Consider changing your tooling design to include options like sealed groove tooling to keep the powder inside. Also, always follow a strict cleaning schedule for all equipment between every batch.

The Bottom Line

The tablet press tooling is truly the heart of any tablet press machine. It’s the key part that makes loose powders into perfect tablets by applying steady pressure. Choosing the right tooling is very important because it makes sure that your tablets are exactly the right hardness, thickness, size, and shape. Want to see how a high-quality tablet press machine can improve your production? Contact Anxine today!