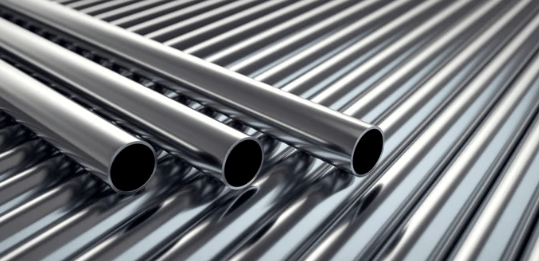

Stainless steel is widely used in various products today. It features a shiny surface, a solid feel, and good strength. It could also stay clean after years of use. But many people find it hard to recognize whether something is truly stainless steel or just looks like it. The surface might seem similar to aluminum or chrome, but their properties are quite different. So, a good understanding of how to differentiate them is important.

What is Stainless Steel Made of?

Stainless steel is a metal made from an alloy of iron, chromium, and nickel or molybdenum. It also has a thin protective layer on the surface to resist rust and stains. Stainless steel is widely applied in machine parts, medical equipment, and construction. Because it looks clean, lasts long, and does not easily react with water or air.

Why Should You Know If It’s Real Stainless Steel?

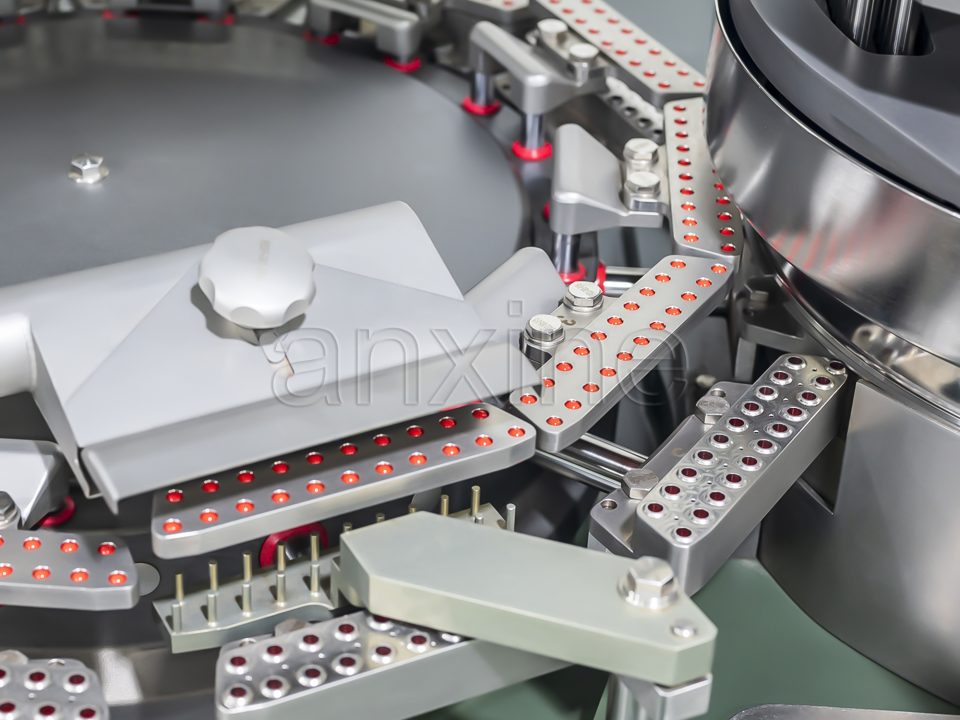

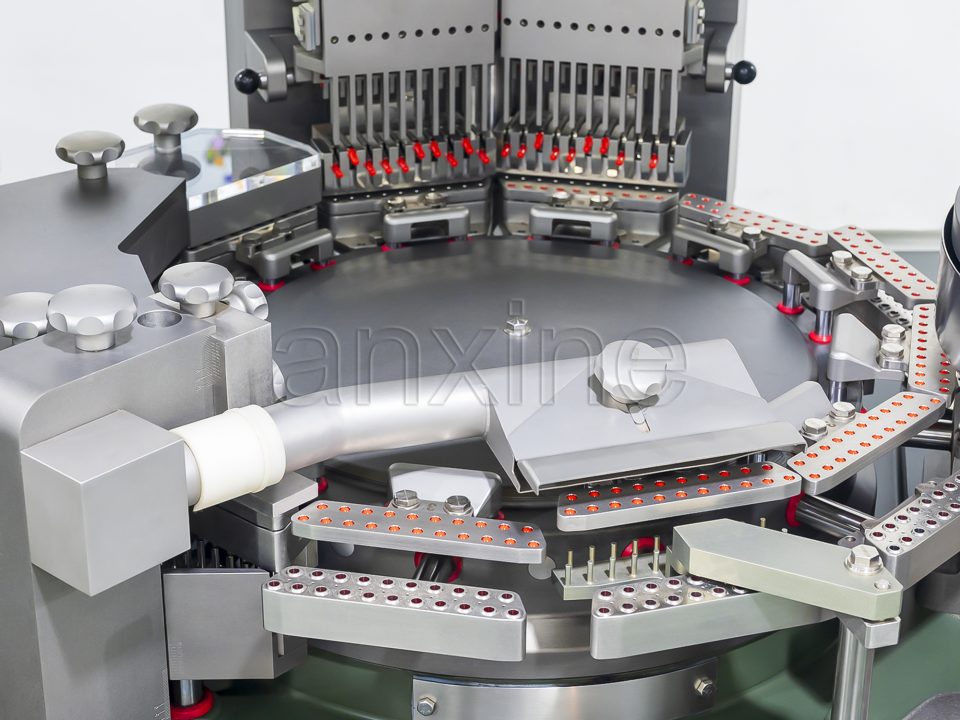

It is useful in many situations, especially when you want to buy equipment for production. For example, in pharmaceutical manufacturing, the capsule filling machine is made of stainless steel. It provides many advantages. The smooth surface prevents powder buildup. The corrosion resistance keeps the equipment safe from moisture and cleaning chemicals. True stainless steel also helps maintain hygiene and extends the machine’s service life. Because of these benefits, stainless steel is one of the most reliable materials in industrial production. But if you buy one with fake materials, it may cause lots of problems.

How to Identify Stainless Steel?

There are many ways to help you find the real stainless steel. Here are some common methods for your reference.

Magnet Test

This is one of the easiest ways to check if a metal object is stainless steel. Most types of steel are made from iron, so they are usually magnetic. This means a magnet will stick to them. In contrast, metals like aluminum or copper are not magnetic, so the magnet will not react at all.

However, not all stainless steel behaves the same way. Some types attract magnets, while others do not. This difference depends on what elements are added during manufacturing. For example, when nickel is added to stainless steel, it changes the internal structure of the metal and removes its magnetic properties. That is why many high-quality stainless steels, such as those used in capsule fillers, are not magnetic. High-manganese steel is also non-magnetic. Moreover, some complex chrome-nickel-nitrogen steels may be magnetic in one direction but not in another.

So, the magnet test is a quick way to tell whether a metal could be stainless steel and what general type it might be. But it cannot tell the exact grade or composition. It’s best used as a simple first step before doing more accurate tests.

Appearance

Stainless steel has a very recognizable look. It usually appears silvery-gray, with a smooth surface and a mirror-like shine. When in the light, the surface reflects gently. This balance makes stainless steel look clean and smooth.

Many people confuse stainless steel with other shiny metals, such as aluminum or chrome. Here are simple ways to differentiate them.

- Aluminum has a more matte or dull surface. When you touch it, it feels softer and warmer than stainless steel. Aluminum is also much lighter in weight.

- Chrome has a very bright and mirror-like finish. It looks smooth and polished, but chrome is always used as a plating on another metal. Over time, the chrome layer can peel or bubble, while stainless steel stays even and rust-free.

Rust Check

This is another simple way to test stainless steel. Ordinary steel rusts quickly when it touches water or stays in a humid place. After just a few days, you may see brown or reddish spots forming on the surface.

Stainless steel behaves differently. It contains chromium for better protection. This layer protects the metal from reacting with air and water. Therefore, stainless steel does not rust easily in the humid environment.

Weight and Density

Stainless steel is dense and heavy. It feels solid and firm. In comparison, aluminum is much lighter and softer. Weight comparison is especially useful in industries like pharmaceuticals or food production. A heavier and sturdier part ensures the machine is strong enough to handle daily operation, cleaning, and pressure.

Spark Test

A spark test is a traditional way to identify metals. It is often used in workshops or factories. In the test, a bench grinder is needed to contact the metal. Then, the sparks will come out. Different metals create different spark patterns and colors.

When carbon steel touches the grinder, it produces bright yellow or orange sparks. The sparks are usually long, straight, and energetic. The higher the carbon content, the more intense and branching the sparks become.

Stainless steel, however, produces shorter and fewer sparks. The sparks are usually red or dark orange, and they do not spread as far. This is because stainless steel contains elements like chromium and nickel. As a result, the sparks appear softer and darker compared to carbon steel.

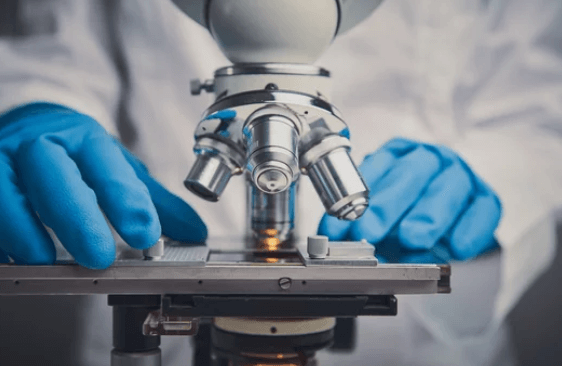

Chemical Test

A chemical or acid test is a more accurate way to confirm whether a metal is stainless steel. This method is often used in large factories or quality control labs. It applies a small amount of nitric acid to the metal surface. Then you can see how it reacts.

When nitric acid touches stainless steel, there is usually no strong reaction. It means the surface will stay bright and clean. Because there is a protective layer that prevents the acid from damaging. In contrast, ordinary steel or iron reacts quickly with nitric acid. It would produce brown stains, bubbles, or rust marks. These reactions show that the metal is not stainless steel.

Label Check

A label check is the easiest and safest way to identify stainless steel. It is especially useful for finished products or machine parts. Many metal manufacturers mark their products with material information, which can be found on labels, tags, or markings. These marks often include a grade number or code that tells you what type of stainless steel it is.

Common stainless steel grades include the following types.

- 304 stainless steel is the most popular one in the market. It is used in kitchen tools, pharma, and food equipment. It resists rust, and the material is easy to clean.

- 316 stainless steel contains more nickel and molybdenum. It has stronger corrosion resistance, especially against chemicals and saltwater.

- 430 stainless steel is magnetic and often used for decorative or less demanding parts.

However, not every product carries a clear label. In that case, other testing methods are needed to confirm the metal.

The end

Stainless steel has many advantages for manufacturing. Its resistance to rust and corrosion makes it essential in different industries. As technology continues to develop, stainless steel will remain an important part of daily products.