Have you ever seen this happen? You start feeding powder into the tablet press, and suddenly the hopper clogs. Or filled capsules get flagged by the metal detector for foreign objects before blister packaging. In many cases, the real culprit is poor sifting.

If you want fewer headaches when making tablets or capsules, getting sifting right will help a lot. Read on, and this guide will show you how.

What is the Sifting Process in Pharma?

First, let’s go over the basics. In simple terms, sifting is the process of passing your material through a mesh to filter out unwanted things. These unwanted objects include oversized particles, soft lumps, and foreign matter. Sifting is just like a checkpoint that lets only acceptable particles pass.

But if you’re new to pharma manufacturing, you might mix up sifting with other steps. To clear up confusion, let’s see what sifting is NOT.

- NOT milling. Milling aims to reduce particle size. The sifting process only screens and separates them.

- NOT blending. Blending mixes ingredients to create a uniform mixture. Sifting is not for combining things.

- NOT metal detection. Sifting may catch some foreign particles, but it can’t “find” metal.

Common terms you’ll see in the sifting process in pharma:

- Sifting vs. Screening vs. Sieving

- People often use these interchangeably. “Sifting” and “Sieving” are usually for fine powders. “Screening” is more common for coarser materials.

- Security Sieving

- An inline check to stop contamination or oversize.

- Grading

- Separating material into more than one size fraction.

- Particle Size Distribution (PSD)

- The spread of particle sizes in a sample. It can affect how the powder flows, mixes, and compresses.

- De-lumping or De-agglomeration

- Breaking soft lumps and letting them pass.

Why Sifting in the Pharmaceutical Industry Matters

It protects product quality. Pharma materials must be pure before tablet compression or capsule filling. By removing foreign particles and contaminants, sifting reduces safety risks that could harm patients.

It ensures uniform drug content. PSD affects how fast the active ingredient dissolves and is absorbed. The sifting process sieves out the odd sizes to achieve consistent particle sizes. That ensures each drug dose has the same amount of APIs.

It prevents downstream issues. One lump can jam a feed hopper or even damage the tooling. Sifting gives you properly sized, free-flowing powder that can go smoothly into the next machines.

It cuts down on rework. Sifting catches problems early. It can remove contaminants, off-size particles, and lumps before compression, filling, or packing. That way, you’re less likely to scrap a batch or pay to redo work later.

It fits into regulatory compliance. Sifting steps and their mesh sizes are often documented in the batch record and process validation file. It’s considered a Critical Control Point in processes.

How the Sifting Process in Pharma Works Step by Step

Sifting in the pharmaceutical industry usually follows a similar pattern. Once you understand the steps, you can walk up to almost any pharmaceutical sifting equipment setup.

Step 1: Load the material

First, the material to be sifted is loaded into the sifting equipment. How it happens depends on the setup. The powder can be hand-scooped into the sieve, gravity-fed in through a hopper, or transferred in via a vacuum system.

Step 2: Sieving action begins

Once the powder is in, the sifter machine runs to separate particles.

A vibro sifter uses an electric motor to create vibration that shakes material across the screen. In a centrifugal sifter, a paddle rotor spins inside a cylindrical screen to throw particles outward so they pass through the mesh.

The motion encourages smaller particles to find the mesh openings and fall through. At the same time, larger particles are directed to a separate discharge outlet.

If the sifter has multiple decks, the material might pass through a coarse mesh first and then a finer one. This lets you separate two or more size fractions in one go.

Step 3: Separate particles

As the sifter vibrates or spins, particles smaller than the mesh openings pass through and collect below. This is your sifted product. Particles that are too large stay on top of the screen. These may be hard lumps, foreign debris, or other contaminants.

And here’s an important detail: soft clumps are “tested” in this step. That means the movement makes them hit the screen and fall apart. So the pieces left behind are usually the ones that won’t break up and are truly too large.

Step 4: Start the next run or continue sifting

From here, sifting usually runs into two ways: batch or continuous. In a batch mode, you stop once all sifted material is collected. In a continuous mode, the first three steps just keep cycling again and again.

Step 5: Collect the sifted material

The sifted fine particles pass through the mesh openings and fall from the screen into a clean bin. Oversized material is left on the sieve or discharged separately into another collection point.

Step 6: Handle oversize material

So what do we do with that oversize left on the sieve? These oversized materials are usually removed and inspected. Sometimes they’re just big granules that didn’t break. They might be broken down again using a mill and then resifted.

This recycling approach is common in pharma manufacturing. For instance, granules that do not pass through a 20-mesh screen are considered coarse. They need to be milled and then sieved again.

If they’re contaminants or useless chunks, they might be just scrapped.

Step 7: Clean the sifter

Powder can hide in small gaps or around the mesh. So, the sifter needs to be thoroughly cleaned after the process. Most pharmaceutical sifters are easy to disassemble so you can clean or even sterilize contact parts to avoid cross-contamination. For example, modern vibro sifters often have quick-release clamps that let you remove the sieve decks fast for cleaning.

Types of Pharmaceutical Sifters

You may have noticed a few sifting machine names mentioned above. There are indeed several options for the sifting process in pharma. Here are the major types to know.

1. Vibro Sifters

These are perhaps the most common sifters in pharma. A vibro sifter uses an electric motor with eccentric weights to generate fast vibration. The movement forces powders to spread across the sieve, and the on-spec ones move through the mesh.

Most pharmaceutical vibro sifters are circular screen separators. They usually have one or more stainless-steel sieve decks. They use covers, flexible seals, and clamps to create a dust-tight system.

✅ Pros:

- Versatile across many powders and granules

- Easy to use and simple to maintain

- Effective for general screening, security sieving, and grading in one machine

- Allow quick screen changes

❗ Watch-outs:

- Must be installed on a stable, level surface

- Can be a bit noisy

- Might struggle to break down very lumpy or wet materials

- Screen can blind with sticky or static fine powders

✨ Best for:

- General-purpose sieving of dry powders and granules

- Safety sieving of ingredients

- De-lumping soft agglomerates

2. Centrifugal Sifters

A centrifugal sifter is sometimes called a rotary sifter. It’s a fully enclosed system. Material feeds in from one end and exits at the far end.

This sifter rotates a paddle at high speed inside a cylindrical screen. The spinning action generates centrifugal force that pushes material against the screen. At this point, on-spec finer particles slip through the mesh openings and exit from the outlet. And oversize or unwanted material is discharged from the reject end.

✅ Pros:

- Can handle a larger volume of material much faster than a vibro sifter of similar size

- Very good for enclosed, dust-free operation

- Better accuracy in separation and lower maintenance

- Offer quieter and less violent vibration

- Very gentle on friable granules

❗ Watch-outs:

- Can not handle multi-deck separations

- Not ideal for sticky or moist materials

- A little involved to clean the inside of a long sifting drum

- Not to overload

✨ Best for:

- High-volume powder sifting

- Inline security sieving for bulk powders

- Powders that need gentle handling or form lumps easily

3. Ultrasonic Sifters

An ultrasonic sifter looks a lot like a vibro sifter. It uses a similar multi-deck setup to separate particles. So what’s different? An ultrasonic sifter attaches an ultrasonic frequency generator to the screen frame. That generator sends high-frequency, low-amplitude vibration into the mesh. Usually, it operates at 20-40 kHz, which is largely inaudible to the human ear.

Ultrasonic sifting makes the mesh shake so quickly that particles don’t get a chance to lodge in the holes. That effectively reduces mesh blinding and improves fine powder screening.

✅ Pros:

- Greatly reduce screen clogging

- Allows very fine mesh sizes

- Helps fine meshes run longer without blinding

- Boost the throughput of fine sieving

❗ Watch-outs:

- Ultrasonic transducers need to be tuned regularly

- Mesh for ultrasonic use can be pricier

- Specifically used when necessary for difficult-to-screen materials

- Still need a normal vibration or some incline to make powder flow

✨ Best for:

- Fine and ultrafine sifting tasks in pharma

- Sticky, static-prone materials

- Products that need very tight particle size control

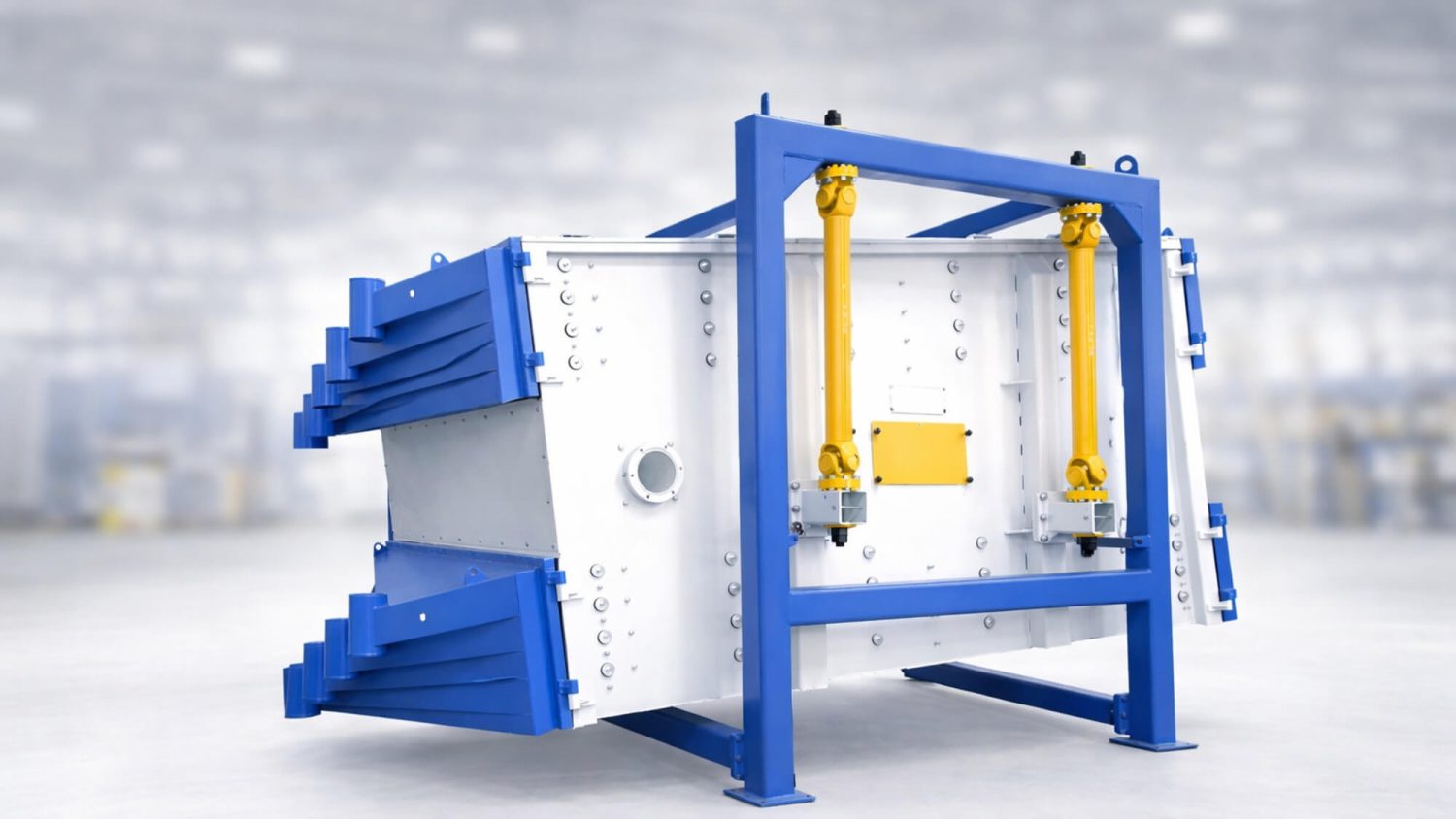

4. Gyratory Sifters

A gyratory sifter also features a multi-deck design. But it works a bit differently. Instead of strong vibration, the gyratory sifter moves the sieves in a gentle, low-angle, circular motion. The eccentric drive helps spread material evenly across the screen surface.

Gyratory sifters are considered large industrial machines in this category. They commonly feature big rectangular or square screens to handle high-volume, high-capacity screening operations.

✅ Pros:

- Very gentle on fragile materials

- Have large screening areas and multi-deck grading for high throughput

- Known for accurate separation even for particles that are close in size

- Low noise and less aggressive vibration

- Fast, tool-free screen changes and easy access for cleaning

❗ Watch-outs:

- Larger footprint

- Less commonly seen than vibro or centrifugal sifters in pharma

- Higher cost and complexity

✨ Best for:

- High-precision sizing

- Pellet sifting to remove fines and overs in one pass

- High-capacity and low-breakage grading

Common Sifting Problems and Practical Troubleshooting

Below is a handy table of common issues in the sifting process in pharma. If you’ve run into any of them, use it to spot likely causes and apply practical fixes.

| Problem | Likely Causes | Practical Fixes |

| Screen is blinded or clogged. | – Powder is sticky or static. – Mesh size is too small. | – Reduce feed rate – Pre-break lumps – Consider ultrasonic assist – Reduce moisture – Replace the mesh |

| Too much oversize is left on the sieve. | – Feed rate is too high. – Sieve is overloaded. – Screen mesh is too fine. – Speed is too low. | – Slow down the feed. – Adjust mesh size. – Add a pre-sieve. – Increase vibration or rotation speed. |

| Oversized material slips into the on-spec particles. | – Material piles up due to overloading. – Mesh is damaged or torn. – Clamps or gaskets are loose or worn. | – Reduce feed rate. – Add another sieve deck. – Replace damaged or worn screens and seals. |

| Product leaks from seals. | – Gaskets get worn, or clamps get loose. – Screen assembly is not installed correctly. | – Replace gaskets. – Tighten clamps. – Reassemble the sieves. |

| Powders build up in corners. | – Powder is too damp. – Vibration or rotation speed is too low. – Sieves in the sifter are not stacked at a certain angle. | – Reduce moisture in powder. – Increase motion. – Adjust the deck angle. – Improve cleaning frequency |

| Metal or foreign bodies keep showing up. | – Upstream processing gets contaminated. – Upstream equipment gets worn or damaged. | – Inspect the incoming material. – Check and maintain upstream equipment. – Add security sieving. |

| Throughput is lower than expected. | – Mesh openings are too small.- Feeding is too fast. – Screens are clogged. – Powder is moist. | – Replace with a slightly coarser mesh. – Reduce feed rate. – Clean the screens. – Consider a larger screen area or a different sifter. – Improve pre-drying or de-lumping. |

Key Takeaways

- The sifting process in pharma is to filter out oversize particles, soft lumps, and foreign matter before encapsulation or compression.

- Sifting is not milling, blending, or metal detection.

- The basic workflow is simple: load, apply motion, separate on-spec vs oversize, collect, then repeat or stop.

- Vibro sifters, centrifugal sifters, and ultrasonic sifters are more commonly used in pharma manufacturing.

- When issues show up, start with the basics: feed rate, screen condition, seals, moisture, and buildup on the screen.