Capsule filling equipment plays a key role in the pharma and supplement industries. It could fill capsules precisely and quickly. There are many types of capsule fillers on the market. You’d better know them well and get the most suitable one for your business.

What are Capsule Filling Machines?

This equipment is used to fill empty capsules with powders, granules, or small pellets. It can also work with different capsule sizes, such as size 0, 00, or 1. Each capsule will be filled with the correct and same dosage. This is important for medicines and supplements that require effectiveness. Moreover, a capsule filler machine can process hundreds or even thousands of capsules per hour. This greatly increases production efficiency, especially for large companies.

Six Types of Capsule Filling Machines

Manual Capsule Filling Machines

This equipment is mainly used for small-batch production like in laboratories. It needs human effort to fill and seal capsules. At first, the operator places the capsule bodies and caps separately into a plate with matching holes. Then he adds the powder into the open capsule bodies, and spreads it evenly with a scraper. Finally, he needs to lock the capsules together by compressing the plates. This machine depends on hand operation and fills usually between 100 and 300 per batch at once.

This type suits dry powders such as herbal extracts, vitamins, or experimental formulations. It is often chosen by companies that need flexibility for different formulas or frequent product testing. Although production speed is low, the cost is small. So manual capsule fillers are preferred by many small business owners and researchers.

Semi-automatic Capsule Fillers

This equipment is used when a company needs higher output but still wants some manual effort. It suits small to medium-sized manufacturers. For this machine, capsules are automatically oriented and separated into body and cap positions. The operator fills the powder hopper, adjusts the fill weight, and then starts the filling process. After the filling is finished, the operator should transfer the filling tray to the sealing station. The machine would seal them tightly for safety.

A semi-automatic capsule filling machine allows easy adjustment for different capsule sizes or materials. The semi-automatic system ensures better accuracy and hygiene compared to manual models. But it also costs more.

Fully Automatic Capsule Filling Machines

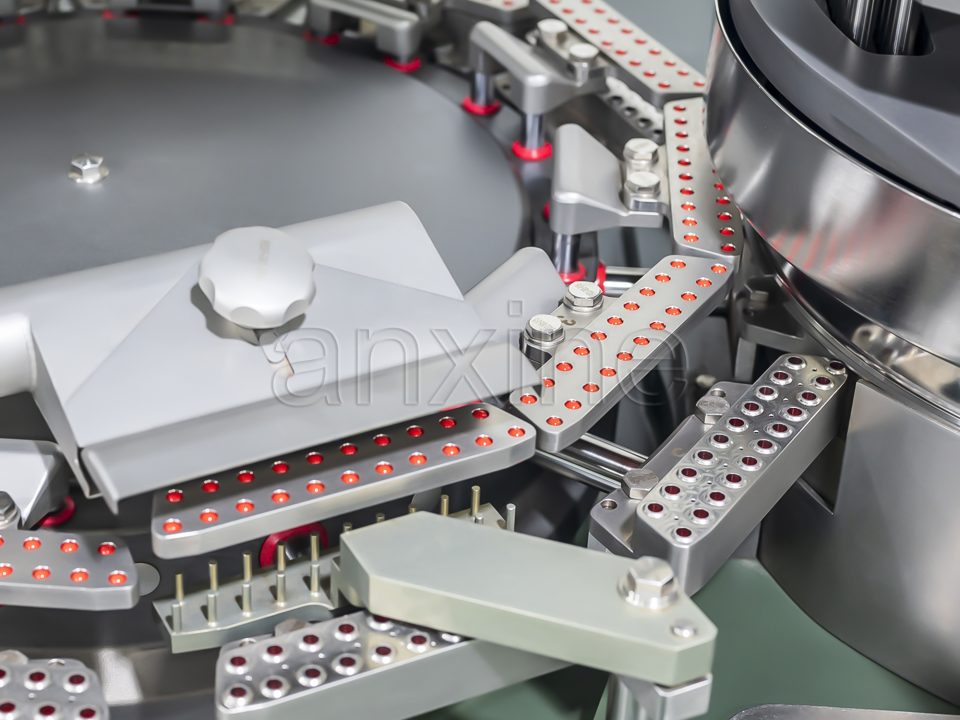

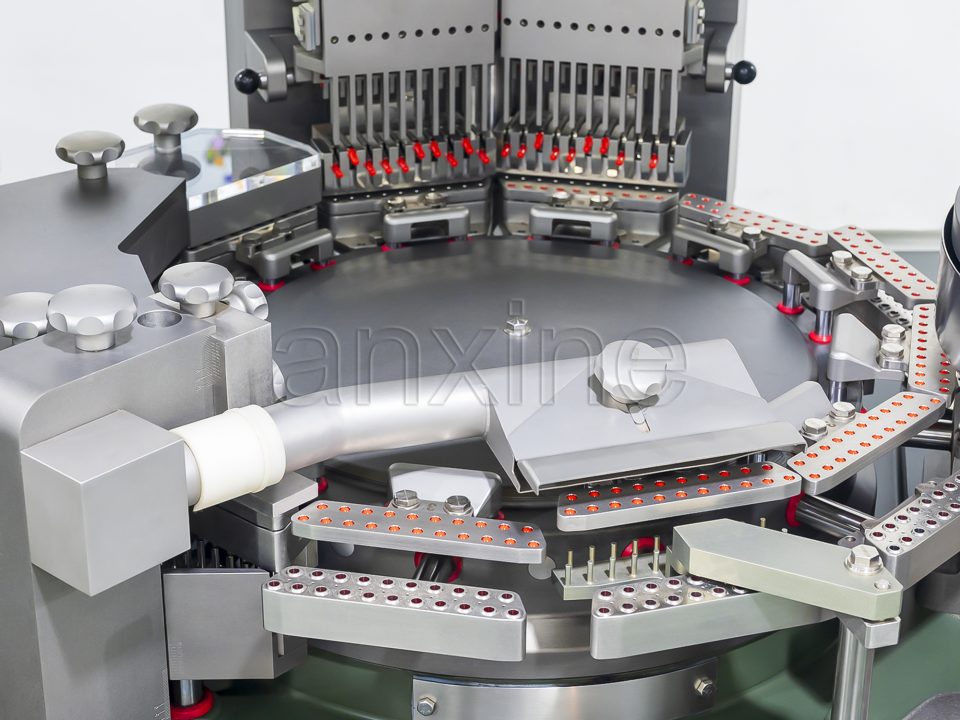

A fully automatic capsule filling machine is designed for large-scale pharmaceutical and nutraceutical production. It can finish the entire filling process automatically, from capsule feeding to sealing. This machine suits high-volume production of medicines, vitamins, and mineral supplements. It works well with dry and free-flowing powders or micro-pellets. Some advanced models can also handle sticky or slightly wet materials with special dosing systems.

Fully automatic capsule fillers feature a fully enclosed structure and sensitive sensors control. They prevent contamination, and ensure good stability and safety. They also feature a high production speed, often tens of thousands of capsules per hour. So, fully automatic models are commonly used in large companies that require high efficiency and precision.

The three types above are divided based on automation levels. There are also other types for different purposes.

Liquid Capsule Filling Equipment

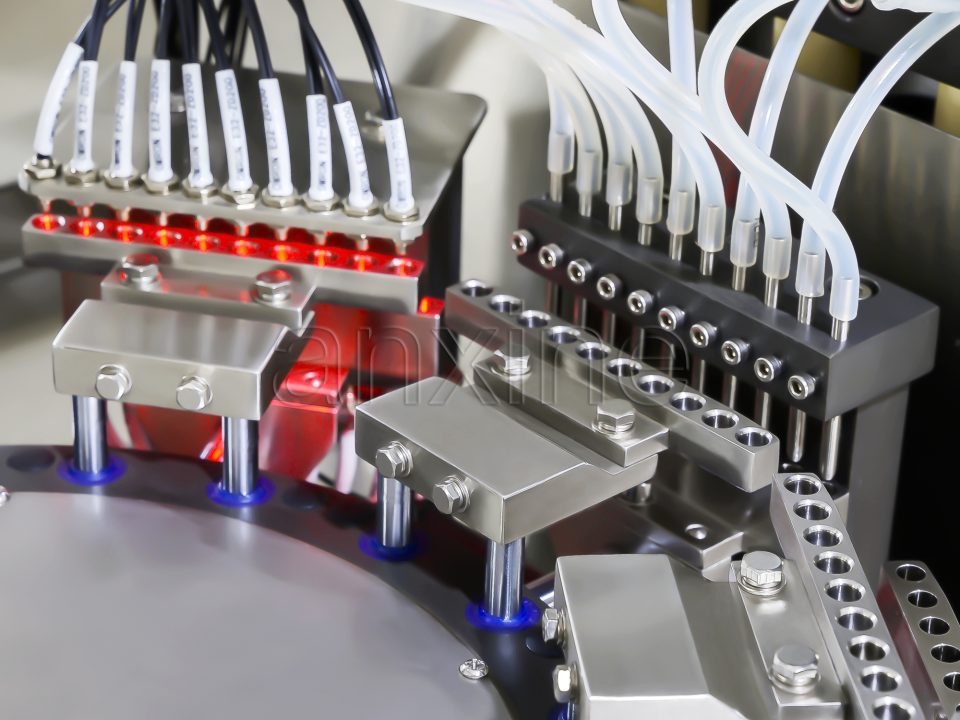

A liquid capsule filler is used for filling capsules with oil-based liquids, suspensions and pastes. These materials are often used in functional health supplements. They combine the high absorption rate of liquids with the traditional appearance of hard capsules. In addition, some high-viscosity liquids, syrup-like extracts can also be filled into hard capsules, such as alcohol-based tinctures. These liquids are suitable for research applications or high-end pharmaceutical formulations. To prevent the capsule shell from softening or leaking, HPMC capsules are often used for better stability.

The filling process is similar to that of hard capsules. Liquid filling machines always use heat or ultrasonic technology to avoid leakage. Some models use thermal or ultrasonic sealing technology for better protection.

Softgel Eencapsulation Machines

A softgel filling machine is used to produce soft gelatin capsules. It suits materials that are hard to compress into tablets. They include oils, emulsions, or active ingredients that need protection from air or moisture. Unlike hard capsules, softgels have a flexible and integrated shell. The shell protects the liquid inside. It also has a smooth texture for easy swallowing. Sofegels are widely used in the pharmaceutical, cosmetic, and dietary supplement industries.

The softgel encapsulation machine could form, fill, and seal the capsule in one continuous process. Two thin gelatin ribbons are first prepared and fed into the machine. These ribbons are shaped into small bags while the liquid material is injected between them. The machine then seals the ribbons together, cuts out the capsule shape, and dries the softgels for ejection.

Special Capsule Fillers

These are the advanced models among so many types. They are often used in materials that will be easily affected by moisture, oxygen, or static electricity. Ingredients such as antibiotics, probiotics, or hygroscopic compounds need this type of machine.

The working system usually includes vacuum filling, inert gas protection, and dust collection features. The machine creates a clean and controlled environment to protect the material’s stability. Some models have temperature and humidity control units for flexible production. This type is suitable for advanced drug production, contract research centers, or supplement factories that handle sensitive or high-value ingredients.

How to Choose a Suitable Capsule Filler?

Material Properties

This is the first factor you should consider. Powders or granules with good flow can be filled easily by a standard capsule filler machine. Oil-based or semi-liquid materials require a liquid or softgel filler. They are more precise in temperature control. If you need to fill moisture-sensitive or active ingredients, you may need a special material filler with vacuum or nitrogen protection to maintain stability.

Production Volume

Then you need to consider how many capsules you want to produce in a day. If you are a start-up, a manual capsule filler is enough for production. It improves efficiency and costs less. If you want to balance efficiency and cost, semi-automatic capsule filling machines are much better. Fully automatic capsule fillers are the most expensive and the most efficient. So they are ideal for large production lines.

After-sales Support

A high quality machine is related to a reliable supplier. He should provide technical service, training, and spare parts when you meet problems. This support helps you get a stable operation and reduce downtime. For long-term production, a local or easily reachable service team is important.

Get your High-quality Capsule Filler with Anxine

As a leading equipment manufacturer in China, Anxine offers a wide range of capsule filling equipment. Whether you run a small or big business, there must be a machine to meet your needs. You just tell us your requirements, and we will select the most suitable one for you. We provide 24/7 support to solve your problems in time. If you need technical training or spare part replacement, just feel free to contact us.