Making capsules for the first time? Or trying to get better filling performance? Knowing how to operate your capsule filling machine is the key. Capsule fillers might seem technical, but once you get the basics, the whole process becomes much easier to manage.

In this post, you’ll learn how to use manual, semi-automatic, and automatic capsule filling machines. We’ll also cover practical tips and troubleshooting to help you run your capsule filler safely and efficiently.

Let’s Start With Capsule Filling Basics

Before we talk about how to use a capsule filling machine, it helps to get comfortable with a few basics.

1. Know your empty capsules

First of all, an empty hard capsule has two pieces. A longer body holds the fill material, and a shorter cap snaps over the body to lock the capsule.

Next, you should be clear on what the capsules are made of. Capsule material is either animal-based, like gelatin, or plant-based, like HPMC.

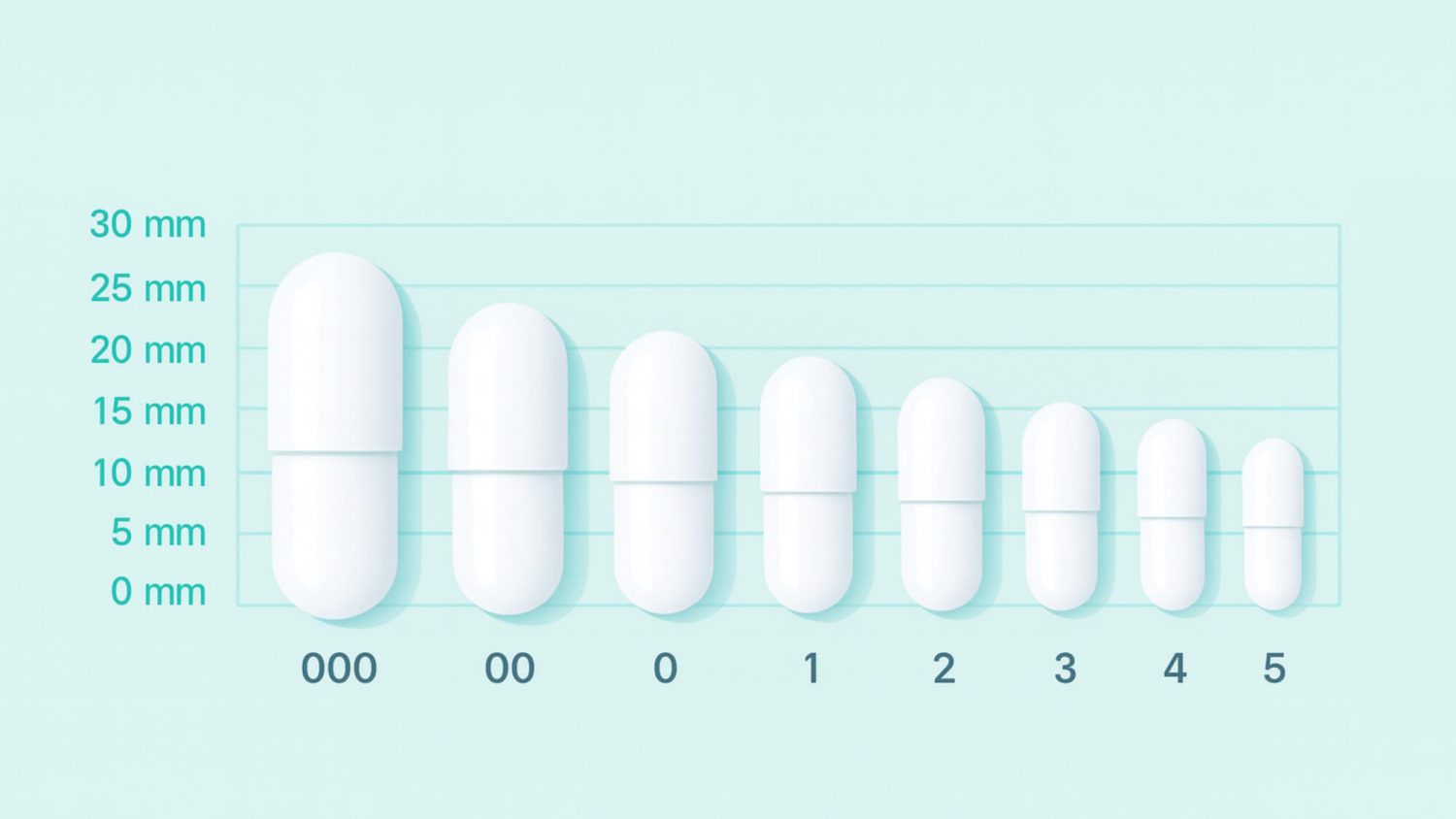

The common capsule sizes that can run into a standard capsule filling machine are 000, 00, 0, 1, 2, 3, 4, and 5, from the largest to the smallest. If you’re producing supplements, size 0 and size 00 are the most popular choices.

2. Understand the product that a capsule fill can work with

A wide variety of substances can be filled in capsules.

- Solid forms: Powders, granules, pellets, mini-tablets

- Liquid and semi-solid forms: Oils, suspensions, pastes, gels, non-aqueous solutions

- Combination: Various combos of the above

3. Learn the standard capsule filling process

No matter the machine type, the workflow is almost the same:

- Empty capsules are oriented.

- Caps and bodies are separated.

- Product is dosed into the capsule bodies.

- Caps are placed back on and locked.

- Filled capsules are discharged and checked.

Types Of Capsule Filling Machines

Generally, you’re choosing between three categories:

1. Manual capsule fillers: These are the simplest and most budget-friendly options. They’re often small tabletop units that work without electricity. Because every step is done by hand, production is slow.

2. Semi-automatic capsule filling machines: They usually have motorized or pneumatic systems to handle some parts of the capsule filling process. But you’ll still need an operator to do certain tasks like like opening and assembling the filling ring and moving it between stations.

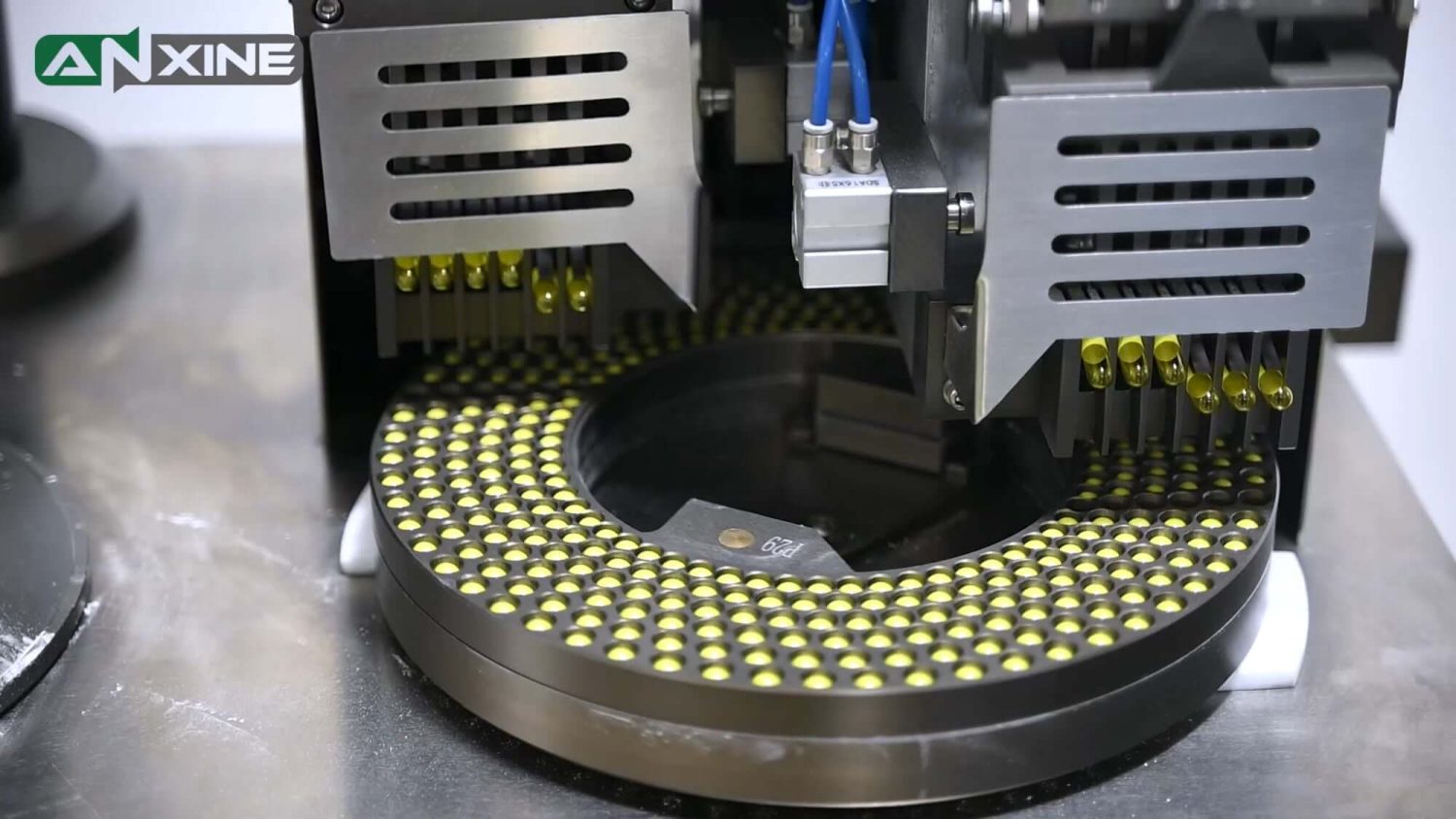

3. Fully automatic capsule filling machines: These units are big and sophisticated. They handle the entire capsule filling process in a continuous, automated cycle. Built with advanced controls and sensors, these machines ensure you can have consistent, high-quality finished capsules.

Quick Comparison: Manual vs Semi-Automatic vs Fully Automatic Capsule Filling Machines

| Manual Capsule Filler | Semi-Automatic Capsule Filler Machine | Fully Automatic Capsule Filler Machine | |

| Best For | – Very small-scale production – R&D – DIY supplement makers | – Small to mid-scale production – Growing businesses | – Large-scale manufacturing |

| Typical Output | 800 to 2,000 capsules/hour | 10,000-40,000 capsules/hour | 60,000-350,000 capsules/hour |

| Key Advantages | ✔ Affordable ✔ Easy to operate and maintain ✔ No power needed | ✔ Faster and more consistent than manual ✔ Some automated steps ✔ Flexible for multiple products | ✔ High throughput ✔ Minimal labor ✔ Highly precise and reliable dosing ✔ Ideal for continuous 24/7 production |

| Main Limitations | × Requires a lot of manual effort × Slower and less consistent | × Still requires manual involvement × Costs more than manual models | × The most expensive and complex × Longer training for setup, operation, and maintenance |

How To Use A Manual Capsule Filler Machine

Manual capsule fillers are straightforward, but you need some skill to get reliable fills.

Components You’ll Work With:

- Cap plate and body plate: Used to hold capsule caps and bodies

- Middle plate: The key part used in the locking step

- Alignment plate: Helps with loading empty capsules

- Tamper: Used to compact the powder

- Spreader: Pushes powder across the plate to top up the bodies

- Spill guard: Prevents powder from spilling out

Step-by-Step: Manual Capsule Filler Process

1. Load your empty capsules

- Set the alignment plate on top of the cap plate and pour in empty capsule caps.

- Gently shake both plates until each hole is filled with a cap. Then remove the excess caps.

- Separate the alignment plate and cap plate and set them aside.

- Take the body plate and place the alignment plate over it. Add empty capsule bodies.

- Give the plates a light shake so the bodies settle into the holes. Then take out the excess and set aside the alignment plate.

2. Fill capsule bodies with powder

- Set the spill guard over the body plate.

- Spoon some powder onto the plate. Then use the spreader to level out the powder until each capsule body is filled. Scrape off the excess powder, if any. Remove the spill guard.

3. Tamp the powder

- Press the tamper onto the the body plate to compact the powder inside each capsule body.

📍Repeat Steps 2 and 3 if the bodies are not full: Attach the spill guard, add more powder, and spread it evenly to top them up.

4. Lock the capsules

- Set the middle plate on top of the cap plate.

- Flip over both plates and attach them to the body plate.

- Press down firmly with your hands to snap the caps onto the bodies.

5. Remove the filled capsules

- Lift off the cap plate and collect all finished capsules from the middle plate.

How To Use A Semi-Automatic Capsule Filling Machine

Semi-automatic capsule filling machines combine automation with hands-on controls. They take over the key steps: capsule orientation, feeding, filling, and closing.

Main Components:

- Powder hopper: Holds the fill materials, not just powder

- Capsule hopper: Used to store empty capsules

- Orientation and feeding mechanism: Orients and loads empty capsules into the filling ring

- Filling ring: Consists of two discs and accommodates the empty capsules to be filled

- Filling head: Attached under the powder hopper to top up capsule bodies

- Peg ring: Made up of pins and used to close capsules

- Control panel/buttons/foot pedal: Used to automate some steps

Step-by-Step: How a Semi-Automatic Capsule Filling Machine Operates

1. Load empty capsules and powder into hoppers

- Most of the time, this part is done by hand. Some higher-end models can pair with feeders to help automate it.

2. Feed empty capsules

- Manually set the filling ring in place and get it ready for empty capsules.

- Press the buttons on the control panel to start feeding capsules.

- The orientation and feeding unit positions each empty capsule in the right direction and then sows it into the rotating filling ring.

3. Fill powder into bodies

- Once the filling ring is loaded with empty capsules, rotate it to separate the cap and body discs by vacuum.

- Set the cap disc aside and position the body disc under the filling head.

- Press the button to fill as the disc spins.

4. Close the capsules

- When filling is done, set the cap disc back onto the body disc.

- Manually move the reassembled filling ring to the closing station.

- Line up the filling ring’s holes with the peg ring pins.

- Press the button or use the foot pedal to start the pneumatic pressure. This forces the pins to push the bodies into the caps and lock the capsules.

5. Discharge the finished capsules

- Open the ring assembly to release the closed capsules and collect them in a bin.

How To Use A Fully Automatic Capsule Filling Machine

Fully automatic machines handle the entire capsule filling process with minimal labor. All you need to do is set the parameters and press the right buttons.

Core Components:

- Empty capsule and powder hoppers

- Capsule orientation and feeding unit

- Segments mounted on a turret

- Dosing and filling mechanism

- Closing system

- Rejection Unit

- Ejector system

- Human-Machine Interface

Step-by-Step: How to Run a Fully Automatic Capsule Filling Machine

1. Prepare and set parameters

- In an automatic capsule filler, empty capsules and powder are usually loaded into their hoppers by specialized feeders.

- Create a recipe and set up run parameters on the HMI.

2. Start the capsule filling cycle

- Hit the start button and let the machine run.

- As the turret indexes through each station:

- Capsules are oriented and fed into the segment bores.

- The segment opens to separate the caps and bodies.

- Premeasured powder is dosed into each capsule body.

- Filled bodies are pushed upward by pins to snap into caps.

- Faulty capsules are automatically rejected.

- Finished capsules are discharged from the machine.

3. Monitor the operation

- Watch for proper capsule separation and filling.

- Listen for any unusual noises.

- Check that the machine is running without any jams.

- Keep an eye on the HMI and watch for any alarms.

- Pay attention to the temperature and humidity of the production area.

Practical Tips for Better Capsule Filling Results

No matter what type of capsule filling machine you use, a few best practices can make the process smoother.

Here’s what experienced operators always pay attention to:

- Using free-flowing material can prevent uneven fills or machine jams.

- Capsules are sensitive to humidity, so try to keep temperature and moisture levels stable in your production area.

- Calibrate your machine on a regular schedule. This keeps dosing accurate and your final product consistent.

- If you are new to capsule filling, start with small test batches. It helps you get to know your machine.

- Record any adjustments you make during each run. These notes make troubleshooting much easier later.

- Make sure your machine is clean for each batch. Though powder residue is sometimes inevitable, cleaning in time can avoid cross-contamination.

Common Capsule Filling Problems And How To Fix Them

Knowing how to run a capsule filling machine is not enough. You also need to know how to fix the issues that come up along the way.

| Problem | What You’ll Notice | Likely Cause | How to Troubleshoot |

| Capsules not separating | Caps or bodies are not in their own segment bores | – Humid surroundings – Worn toolingWeak vacuum | – Reduce RH – Clean and dry capsules – Check tooling – Increase the vacuum pressure |

| Capsules not orienting correctly | Capsules sit upside down | – Capsule hopper jam – Worn orientation parts | – Clean hopper – Remove stuck capsules – Check the sorting components |

| Inconsistent fill weight | Weight varies from capsule to capsule | – Poor powder flow – Incorrect tamping depth – Uneven powder bed | – Sieve powders or add a flow agent – Adjust tamping pins – Level the powder bed |

| Underfilled capsules | Capsule bodies look visibly empty or light | – Not enough powder in the hopper – Low dosing volume | – Refill hopperIncrease dosing depth – Check the dosing disc for blockage |

| Overfilled capsules | Powder spills out of bodies | – Too much tamping – Incorrect dosing setting | – Reduce tamping stages – Adjust dosing volume |

| Capsules not locking properly | Bodies fail to snap into caps | – Deformed caps or bodies – Misalignment – Worn locking pins | – Replace capsules – Re-align tooling – Swap worn pins |

| Cracked or dented capsules | Shells are broken after closing | – Too much locking force – Misaligned segments | – Reduce locking force – Re-align upper and lower segments |

| Excessive dust buildup | Dust around the turret | – Powder is too fine – Weak vacuum system | – Adjust vacuum settings – Granulate powders |

| Too many rejects | Even good capsules are rejected | – Capsules not fully seated in the segments – Sensor errors – Incorrect rejection settings | – Re-align the segments – Re-calibrate or wipe clean the sensor if dusted – Check the machine settings |

| Machine stops frequently | Jams or alarms triggered | – Misaligned tooling – Low air pressure – Excessive dust – Motor overload | – Re-calibrate machine – Check the air supply – Clean key parts and components – Inspect motors |

Final Word

Starting from the basics of capsule filling to the different machine types, we’ve covered everything you need to feel confident using a capsule filling machine. With a little practice and regular care of your equipment, you’ll be filling capsules like a pro, whether you’re producing 500 or 500,000 at a time.

If you have any questions about capsule filling machines, contact us anytime! Our team at Anxine can help solve your problems quickly and offer you custom capsule filling solutions.