Are big orders piling up while your lines crawl along? If you’ve ever had to turn down business because you simply couldn’t crank out tablets fast enough, you’re in good company. Many small and midsize manufacturers hit that ceiling sooner than they expect. The fix isn’t always a bigger factory—sometimes it’s the right piece of equipment: a high-speed rotary tablet press.

Below you’ll find a nuts-and-bolts look at what this machine does, the variations on the market, and how to pick one that fits your needs.

What Exactly is a High-Speed Rotary Tablet Press?

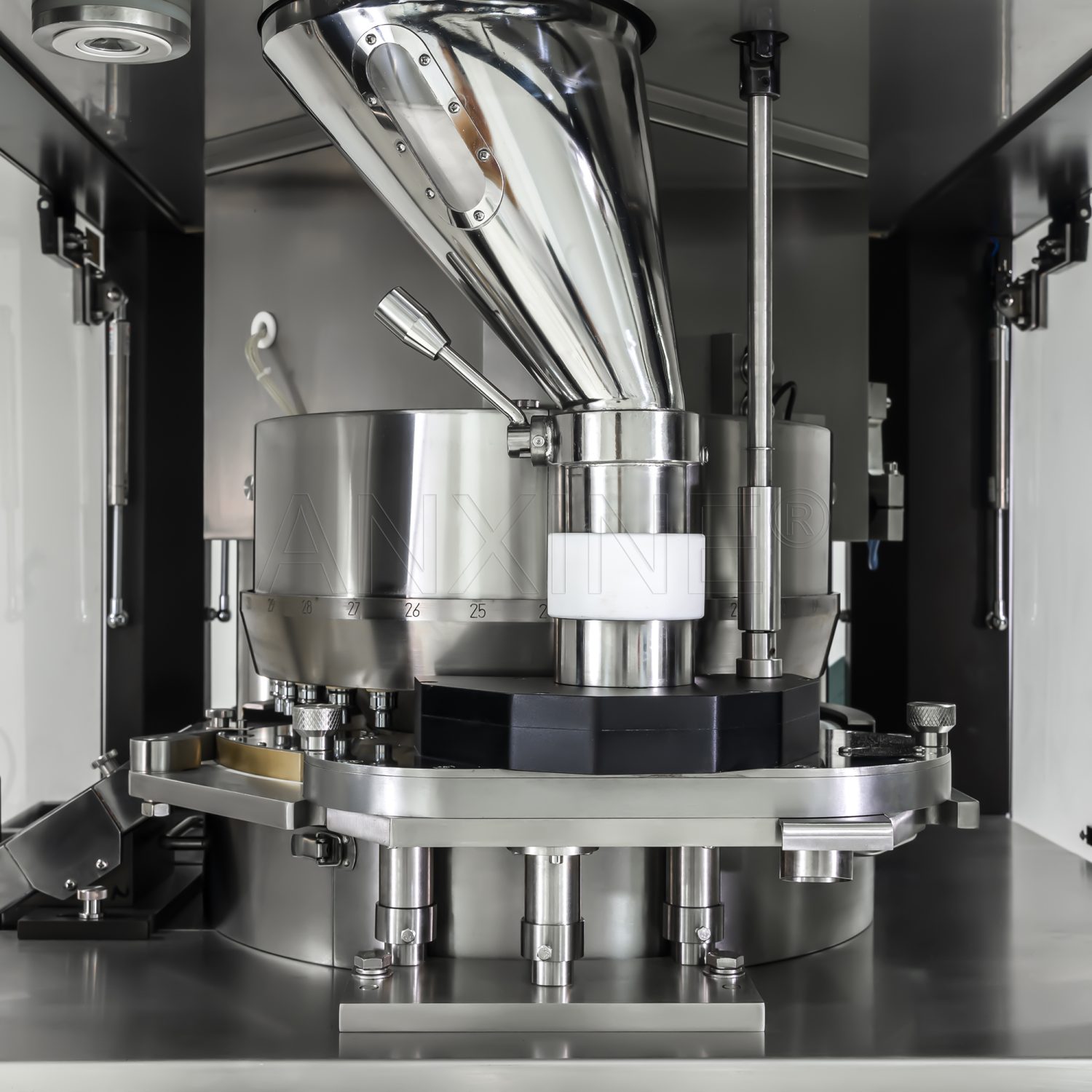

At its core, a high-speed rotary tablet press is an advanced piece of tablet compression equipment. It can create tablets at an incredible rate.

This type of tablet press boasts a rotating turret with multiple pairs of punches and dies. This allows for a continuous, high-speed tablet compression process.

So, how does a high-speed rotary tablet press work? It performs several actions:

- Filling: Powder flows from a hopper through a feed frame. This component ensures a consistent material supply into the die cavities. A force feeder is often used.

- Metering: Uniform dosing is important. This step accurately measures and scrapes off excess powder for each dose.

- Compressing: It happens in two key stages.

a) Pre-compression

First, the top and bottom punches move towards each other to gently press the powder. This mild squeeze forms a slug and pushes out any air trapped in the powder

b) Main compression

Next, strong rollers press the punch pair together with much more force. This squeezes the powder slug tightly into a solid tablet. - Ejecting: Now the compression is done. An ejection cam raises the lower punch. The finished tablet jumps out from the die onto a take-off blade, which guides it into a discharge chute.

Types of High-Speed Rotary Tablet Press Machines

Apparently, all rotary tablet press machines operate on a similar principle. The difference lies in their configurations. Let’s check out the main types you’ll encounter on the market:

Single-Sided Rotary Tablet Press

This is the most common type for small to medium-scale production. It features a single set of compression rollers and one discharge chute. This type is a reliable workhorse for manufacturing standard tablets.

Thinking about transitioning from small scales to full commercial runs? This high-speed rotary tablet press is an excellent choice.

Double-Sided Rotary Tablet Press

This machine typically has two sets of everything—two feeding hoppers, two sets of compression rollers, and two discharge chutes. All these components operate on opposite sides of the turret.

This design essentially doubles the output of a single-sided press of a similar size. It can handle complex tablet shapes and larger batch sizes.

Multi-Layer Rotary Tablet Press

This type is a specialized high-speed rotary tablet press machine. It can produce tablets with multiple distinct layers.

If you’re combining different active ingredients that may be incompatible, check out this machine. It’s also often used to create controlled-release formulations, such as cold-and-flu tablets.

| Style | Best For | Quick Take |

| Single-Sided | Small to mid-range batches | One feed hopper, one discharge. A straightforward workhorse for companies moving up from single-station units. |

| Double-Sided | High volume commercial runs | Two hoppers, two discharge chutes. Doubled output—often 400k+ tablets per hour. |

| Multi-Layer | Combo or time-release products | Compresses two or three layers in one pass. Great for cold and flue formulas or chewables with separate flavor layers. |

Feature Checklist: What to Look for When Buying a High-Speed Rotary Tablet Press

Still feel overwhelmed by choosing the best fit for your tablet manufacturing needs? This feature checklist can help.

I. Production Capacity & Performance

- [ ] Maximum Output (Tablets/Hour):

- Does this meet your current and future production needs?

- [ ] Machine Type:

- [ ] Single-Sided

- [ ] Double-Sided

- [ ] Turret Specifications:

- Number of Stations:

- Maximum RPM: _

- [ ] Compression Force:

- Maximum Main Compression (kN): _

- Maximum Pre-Compression (kN): __

- [ ] Dwell Time:

- Is the dwell time long enough for the formulations you want to use?

- [ ] Feeder System:

- [ ] Gravity Feeder

- [ ] Force Feeder

- Is the feeder design suitable for your powder characteristics?

- Can the feeder be easily disassembled and cleaned?

II. Tooling & Tablet Capability

- [ ] Tooling Type Compatibility:

- [ ] B

- [ ] D

- [ ] BB

- [ ] DB

- [ ] Other: _

- [ ] Interchangeable Turret:

- [ ] Yes

- [ ] No

- [ ] Maximum Tablet Dimensions:

- Diameter (mm): _

- Depth of Fill (mm): __

- [ ] Multi-Tip Tooling Compatibility:

- [ ] Yes

- [ ] No

III. Automation & Control System

- [ ] Control Interface (HMI):

- Is the machine control interface user-friendly?

- [ ] In-Process Controls (IPC):

- [ ] Automatic Tablet Weight Control/Adjustment

- [ ] Automatic Tablet Hardness Monitoring

- [ ] Automatic Tablet Thickness Monitoring

- [ ] Automatic Tablet Rejection System:

- Does the system reliably reject out-of-spec tablets?

- [ ] Data & Recipe Management:

- [ ] Ability to store and recall product recipes

- [ ] Remote Access:

- [ ] Remote monitoring capability

- [ ] Remote diagnostics and support

IV. cGMP Compliance & Cleaning

- [ ] Construction Materials:

- Are all product contact parts made of SS 316L?

- [ ] Design & Accessibility:

- Are surfaces smooth and polished, with no crevices, for effective cleaning?

- Is there easy access to the compression zone for cleaning and inspection?

- Are parts like feeders and discharge chutes easy to remove?

- [ ] Dust Extraction:

- Does it include an efficient dust extraction system?

V. Safety Features

- [ ] Guarding:

- Are all moving parts protected by interlocked safety guards?

- [ ] Emergency Stops:

- Are E-stop buttons clearly visible and easily accessible?

- [ ] System Protection:

- [ ] Mechanical Overload Protection

- [ ] Electronic Overload Protection

- [ ] Alarms:

- Does the system have visual and audible alerts for malfunctions?

- [ ] Noise Level:

- Does the tablet press operate with low noise?

VI. Maintenance & Manufacturer Support

- [ ] Ease of Maintenance:

- Are routine lubrication points easily accessible?

- Is the process for changing punches and dies straightforward and quick?

- [ ] Manufacturer Support:

- Is responsive technical support available?

- Is field service readily available in your region?

- [ ] Spare Parts:

- Are critical spare parts readily available from the manufacturer?

- [ ] Documentation & Training:

- [ ] Are comprehensive operational and maintenance manuals available?

- [ ] Is operator and maintenance training included?

How to Find the Ideal High-Speed Rotary Tablet Press Manufacturer

Choosing where to buy your tablet press is as big a deal as choosing the machine itself. It’s not just making a one-time purchase. A good supplier will be there for you long after the sale.

Here’s what to dig into when you talk to potential suppliers:

1. Check Their Reputation

- Look for specialists in tablet compression technology, not just a general equipment dealer.

- Read their customer reviews. What are real people saying about them?

2. Grill Them on After-Sales Support

- Ask them point-blank: How fast will you get back to me if my machine goes down? Is that response time guaranteed in writing?

- Find out: Can you send a technician to our plant for on-site help when we need it?

3. Make Sure They Stock Spare Parts

- Confirm: Do you keep a ready supply of common parts like punches, dies, and seals?

- Ask: How quickly can you ship them out?

4. Understand the Training & Installation

- Clarify: Does the price include installation and training for operators?

- Ask about advanced training: Do you offer more in-depth maintenance training for our technical staff?

5. See if They Can Handle Custom Jobs

- Ask: Can you create custom punches and dies for our specific designs?

- Find out: Will you help us tweak the machine’s settings to get our unique product perfect?

Frequently Asked Questions (FAQs)

- Q1: How many tablets can a high-speed rotary press produce?

If you’re an SMB, many machines out there can produce from 50,000 to over 400,000 tablets per hour. However, the actual output will always depend on the tablet’s design and formulation.

- Q2: Can I use the same machine for different tablet sizes?

Yes. Go for a model with an interchangeable turret. Or pick a tablet press that supports different standardized tooling sets, like TSM or EU standards. You can change the punch-die set to create various tablet formats.

- Q3: What sets a rotary tablet press apart from a single-punch press?

The high-speed rotary tablet press features a turret containing multiple stations. The design enables a continuous, high-volume production. A single-punch press has only one station. It works more slowly and is best for lab-scale use.

- Q4: How much maintenance does a high-speed rotary tablet press machine require?

A high-speed rotary tablet press needs regular care to work well. You should clean it every day to remove powder dust, lubricate moving parts weekly to prevent wear, and check punches and dies often for any damage. Following a routine maintenance schedule helps avoid breakdowns and keeps the machine running smoothly.

Ready to Step Up? Anxine is Here to Help!

When choosing a high-speed rotary tablet press, just keep in mind that there are many things to think about—capacity, speed, compression force, tooling, maintenance, and more. But you don’t have to do this alone.

At Anxine, we’re here to guide you every step of the way. Whether you need advice, a custom solution, or ongoing support, we’ve got your back.

If you’re ready to move forward, reach out to us today. We’d love to help you find the perfect tablet press for your needs.