An automatic capsule filling machine plays a key role in modern pharmaceutical and supplement production. They fill and seal capsules accurately and quickly. Many buyers focus on output or accuracy, but the working principle often decides whether the machine fits real production needs. A clear understanding of how the machine handles capsules helps reduce setup issues and quality risks. This article explains the working principle of an automatic capsule filling machine in a clear and practical way. So you can know how each step works inside the machine.

Basic Structures of an Automatic Capsule Filling Machine

An automatic capsule filling equipment is made up of several functional units. Each unit performs one specific task and works together to complete the filling process.

- Capsule feeding system. It moves empty capsules from the hopper for processing. This system ensures a stable supply and prevents stacking or blockage.

- Capsule separation unit. This part separates the capsule body and cap for filling. Accurate separation is necessary to avoid damage and lead to smooth filling.

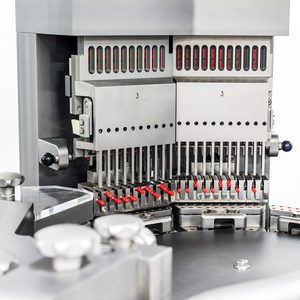

- Filling station. This is a key part of the capsule filling machine. It fills capsules with powder, pellets, or granules accurately. The part controls the fill depth and weight.

- Closing unit. It is used to seal the capsule body and cap after filling. Controlled pressure could lock the capsule securely.

- Discharge system. This system transfers finished capsules out of the machine. Qualified capsules move to the collection for further processing.

What is the Automatic Capsule Filling Machine Working Principle?

The working principle of an automatic capsule filling machine is to move empty capsules step by step through orientation, separation, filling, locking, and ejection stations on a rotating turret. At each station, mechanical parts and a vacuum system automatically position, open, dose, close, and discharge capsules for production. After operators pour the powders and capsules, machines work by itself from capsule orentation to ejection. An automatic capsule filler greatly improves efficiency and saves much human effort. Most models are suitable for different capsule sizes from 000 to size 5. Some models can handle 24,000 capsules per hour.

Here is a video to show how it performs. With a basic knowledge of key parts, let’s see how a fully automatic capsule filler works in detail.

How Does an Automatic Capsule Filling Machine Orient Empty Capsules?

Before empty capsules are filled, they must be oriented in a consistent direction. In some cases, capsule rings are designed for orientation with brush wheels or airflow. But the most common method uses a multi-channel limiting structure. In this structure, capsules are first poured into the capsule delivery plate. This part contains multiple circular channels. Each channel allows only one capsule to pass through. And it includes spring-loaded retaining parts at the lower section. This design ensures that a single capsule is released at the correct time in a controlled manner.

During operation, the delivery plate moves in a controlled vertical motion. Capsules enter the channels and they are temporarily held by the spring parts. When the plate moves downward, the springs release the capsules. Then the capsules fall freely at a controlled speed and direction. At this stage, the capsule may fall with the body end or the cap end facing downward.

Next, horizontal and vertical guiding forks are used to correct the direction. The horizontal fork contacts the middle section of the capsule body. Because the body has a smaller diameter and a heavier weight than the cap, it is easier to capture. The capsule is then guided with the body leading forward. Next, a vertical fork performs a final adjustment. It uses gravity to let all capsules fall with the body facing downward for the next station.

How Does Vacuum Capsule Separation Work?

At this stage, the oriented capsules are already seated in the capsule segment. The capsule caps are aligned with the upper segment, and the capsule bodies are supported by the lower segment. Then, the capsule segment moves into position under the vacuum system. A vacuum plate rises and contacts the upper segment. Due to the suction force, the capsule caps are held firmly in the upper segment. And the capsule bodies remain supported in the lower segment.

When the upper and lower segments move apart, the capsule caps are retained by vacuum. Meanwhile, the capsule bodies move downward to the filling station. After separation, the upper and lower segments are transferred to different stations for filling or closing.

How Does the Filling System Work?

After separation, it is time for filling. At this stage, the machine dispenses a preset amount of medication into each empty capsule. The filling method depends on the machine design and the material properties. In automatic capsule filling models, the most common filling methods are the tamping pin and the dosator filling system.

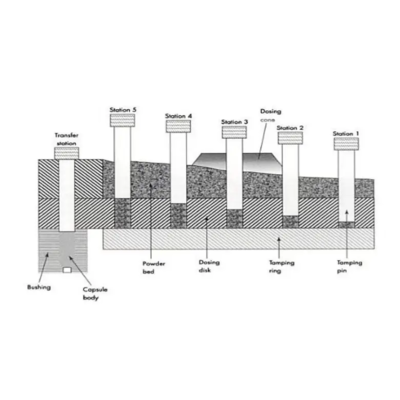

Tamping Pin Filling

It uses a rotating dosing disc and several tamping pins to fill capsules. It fills capsules through step-by-step powder compaction. At first, powder flows into the dosing disc. A series of tamping pins then compresses the powder inside the disc holes in multiple stages. This process forms a compact powder slug with the preset depth as required.

After compaction, the dosing disc moves to align with the capsule segment. Then, the powder plug is transferred into the capsule body. This system is suitable for powders that have good flowability and stable bulk density. Now tamping pin filling system is the most popular filling method in the market. Many fully automatic capsule fillers, like NJP models, use this way for operation.

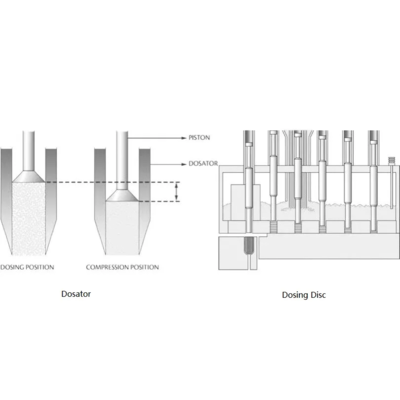

Dosator Filling

In this system, the dosator tube enters the powder bed to a required depth. While the tube remains in the powder, a piston compresses the powder into a slug. After the powder plug is formed, the dosing tube moves to the filling position. The piston then pushes the powder plug out of the tube and into the capsule body. This method is suitable when you want to fill DPIs.

How to Seal Capsules Tightly?

When the filling process is finished, the capsule bodies and caps move to the locking station. The upper and lower capsule segments match accurately to be locked. Next, the machine applies pressure from above while the capsule body is supported from below. This pressure pushes the cap and body together until they lock firmly. Once the locking step is finished, the capsule is fully closed and ready for discharge.

How to Get Capsule Ejected from the Machine?

After the capsules are fully closed, they could be discharged. The machine uses a push rod or air pressure to release the finished capsules from the segment holes. The capsules then fall smoothly into a collection container for further processing.

Get High-quality Automatic Capsule Fillers from Anxine

A good machine is highly related to a reliable supplier. As a leading machine manufacturer in China, we have helped thousands of clients to get good equipment. We offer different types of automatic capsule filling machines, as well as the pill tablet press, polishing machine and liquid filler. Our machines all meet related regulations like GMP standards. We also have a professional technical team. They will help you solve problems from design to packaging. Contact us now to get fully automatic capsule fillers for better performance.