If you’re planning to work with capsules, you’ve probably heard people say that capsule filling machines are “highly versatile.” And they’re right.

Maybe you are building a supplement brand. Or perhaps you run a pharmaceutical facility. A capsule filling machine quickly becomes something you simply can’t do without.

So how versatile are they, really? In this post, we’ll take a closer look at these incredible machines. You’ll learn exactly where capsule filling machines are used, what kinds of products they handle, and how to match their uses to your business in real life.

What A Capsule Filling Machine Actually Does

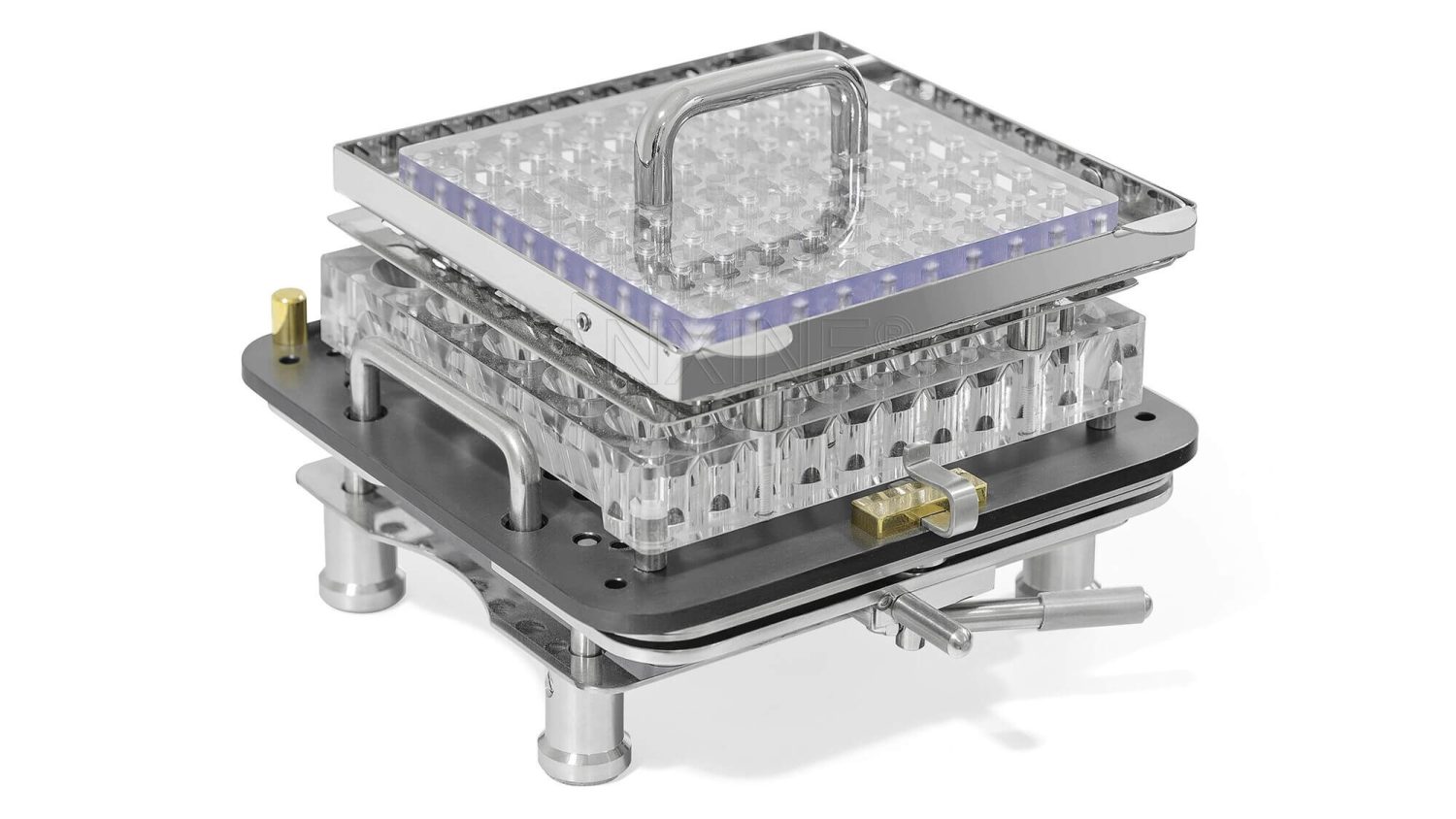

In plain language, a capsule filling machine’s job is to fill empty capsules with your formula in a fast, labor-saving way. You don’t need to open each capsule by hand and add your product scoop by scoop. Industrial models do this at impressive speed and accuracy. They often handle tens of thousands of capsules per hour in continuous motion.

Let’s see what a capsule filling can do for you:

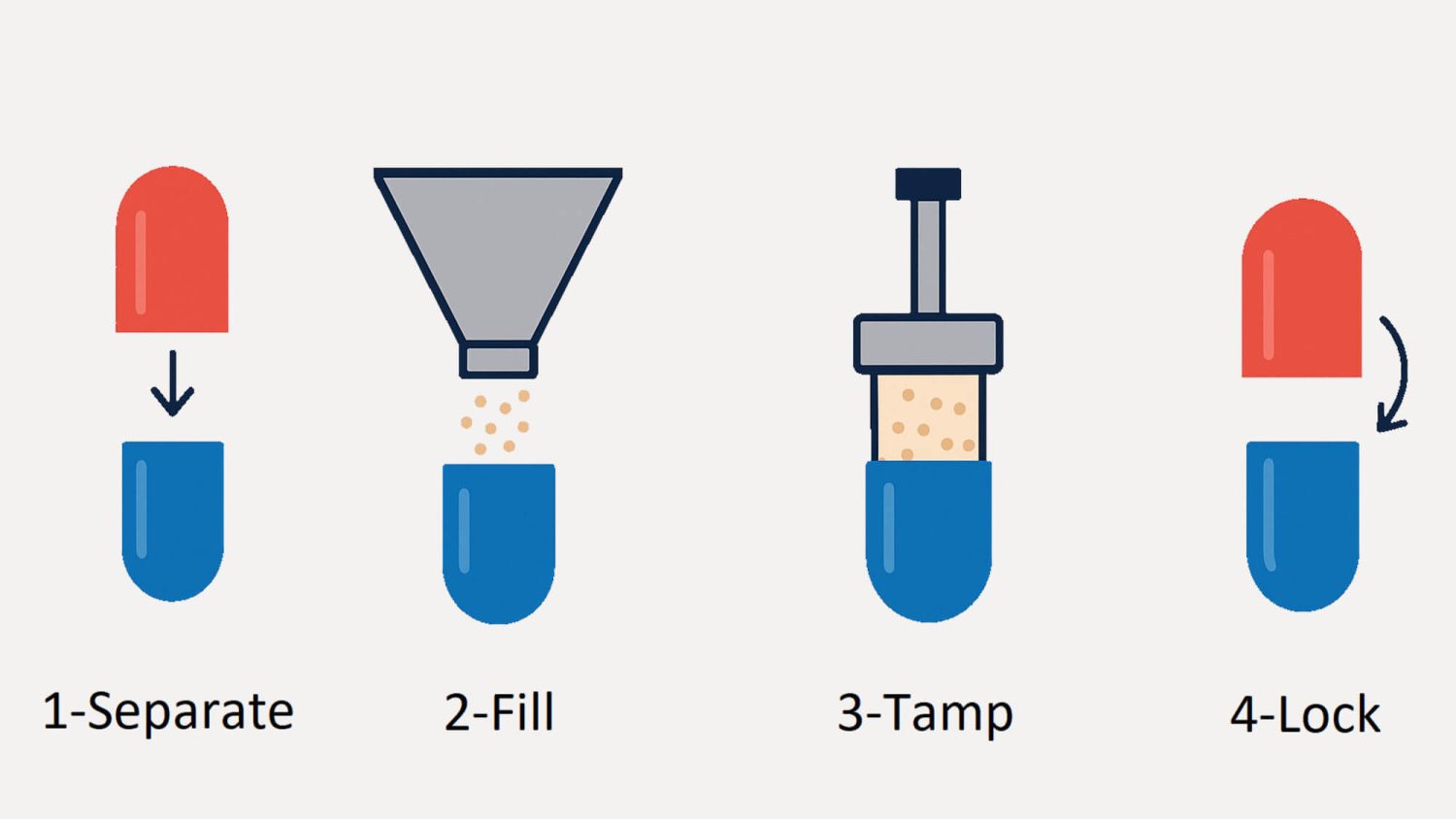

- Separates the capsule cap and body

- Doses the fill material accurately

- Packs the fill to the required weight

- Closes and locks the capsule

- Ensures uniformity from capsule to capsule

The core workflow is similar whether you are using a manual tray, a semi-automatic capsule filler, or a fully automatic system. The main difference is the speed, the level of automation, and how much flexibility you have for different products.

Key Capsule Filling Machine Uses Across Industries

Capsule filling machines aren’t one-industry wonders. They show up anywhere capsules are used as a dosage form.

Pharmaceutical Manufacturers

It’s no surprise that capsule filling machines are the essential equipment in this field. Simply filling capsule medicines by hand can cause a series of problems. A capsule filling machine helps with precise dosing and tight quality control over your prescription and over-the-counter drugs.

Pharma companies also love the versatility of capsule fillers. A single machine can often handle capsule sizes from 000 to 5 and different formulations. This means if you want to add a new dosage strength in capsule form, you can adjust your filler rather than buy a whole new setup.

Common uses include:

- Large-scale production of generic and branded drugs

- Small series for specialty therapies

- Clinical trial batches with different dose strengths

- Compounding work in hospital and community pharmacies

Nutraceutical & Dietary Supplement Brands

These are among the biggest users of capsule filling machines. Many of the wellness products you see on store shelves today come in capsule form. And just like medicines, taking too much of a supplement can be risky. Capsule filling machines help these brands deliver consistent, accurate doses in every capsule.

Nutraceutical and supplement brands often need fast changeovers. They handle a wide range of products, smaller batch sizes, and a fast-moving market that constantly demands new launches. That’s why automatic capsule filling machines are so common in this space. They make it much easier to switch quickly from one product to another.

Common uses include:

- Vitamins and minerals

- Botanical extracts

- Sports nutrition formulas and nootropics

- Beauty from within and collagen products

Herbal and Traditional Medicine Producers

Most herbal supplements and traditional Chinese medicine are also sold as capsules. Why? Because putting ground herbs and plant extracts into capsules makes them easier to dose and take. After all, not many consumers are excited about sipping a bitter herbal concoction.

Besides, some herbal powders are sensitive, like chamomile and dandelion root. It’s difficult to compress them into tablets. Capsules give them a gentler option.

Typical uses include:

- Fine herbal powders that tend to cap or laminate in tablet presses

- Moisture-sensitive or aromatic plant extracts

- Custom blends for health shops

Veterinary and Animal Health Products

Pets and livestock sometimes need medicines or supplements in pill form, and capsules can be an easy way to give them. Capsule machines for vet products work just like those for human meds. The key is that the machine ensures every capsule gets the right dose of active ingredient, whether the patient is a person or an animal.

Examples include:

- Probiotics for pets

- Joint support supplements

- Deworming medications

- Nutritional capsules for farm animals

Contract Manufacturers

Many brands don’t have their own factories, so they work with contract manufacturers (CMOs) to make their products. These manufacturers rely heavily on capsule filling machines. One day they might be running probiotic supplement capsules, and the next day a pain relief drug. That’s why their capsule filling equipment has to be versatile and efficient enough to switch between jobs quickly.

Uses for CMOs include:

- Running different capsule sizes

- Handling multiple formulas every week

- Producing short-run batches

- Maintaining uniform quality for many clients

R&D Labs and Clinical Trial Units

When researchers formulate a new drug or supplement, they often need to prepare capsules for testing. Doing this by hand would be slow and easy to mess up. Capsule fillers help labs ensure each capsule has the exact test dose. This is essential for getting reliable trial data.

Often, labs use manual capsule fillers for very small runs, or a compact semi-automatic machine for a bit more volume. Many manual capsule fillers are built specifically for R&D and pilot manufacturing.

Common applications include:

- Early-stage formulation testing

- Bioavailability studies

- Pilot batches

- Clinical trial sample production

Application Of Capsule Filling Machine By Product & Formulation

One reason capsule filling machines are so popular is that they don’t just handle simple powders. These machines can work with various formulation types. Here are the main kinds of fills that you can run on a capsule filling machine:

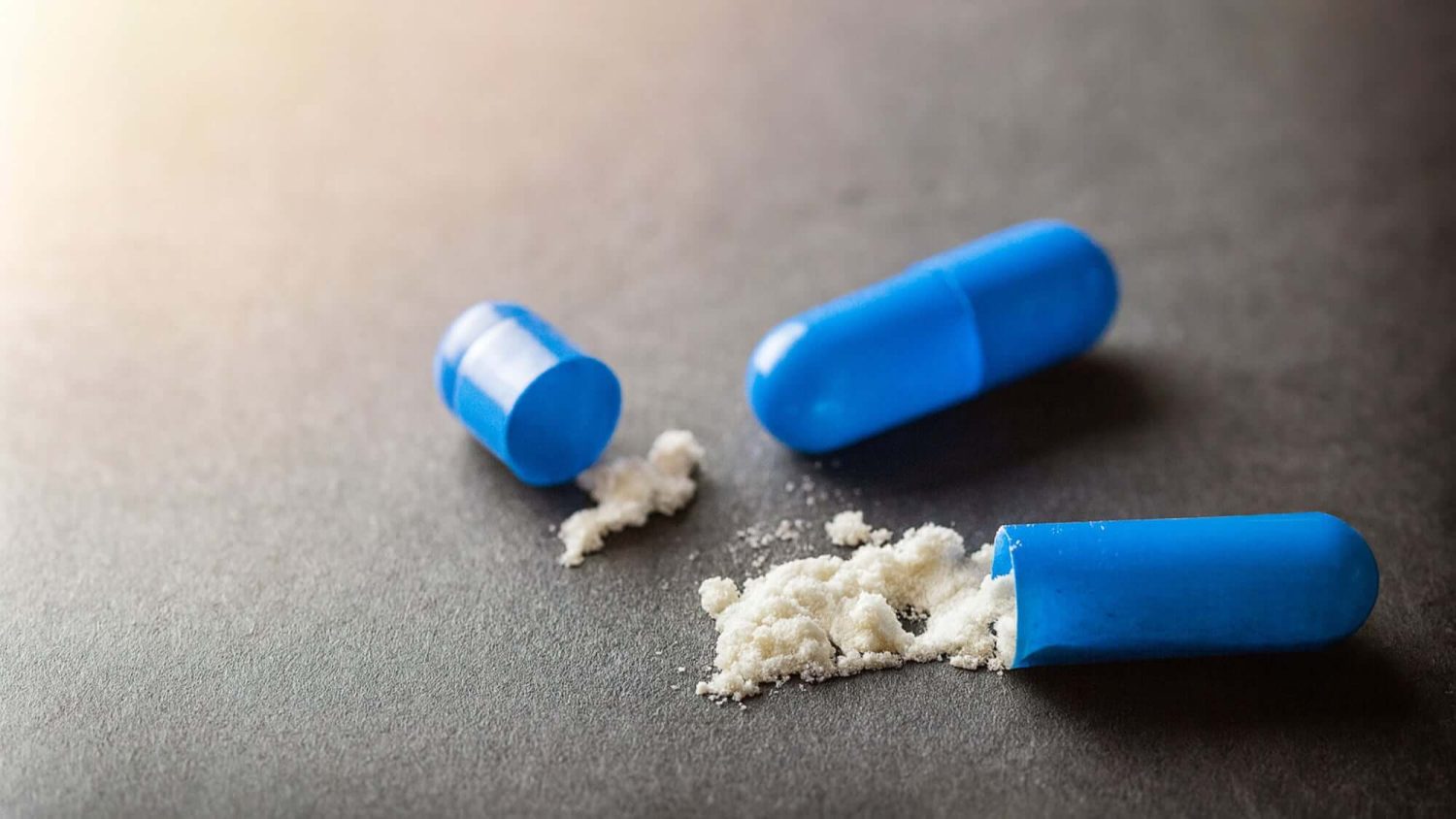

Powders and Granules

This is the most common application of a capsule filling machine. Depending on the flow properties, manufacturers may use the dosator or tamping pin method to achieve consistent fill weights.

Typical examples:

- Straight APIs blended with excipients

- Premixes of vitamins, minerals, and herbal ingredients

- Granules designed for better flow or controlled release

Pellets and Multi-Particulates

Pellets are small, spherical beads often used in controlled-release drugs. So, pellet filling is a common need. A single capsule might hold dozens of these tiny pellets to deliver the full dose. Often, the capsule filling machine uses a slower speed or a modified dosing disc to fill pellets into capsules without bouncing out or getting stuck.

Typical uses:

- Enteric-coated or sustained-release pellets

- Bead-based supplements

- Combination of different pellet types in one capsule

Liquids and Semi-Solids

You might not think of putting liquids into a hard capsule, but it’s definitely a thing! When a capsule filler is equipped with a servo-controlled pump, anti-drip nozzles, and banding or sealing features, it can handle liquids and even semi-solid pastes.

Common applications:

- Oil-based formulations like fish oil or CBD oil

- Lipid-based drug formulations

- Nutraceutical liquid extracts

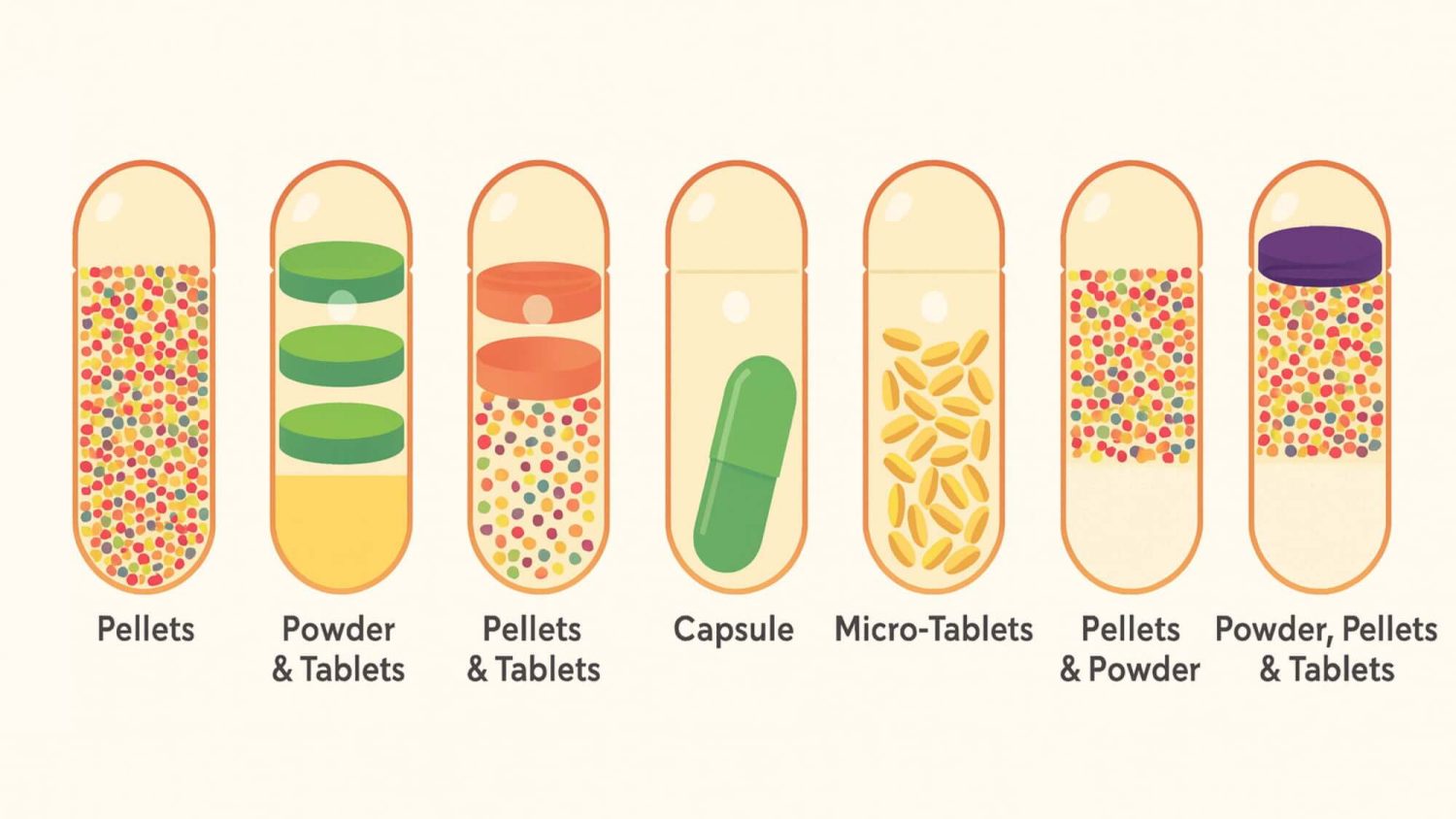

Combination Fills

A capsule is like a mini container. It’s capable of “mixing and matching” different ingredients inside a single shell. And today’s capsule filling machines won’t let you down. Some of them are built for this kind of work. Some models can fill up to three or four different components in one capsule.

Examples include:

- Powder plus pellets for immediate and extended release

- Layered pharmaceutical dosing

- Beads plus mini tablets for tailored profiles

- Capsule-in-capsule for mixing incompatible drugs

Capsule Filling Machine Uses for Every Scale

Capsule filling machines come in all shapes and sizes. The right one for you depends largely on your production scale.

Small Scale and Personal Use

Manual capsule fillers are the simplest kind. They’re just a small tabletop device with trays and a hand-operated mechanism. If you want to fill 50 or 100 capsules at a time by hand, that’s the idea.

Small businesses, pharmacies, R&D labs, or even homemakers can use manual fillers. They’re inexpensive, easy to use, and don’t need any electricity.

Mid-Scale Production

Let’s say that you plan to move beyond a home-based setup. You need semi-automatic capsule filling machines. They can often produce 10,000 to 40,000 capsules per hour. That is a huge leap from manual methods. The machine also ensures each capsule is filled accurately.

Typically, an operator loads empty capsules into the machine and starts the filling cycle, but the machine will handle dosing the powder and even locking the capsules automatically.

Semi-automatic machines are valued for being cost-effective and relatively easy to use. Maintenance and cleaning are simpler than for fully automated lines too.

High-Volume Manufacturing

In industries like pharma, having a fully automatic encapsulation line is standard for any high-volume drug. The same goes for the largest supplement brands and contract manufacturers.

The output can range from around 60,000 capsules/hour on smaller models to over 350,000 capsules/hour on the fastest machines. If you need to produce millions of capsules a week, an automatic line is the way to go.

Of course, this comes with a price. Fully automatic capsule filling machines cost a lot more upfront and require proper training to operate and maintain. But the payoff is usually worth it for large volumes.

How To Match Capsule Filling Machine Uses To Your Business

If you are reading this as a pharma or supplement brand owner, you are probably wondering: “Which capsule filling machine matters most for me?”

Here is a quick way to think about it:

- You are doing very small batches or early product testing

- A manual capsule filler is usually enough to get started.

- You have a few solid products and regular orders, but volumes are still modest

- A semi-automatic capsule filling machine gives you a big boost in efficiency without the cost of a full automatic line.

- You’re running multiple products at commercial scale or planning several capsule lines

- A fully automatic capsule filling machine with suitable dosing systems and tooling is usually the most cost-effective long-term choice.

As a manufacturer and supplier of capsule filling machines, Anxine’s job is to help you match your current and future needs with the right equipment. That means looking at your formulations, capsule sizes, regulatory needs, and growth plans, then recommending a setup that will not only work today but still make sense when your volumes are much higher.

If you are considering your next step with capsules and want help evaluating the best application of capsule filling machine for your products, reach out to us today!