NOTICE

- The following procedures are intended for Anxine equipment only. For other brands, refer to the original manufacturer’s instructions.

- Always disconnect the power supply before performing maintenance, cleaning, or mold changeover.

- Only trained and authorized persons are permitted to work on the equipment.

- Your equipment may vary from images or videos due to ongoing upgrades.

- If any part of this guide is unclear, contact Anxine for technical support before proceeding.

How to Use the ZP-9 Tablet Press?

Click to view the ZP-9 tablet press.

Step 1: Open the hopper lid and load the powder. Ensure the powder level is within the operational range.

Step 2: Power on the system. The control panel lights up. Adjust the Left and Right handwheels to set the tablet thickness and filling depth.

Step 3: Press RUN to start. Turn the black knob to set the turret speed.

Step 4: Formed tablets are ejected and guided by the take-off blade to the discharge chute. Press STOP to halt the machine.

How to Use the ZP-D Tablet Press?

Click to view the ZP-D tablet press.

Step 1: Plug the industrial power cable into the large red socket located on the side of the machine.

Step 2: Open the top hopper and pour in powder or granules using a clean scoop.

Step 3: Release the emergency stop button.

Step 4: Turn on the main power switch to activate the control panel.

Step 5: Adjust the rotation and feeding speed. Press RUN. Press the forced feeder switch button.

Step 6: Once the settings are confirmed, the machine begins working. The upper and lower punches move vertically to compress the powder within the die.

Step 7: The completed tablets are ejected from the die cavities and slide down the discharge chute into a collection container.

How to Use the ZP-H High-Speed Tablet Press?

Click to view the ZP-H tablet press.

Step 1: Load material into the hopper located at the top of the machine.

Step 2: Pull the manual lever on the side of the hopper. Material flows from the hopper into the force feeder.

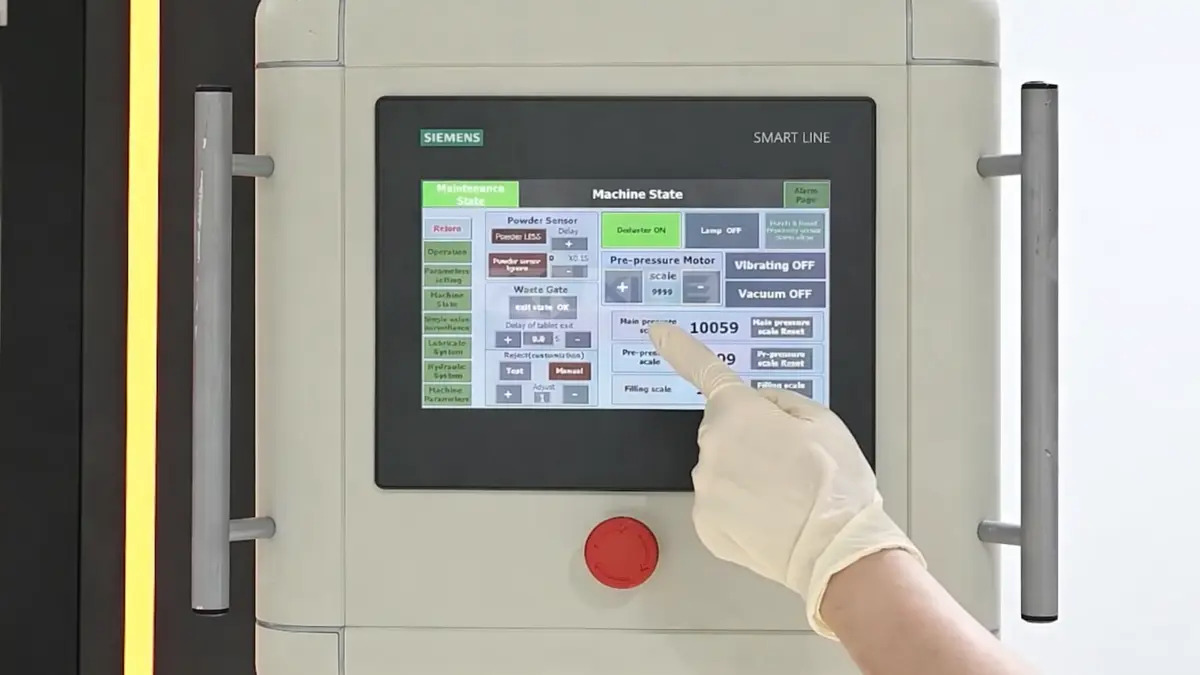

Step 3: Use the touchscreen to set up the press.

- MACHINE STATUS screen: Set the compression force. Turn on the dust extractor.

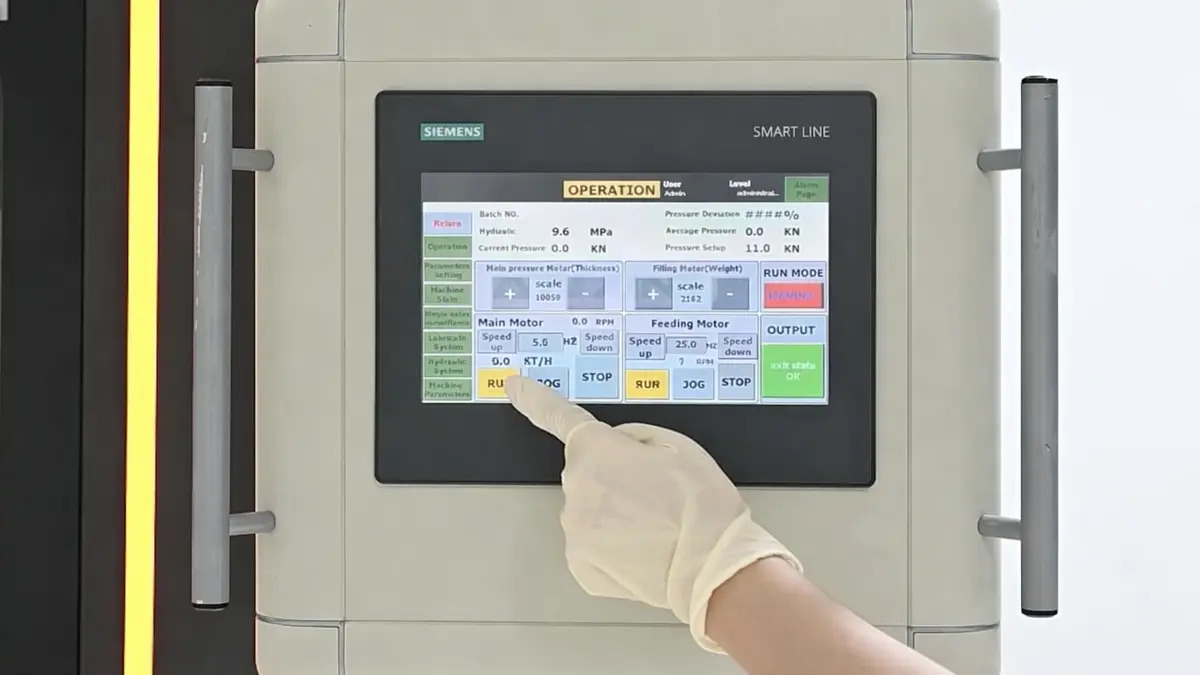

- OPERATION screen: Adjust motor settings. Press RUN to start the compression cycle.

Step 4: Observe the press as it runs.

Step 5: Inspect the finished tablets that exit through the discharge chute. Defective ones are rejected at the same time.