When powders do not blend properly, it can throw off everything that comes after it, costing you time and money. This is a problem a lot of manufacturers face. The tricky part is choosing the right mixing machine.

If you’re just in the middle of such a struggle and looking for a proven mixing solution, the ribbon blender is worth a look.

Here, we’ll talk about what a ribbon blender is used for, what it does well, what it falls short, and what to watch for when buying. After reading, you’ll have a clear picture of how it could improve your mixing step.

What Is a Ribbon Blender?

A ribbon blender is an industrial mixing machine designed to blend dry powders, granules, and even small amounts of liquids into a uniform mixture.

Typical industrial ribbon blenders have a horizontal, U-shaped trough. They get the name from the ribbons sitting on a central shaft. These metal ribbon-shaped blades rotate and sweep through the product to get a good mixing in a short time without pockets of unmixed ingredients.

So, how do you know you’re getting a “good mix” in a ribbon blender?

You might’ve come across the term “homogeneous mixing” when you read technical papers about ribbon blenders. In plain English, it means your material is evenly mixed everywhere.

Signs your ribbon blender is doing a solid job:

- Every scoop has the same color, density, or flavor

- Stable tablet hardness and weight

- Fewer rejected batches and less rework

Most ribbon blenders are batch machines. You charge the full recipe, blend for a set time, sample for quality, then discharge to the next step.

Many pharma and nutraceutical producers like ribbon blenders. No matter what you produce, the machine can ensure the same amount of actives in every dose. They’re versatile machines. You can use them for vitamin premixes and powder blends for many common capsules and tablets. They’re also more cost-effective and mechanically simpler than other complex mixers. And in pharma and nutraceutical plants, they’re usually easy to scale up as production grows.

Where A Ribbon Blender Fits In Your Line

In some cases, uneven mixing can also be a line setup issue. When your ribbon blender is installed in the wrong place, the blend quality can suffer. If you’re new to the setup, here’s a common production sequence to follow.

⚙ A common pharma sequence might look like:

Milling and sieving → Ribbon blender → Intermediate storage → Tablet press or capsule filler → Coating and packaging

⚙ For many nutra powder products:

Raw material weighing → Ribbon blender → Screening (if needed) → Filler for jars, bags, or sachets

Key Parts of an Industrial Ribbon Blender

Most ribbon blender machines share the same core components. If you want the best mixing results, you should understand what those parts are and what each one does.

U-shaped trough: This is the U-shaped, horizontal mixing tank where the blending happens. You load ingredients from the top. The inner surfaces have a smooth finish to reduce buildup and make cleaning easier. The curved design and a fitted lid help keep material contained during mixing.

Shaft and ribbons: The shaft runs through the center of the trough. Ribbons can be a single spiral or a pair of inner and outer helices. They are the so-called agitator fixed to the shaft to do the mixing. The ribbon shape and pitch control how fast and how gentle the blending action can be.

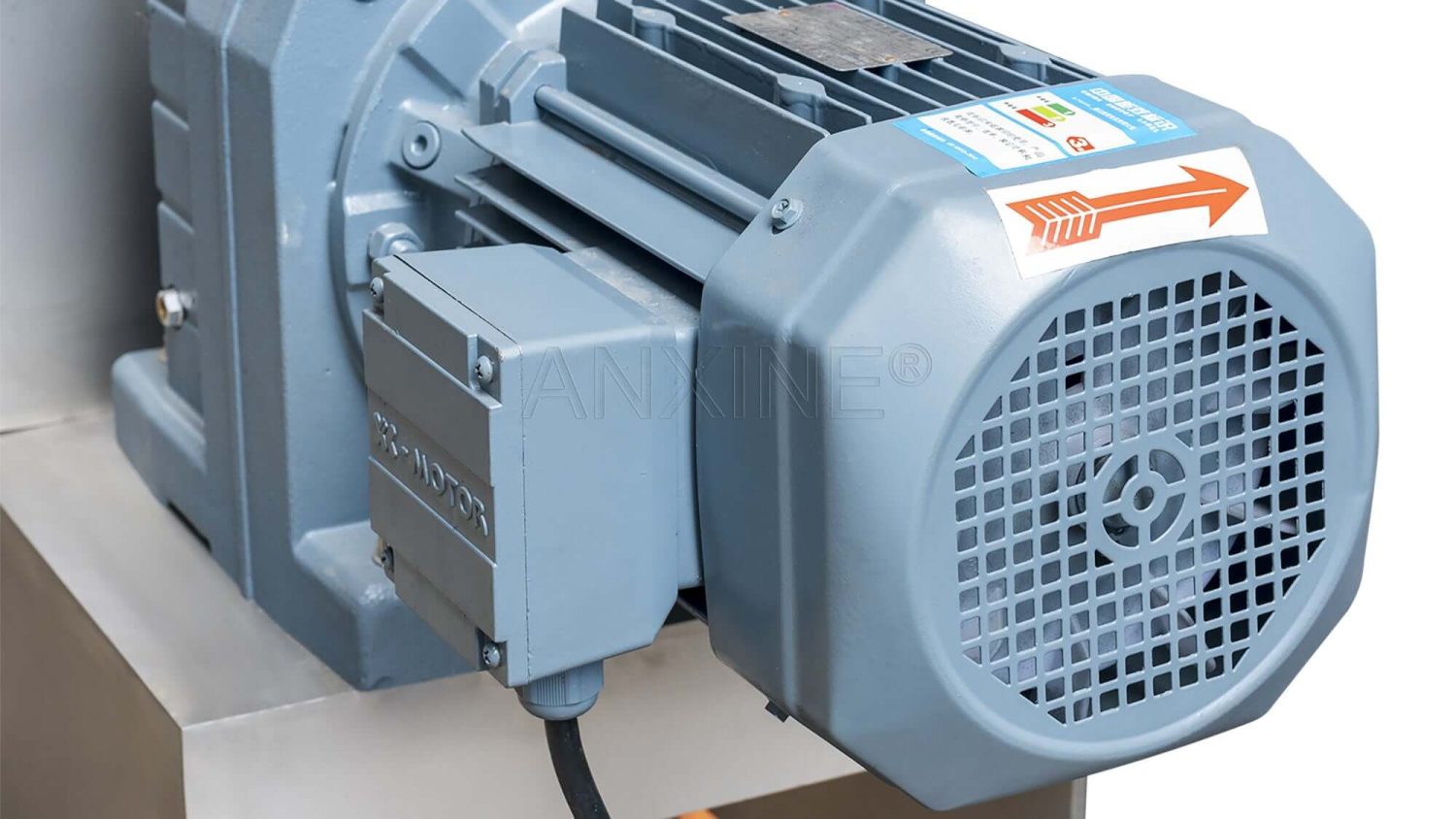

Drive system and motor: The electric motor rotates the central shaft and ribbons to move the material inside the trough. This creates the tumbling and folding action needed for blending. The variable speed drive lets you adjust the speed of the ribbon agitator for different products.

Covers and safety grates: The hinged cover lets you add ingredients and check the blend. Many ribbon blenders also use safety grates or interlocks to help protect operators while the machine is running.

Discharge valve: This component is often located at the bottom of the trough. It’s an outlet fitted with a butterfly valve or a slide gate. A well-designed discharge helps most of the material to flow out quickly.

How Ribbon Blending Happens Inside the Trough

Let’s take a double ribbon blender as an example.

When you turn on the ribbon blender, the motor rotates the ribbon agitator. The outer ribbons push material from both ends of the trough toward the center. The inner ribbons move material from the center out to the ends.

At the same time, material is lifted and dropped. These movements break up small lumps and force particles to mix and remix until the whole batch is uniform. And then you can empty out a perfect blend.

Curious about the full step-by-step process? You’ll enjoy this article: Understanding the Ribbon Blender Working Principle.

Ribbon Blender Advantages and Disadvantages

Key Advantages of Ribbon Blenders

- Plenty of options: Industrial models are available from small lab units to large industrial systems.

- Versatile material handling: They can handle powders, granules, and minor liquid addition in one machine.

- Fast, uniform mixing: They’re very effective at producing a uniform mix. The ribbon agitator can create a blend in 5-15 minutes.

- Budget-friendly: Ribbon blenders have fewer moving parts and lower energy use than other complex mixers. This makes them a cost-effective choice.

Main Limitations of a Ribbon Blender

- Harsh mixing action: The mixing action can be aggressive. So the machine may not be suitable for delicate or brittle ingredients.

- Limited liquid handling: Ribbon blenders work fine with small amounts of liquid, but too much can form clumps. The agitator may struggle, and the motor load rises quickly.

- Risk of dead spots: They must be loaded properly. If underfilled or overfilled, or if the ribbon design is poor, you might get areas that don’t mix.

- Time-consuming cleanup: Cleaning a ribbon blender can be labor-intensive, especially for the inner and outer helical models.

Ribbon Blender Uses & Applications

You’ll find ribbon blenders are used anywhere you need to mix dry bulk materials into a uniform blend. Pharma and nutra are among the biggest markets.

Common Pharma and Nutra Applications

Tablet and capsule blends: Mixing active ingredients with binders, diluents, lubricants, and other excipients before you load them into a tablet press or capsule filling machine.

Vitamin and mineral premixes: Creating master premixes with micro-dose ingredients that are later diluted into food or beverage bases.

Protein powders and meal replacement mixes: Blending proteins, functional fibers, sweeteners, flavors, and colors into a uniform powder mix.

Herbal and botanical blends: Combining different dry granules and powders or delicate herbs and leaves into a free-flowing mixture.

Other Typical Ribbon Blender Uses

Food Products: Spice blends, bakery mixes, and drink powders. Ribbon blenders can gently fold these ingredients to preserve their flavors and aromas.

Chemicals: Fertilizers, detergents, polymers, and plastic additives. Most ribbon blenders are made of stainless steel, which gives them a robust construction to handle many chemical powders and granules.

Cosmetics & Personal Care: Face powder, foundation bases, bath salts, tooth powder, etc. Beyond making a uniform base blend, the machine can evenly mix in pigments and fragrances in these products.

That said, there are a few application-specific watch-outs worth noting. Ribbon blenders work best with free-flowing, dry materials. If you’re dealing with hygroscopic or heat-sensitive ingredients, you’ll usually need a more specialized design, like a jacketed trough, to help control temperature.

And if your material is very sticky or fragile, a paddle blender can sometimes be the safer choice. So what’s the difference between a ribbon blender and a paddle blender? Let’s find out!

Ribbon Blender vs Paddle Blender

At first glance, ribbon blenders and paddle blenders look very similar because they both use a U-shaped trough. The real differences are hidden inside.

| Ribbon Blender | Feature | Paddle Blender |

| Single or double helical ribbons on a central shaft. | Agitator Design | Flat or slightly curved paddles mounted at angles on the shaft. |

| Stir and fold in opposite directions. More aggressive. | Mixing Action | Scoop and toss in a tumbling motion. More gentle. |

| Generally faster. Can create a uniform blend in minutes. | Mixing Speed | Typically slower. Take longer to reach the same uniformity. |

| Dry, free-flowing powders and granules. | Best For | Fragile, sticky, or abrasive ingredients. |

| More internal surfaces inside. Potential small residues on the ribbons and discharging port. All this makes cleaning a bit more involved. | Ease of Cleaning | Fewer intricate parts inside. Have large access doors for quick discharge. Usually easier to clean. |

| Tablet and capsule blends, spice mixes, detergent powders, bulk dry premixes | Typical Uses | Nut and cereal mixes, pet food, slurries, doughs, cohesive or heat-sensitive mixes |

Ribbon Blender FAQs

Q1. What is the typical mixing time in a ribbon blender?

A: About 5 to 15 minutes. It’s quite fast. Many ribbon blender batches can reach a uniform mix within that window. Of course, the exact time depends on the ingredients you’re blending.

Q2. What fill level should I target in an industrial ribbon blender?

A: The optimal fill level is around 40 to 70% of its total volume. Try not to go below 30%, or you’ll end up with poor mixing because the ribbons don’t have enough product to move. Also, over 90% is usually a bad idea too. Even if some makers claim 100% fill, that’s rarely practical because there’s no free space for the material to tumble.

Q3. Can a ribbon blender mix liquids into powders?

A: Yes, many ribbon blenders are effective at coating particles with small amounts of liquid. Usually, these blenders feature a spray bar or an injection port in the cover. The key is to keep the liquid level low. If you add too much, the mix can clump.

Q4. When should I choose a paddle blender instead of a ribbon blender?

A: A paddle blender is known for its gentle tumbling action. So it’s usually a better choice when you are working with delicate or heat-sensitive ingredients. It’s also ideal for folding liquids into solids when you need to make doughs or slurries.